16

2025

-

08

Why Coated Precipitated Calcium Carbonate is Essential for Modern Manufacturing

Introduction to Coated Precipitated Calcium Carbonate in Manufacturing Coated precipitated calcium carbonate (PCC) has emerged as a crucial component in many manufacturing processes. Our modern industrial landscape demands materials that not only meet stringent quality standards but also contribute to overall operational efficiency. Coated PCC serves as a versatile filler and functional additive

Introduction to Coated Precipitated Calcium Carbonate in Manufacturing

Coated precipitated calcium carbonate (PCC) has emerged as a crucial component in many manufacturing processes. Our modern industrial landscape demands materials that not only meet stringent quality standards but also contribute to overall operational efficiency. Coated PCC serves as a versatile filler and functional additive, enhancing the physical properties of products while driving down costs. Understanding its significance will provide insight into why this material is essential for today’s manufacturing businesses.

What is Coated Precipitated Calcium Carbonate?

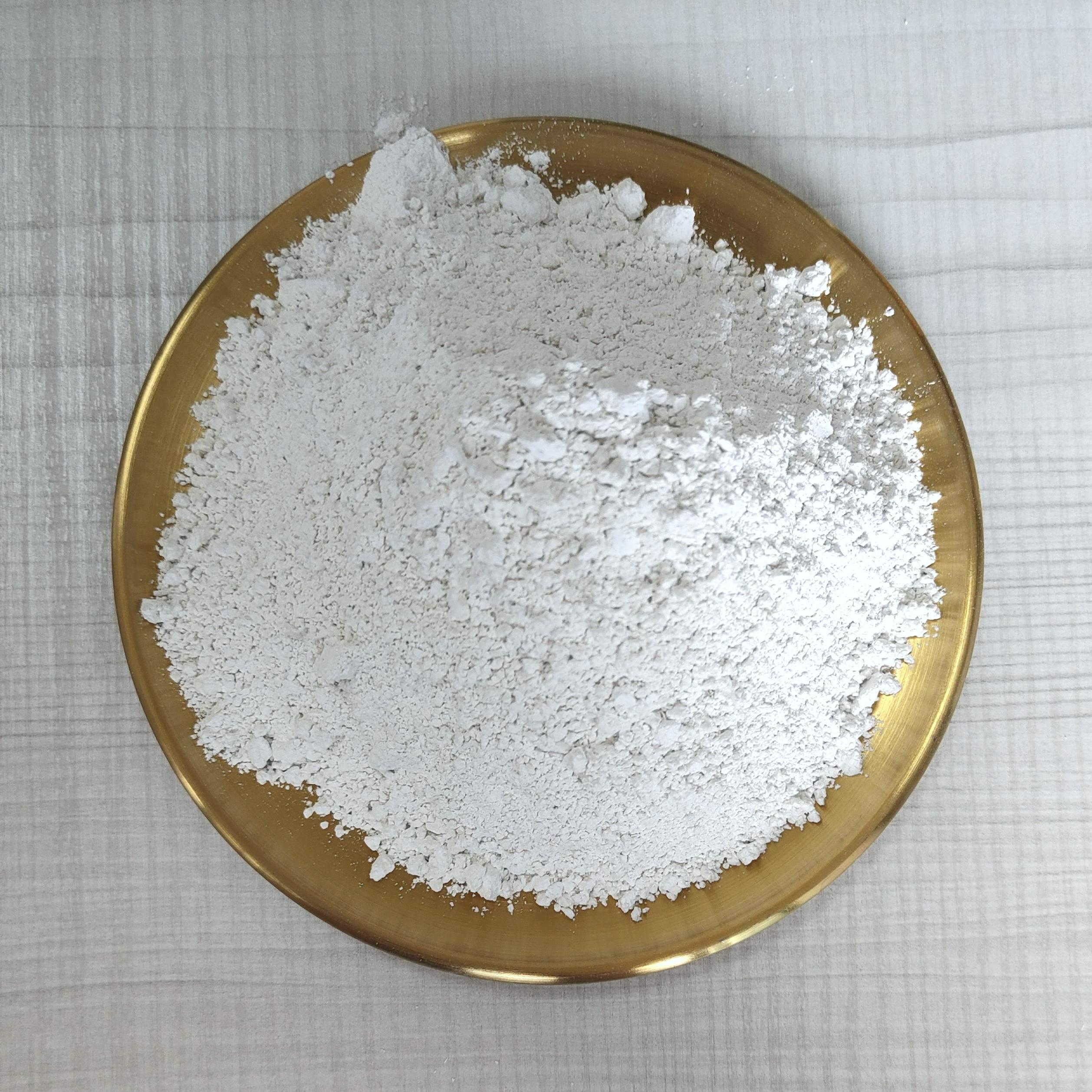

Coated precipitated calcium carbonate is a synthetic form of calcium carbonate that is produced through a process of precipitation. This process involves the reaction of calcium compounds with carbon dioxide in a controlled environment, resulting in fine particles with a high degree of purity. The “coating” aspect refers to the application of a surface treatment, often using stearic acid or other organic compounds, which improves its compatibility with polymers and other materials.

