22

2025

-

08

Unlocking the Potential of Coated Precipitated Calcium Carbonate in Adhesives

Unlocking the Potential of Coated Precipitated Calcium Carbonate in Adhesives Table of Contents 1. Introduction to Coated Precipitated Calcium Carbonate 2. The Role of Coated PCC in Adhesives 3. Advantages of Using Coated PCC in Adhesive Formulations 3.1 Improved Mechanical Properties 3.2 Enhanced Rheological Behavior 3.3 Cost Efficiency 3.4 Environmental Benefits 4. Applications

Unlocking the Potential of Coated Precipitated Calcium Carbonate in Adhesives

Table of Contents

1. Introduction to Coated Precipitated Calcium Carbonate

2. The Role of Coated PCC in Adhesives

3. Advantages of Using Coated PCC in Adhesive Formulations

3.1 Improved Mechanical Properties

3.2 Enhanced Rheological Behavior

3.3 Cost Efficiency

3.4 Environmental Benefits

4. Applications of Coated PCC in Adhesives

4.1 Construction Adhesives

4.2 Packaging Adhesives

4.3 Automotive Adhesives

5. Factors Influencing the Performance of Coated PCC in Adhesives

6. Future Trends in Coated PCC for Adhesive Applications

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction to Coated Precipitated Calcium Carbonate

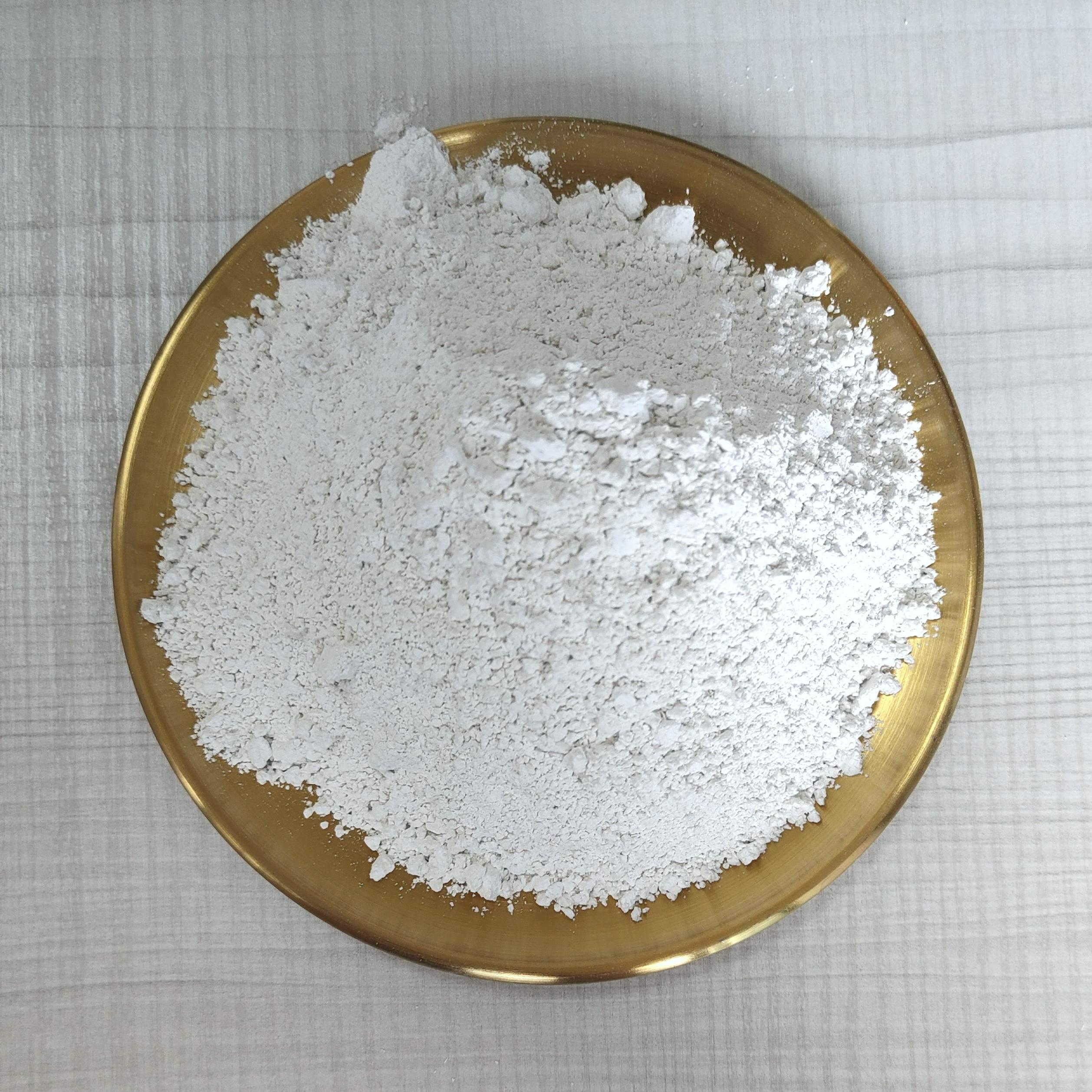

Coated precipitated calcium carbonate (PCC) has emerged as a vital ingredient in various industries, especially in the formulation of adhesives. As a versatile mineral, PCC is produced through the carbonation of calcium hydroxide and is characterized by its fine, spherical particles. When coated, it exhibits enhanced properties that significantly improve the performance of adhesives. This article aims to explore the potential that coated PCC holds for adhesive manufacturers and formulators.

