19

2025

-

08

Understanding Coated Precipitated Calcium Carbonate: Applications and Benefits

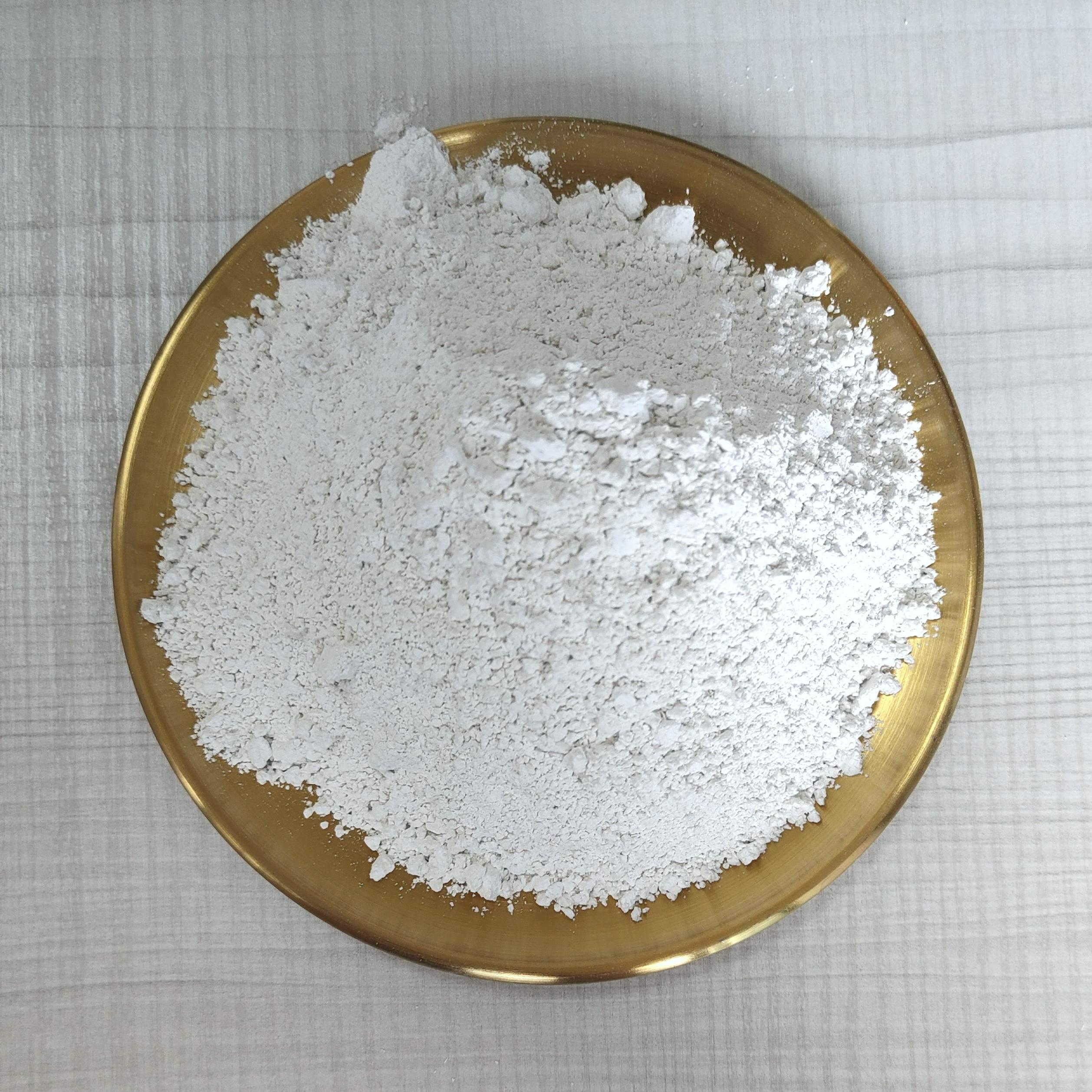

Coated precipitated calcium carbonate (PCC) is an advanced form of calcium carbonate that has been treated with specific surfactants to enhance its performance in various applications. This innovative material is produced through a controlled chemical process that involves the precipitation of calcium carbonate from calcium-containing solutions. The result is a fine, white powder with unique prope

One of the critical advantages of coated PCC is its improved dispersion and compatibility with other materials. The coating process alters the surface characteristics of the calcium carbonate particles, enabling them to better integrate into various matrices. This feature is particularly beneficial in applications such as polymer composites, where even distribution of fillers is vital for achieving optimal mechanical properties.

In the paint and coating industry, coated PCC serves as an excellent extender and filler, enhancing the opacity and brightness of finished products. Its fine particle size and uniform distribution contribute to improved gloss and a smoother texture, making it an attractive choice for manufacturers. Furthermore, using coated PCC in paint formulations can help reduce production costs while maintaining a high-quality appearance.

In the paper industry, coated PCC is prized for its ability to improve printability and brightness. The fine particles can fill voids in the paper matrix, leading to enhanced surface smoothness and ink adhesion. Additionally, the use of coated PCC can contribute to reducing the amount of wood pulp needed in paper production, promoting more sustainable practices within the industry.

The versatility of coated PCC extends to the rubber industry, where it is used to improve the elasticity and tensile strength of rubber compounds. The surface treatment enhances the interaction between the calcium carbonate and rubber polymers, resulting in improved performance characteristics of the final products. This property is crucial for applications in tires, seals, and other rubber goods, where durability and reliability are paramount.

Moreover, the use of coated precipitated calcium carbonate can have environmental benefits. By substituting a portion of more expensive or less environmentally friendly materials with coated PCC, manufacturers can produce more sustainable products without sacrificing quality. The abundance and low toxicity of calcium carbonate further support its role as a viable alternative in various applications.

In summary, coated precipitated calcium carbonate is a multifaceted material that offers significant advantages across several industries. Its unique properties, including improved dispersion, enhanced compatibility, and sustainable advantages, make it an essential component in many formulations. As industries continue to seek innovative solutions, coated PCC stands out as a valuable resource in the quest for quality and efficiency in chemical products.

coated precipitated calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.