The Production Process of Coated PCC

The production of coated PCC involves several key steps:

1. **Calcium Source Preparation**: The process begins with the selection of high-purity calcium sources, such as calcium oxide or calcium hydroxide.

2. **Carbonation**: The calcium compounds are reacted with carbon dioxide in a reactor, leading to the formation of calcium carbonate.

3. **Precipitation and Filtration**: The calcium carbonate precipitates out of the solution and is subsequently filtered to remove excess water and impurities.

4. **Coating**: The filtered PCC is then treated with hydrophobic agents, typically fatty acids, to enhance its performance in various applications.

5. **Drying and Milling**: Finally, the coated PCC is dried and milled to achieve the desired particle size and distribution.

Key Properties of Coated Precipitated Calcium Carbonate

Coated PCC boasts several properties that make it particularly advantageous for use in manufacturing:

- **Particle Size and Distribution**: The fine and uniform particle size of coated PCC allows for better dispersion in various matrices, improving overall material performance.

- **Enhanced Compatibility**: The coating improves the hydrophobic nature of the particles, ensuring they blend well with different polymers and resins.

- **High Purity**: The production process ensures that coated PCC has a high level of purity, making it suitable for applications where contaminant levels must be minimized.

- **Improved Mechanical Properties**: Coated PCC can enhance the tensile strength, impact resistance, and durability of composite materials, leading to better end-product performance.

Applications of Coated Precipitated Calcium Carbonate

The versatility of coated PCC allows it to be used across various industries. Here are some of its most common applications:

1. Plastics Industry

In the plastics sector, coated PCC is used as a filler in the production of films, sheets, and molded products. Its ability to improve mechanical properties while reducing material costs makes it a preferred choice among manufacturers.

2. Paint and Coatings

Coated PCC is widely employed in the formulation of paints and coatings. It enhances opacity, brightness, and texture, leading to superior surface finishes and improved application performance.

3. Paper Industry

In the paper manufacturing process, coated PCC acts as a filler and coating pigment. It enhances the brightness and smoothness of paper products while also improving printability.

4. Rubber Manufacturing

Within the rubber industry, coated PCC is utilized in the production of tires and other rubber products. It enhances flexibility, reduces rolling resistance, and improves overall durability.

5. Food Industry

Coated PCC is also used as an additive in food products, where it serves as an anti-caking agent and improves the flow properties of powdered materials.

Benefits of Using Coated Precipitated Calcium Carbonate in Manufacturing

Integrating coated PCC into manufacturing processes offers numerous advantages:

Cost Efficiency

By substituting more expensive raw materials with coated PCC, manufacturers can significantly reduce production costs without compromising product quality.

Enhanced Performance

The unique properties of coated PCC contribute to improved mechanical performance in finished products. This leads to higher durability and longevity, which can ultimately reduce warranty claims and improve customer satisfaction.

Sustainability

Coated PCC production processes can be more environmentally friendly compared to the extraction of traditional mineral fillers. Moreover, the use of coated PCC can enhance the recyclability of certain products.

Challenges in the Use of Coated Precipitated Calcium Carbonate

While coated PCC has many benefits, it is not without challenges. Some manufacturers may face difficulties in achieving the desired dispersion and compatibility in certain applications. Additionally, the initial investment required for high-quality coated PCC can be a barrier for smaller manufacturers.

Future Trends in Coated Precipitated Calcium Carbonate

As technology advances, the development of even more effective coated PCC formulations is on the horizon. Innovations may include:

- **Nanotechnology**: Exploring nano-scale coatings to further enhance the performance of coated PCC.

- **Biodegradable Coatings**: Developing sustainable and eco-friendly coating materials that can further improve the environmental profile of PCC.

- **Customized Solutions**: Offering tailored solutions to meet specific industry needs and challenges.

FAQs about Coated Precipitated Calcium Carbonate

1. What is the difference between coated and uncoated precipitated calcium carbonate?

Coated PCC has a hydrophobic surface treatment, enhancing its compatibility with various materials, while uncoated PCC is more hydrophilic and may not perform as well in certain applications.

2. How does coated PCC improve product performance?

Coated PCC enhances mechanical properties, improves dispersion, and can provide a smoother finish in end products, leading to better overall performance.

3. Is coated precipitated calcium carbonate safe for food applications?

Yes, coated PCC is widely used as a food additive and is considered safe for consumption when used within regulatory guidelines.

4. Can coated PCC be recycled?

Coated PCC can improve the recyclability of certain products, though the recyclability largely depends on the overall formulation and processing methods.

5. How is the quality of coated PCC ensured during production?

Quality control measures, including rigorous testing of raw materials and finished products, are essential to ensure that coated PCC meets industry standards for purity and performance.

Conclusion

Coated precipitated calcium carbonate stands out as a crucial element in modern manufacturing. Its unique properties and wide range of applications not only enhance product performance but also drive cost efficiency and sustainability. As industries continue to evolve, the role of coated PCC will only become more significant, making it an essential material for manufacturers aiming to stay competitive in a fast-paced market. Embracing this versatile additive can lead to better, more durable products that meet the demands of today’s consumers.

coated precipitated calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.