2. The Role of Coated PCC in Adhesives

Coated PCC serves multiple roles in adhesive formulations. Its primary function is to act as a filler, improving the bulk and viscosity of the adhesive without compromising its adhesive properties. The coating on PCC enhances its compatibility with various polymers and resins, leading to a more homogenous mixture. This compatibility ensures that the adhesive maintains a consistent application performance, which is crucial for both manufacturers and end-users.

3. Advantages of Using Coated PCC in Adhesive Formulations

The incorporation of coated PCC into adhesives brings forth numerous advantages.

3.1 Improved Mechanical Properties

Using coated PCC enhances the mechanical properties of adhesives, including tensile strength and elasticity. The spherical shape of PCC particles allows for uniform stress distribution within the adhesive matrix, leading to improved bonding strength.

3.2 Enhanced Rheological Behavior

Coated PCC helps in achieving optimal rheological behavior, crucial for the easy application of adhesives. The material can modify viscosity, allowing the adhesive to spread evenly and adhere effectively to various surfaces.

3.3 Cost Efficiency

One of the most significant advantages of using coated PCC is cost efficiency. The low cost of PCC compared to synthetic fillers means that manufacturers can achieve the desired performance characteristics without significantly increasing production costs.

3.4 Environmental Benefits

Coated PCC is an environmentally friendly option, as it is derived from natural resources. Its use in adhesives contributes to more sustainable practices within the manufacturing processes, aligning with the growing demand for eco-friendly products.

4. Applications of Coated PCC in Adhesives

Coated PCC finds applications across various types of adhesives, making it a versatile ingredient.

4.1 Construction Adhesives

In the construction industry, coated PCC is utilized in adhesives for tiles, flooring, and panels. Its enhanced strength and durability make it ideal for demanding applications.

4.2 Packaging Adhesives

Coated PCC is also prevalent in packaging adhesives, where it aids in creating strong bonds that withstand various environmental conditions while being lightweight.

4.3 Automotive Adhesives

In automotive applications, coated PCC enhances the performance of adhesives used in vehicles. Its contribution to weight reduction and improved bonding strength is essential for fuel efficiency and structural integrity.

5. Factors Influencing the Performance of Coated PCC in Adhesives

Several factors can influence the performance of coated PCC in adhesives, including particle size, coating material, and the proportion of PCC in the formulation. Understanding these factors is essential for manufacturers to optimize their adhesive products for specific applications.

6. Future Trends in Coated PCC for Adhesive Applications

The future of coated PCC in the adhesive industry is promising, with ongoing research focusing on enhancing its properties further. Innovations in coating technologies and the exploration of new applications are expected to drive growth in this segment. As sustainability becomes increasingly important, the demand for eco-friendly fillers like coated PCC is likely to rise.

7. Frequently Asked Questions (FAQs)

**Q1: What is coated precipitated calcium carbonate?**

A1: Coated PCC is a fine, white powder produced from the carbonation of calcium hydroxide, with a coating that enhances its properties for various applications, particularly in adhesives.

**Q2: How does coated PCC improve adhesive performance?**

A2: Coated PCC improves adhesive performance by enhancing mechanical properties, providing optimal viscosity, and ensuring compatibility with various polymers.

**Q3: Is coated PCC environmentally friendly?**

A3: Yes, coated PCC is derived from natural resources and promotes more sustainable manufacturing practices.

**Q4: What are the main industries that use coated PCC in adhesives?**

A4: Coated PCC is primarily used in the construction, packaging, and automotive industries.

**Q5: How can manufacturers optimize their adhesive formulations using coated PCC?**

A5: Manufacturers can optimize adhesive formulations by adjusting the particle size, coating materials, and proportions of coated PCC to achieve desired performance characteristics.

8. Conclusion

Coated precipitated calcium carbonate stands as a game-changer in the adhesive industry, providing numerous benefits ranging from enhanced mechanical properties to cost efficiency and environmental sustainability. As manufacturers continue to seek innovative solutions for improving adhesive performance, the potential of coated PCC will only continue to grow. Embracing this versatile material not only aligns with the trend toward eco-friendly practices but also positions manufacturers at the forefront of industry advancements. The future of adhesives lies in optimizing formulations with high-quality fillers like coated PCC, ensuring lasting bonds that meet the demands of various applications.

coated precipitated calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.