13

2025

-

08

Understanding Coated Precipitated Calcium Carbonate: A Versatile Additive in the Chemical Industry

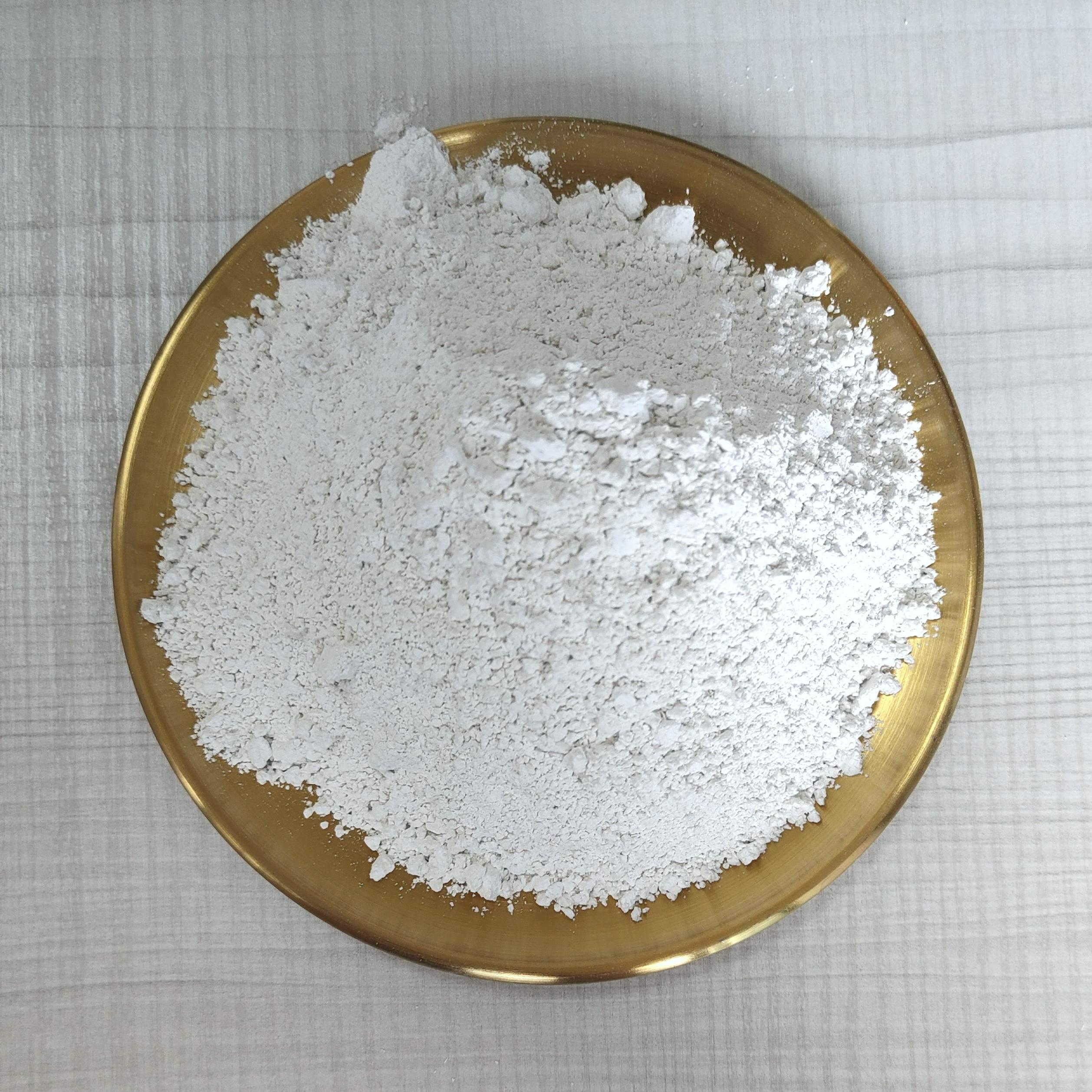

Coated precipitated calcium carbonate (CPCC) is a specialized form of calcium carbonate that is treated with surface coatings, enhancing its properties and expanding its range of applications. As a product of the chemical industry, CPCC is derived from natural limestone and undergoes a precipitation process to achieve a fine, pure crystal structure. The coating process typically involves the appli

One of the primary advantages of coated precipitated calcium carbonate is its improved dispersibility, which allows for better integration into different matrices, including polymers, paints, and coatings. This enhanced dispersibility results from the modified surface characteristics, which reduce agglomeration tendencies. Consequently, manufacturers can achieve a more uniform product with consistent performance, which is crucial for high-quality applications in industries such as plastics, paints, and sealants.

Furthermore, CPCC acts as a filler and extender, helping to reduce production costs while maintaining or improving product quality. By substituting a portion of more expensive materials with coated precipitated calcium carbonate, manufacturers can optimize their formulations. This cost-effective approach is particularly advantageous in the production of coatings and adhesives, where performance and cost-efficiency are essential.

In addition to its economic benefits, coated precipitated calcium carbonate contributes to environmental sustainability. As a naturally occurring mineral, it is abundant and can be sourced with a relatively low environmental impact compared to synthetic alternatives. The use of CPCC in various applications helps reduce the carbon footprint of products, aligning with the industry's shift towards more sustainable manufacturing practices.

Moreover, the versatility of coated precipitated calcium carbonate allows it to be utilized in a diverse range of applications. In the paper industry, it enhances brightness and opacity, while in the rubber industry, it improves durability and flexibility. Additionally, in the food and pharmaceutical sectors, CPCC can be employed as an excipient due to its safe and non-toxic nature.

In summary, coated precipitated calcium carbonate is an innovative and versatile additive that plays a significant role in various industries. Its unique properties, including enhanced dispersibility, cost-effectiveness, and environmental sustainability, make it an essential component in modern manufacturing processes. As industries continue to evolve, the demand for high-performance materials like CPCC will likely increase, driving further advancements in its applications and formulations. By understanding the benefits and uses of coated precipitated calcium carbonate, manufacturers can make informed decisions that optimize their products and contribute to sustainable practices in the chemical industry.

coated precipitated calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.