10

2025

-

08

Exploring the Benefits of Coated Precipitated Calcium Carbonate in Various Industries

Exploring the Benefits of Coated Precipitated Calcium Carbonate in Various Industries Table of Contents 1. Introduction to Coated Precipitated Calcium Carbonate 2. What is Coated Precipitated Calcium Carbonate? 3. The Manufacturing Process of Coated PCC 4. Key Advantages of Coated PCC 4.1 Enhanced Performance in Products 4.2 Cost-Effectiveness

Exploring the Benefits of Coated Precipitated Calcium Carbonate in Various Industries

Table of Contents

- 1. Introduction to Coated Precipitated Calcium Carbonate

- 2. What is Coated Precipitated Calcium Carbonate?

- 3. The Manufacturing Process of Coated PCC

- 4. Key Advantages of Coated PCC

- 5. Applications of Coated Precipitated Calcium Carbonate

- 6. Future Trends in Coated PCC

- 7. Conclusion

- 8. Frequently Asked Questions

1. Introduction to Coated Precipitated Calcium Carbonate

Coated precipitated calcium carbonate (PCC) has emerged as a versatile additive across numerous industries. Its unique properties make it an invaluable resource in enhancing the performance of various products. In this article, we will delve into the myriad benefits of coated PCC, exploring its manufacturing process, applications, and future trends.

2. What is Coated Precipitated Calcium Carbonate?

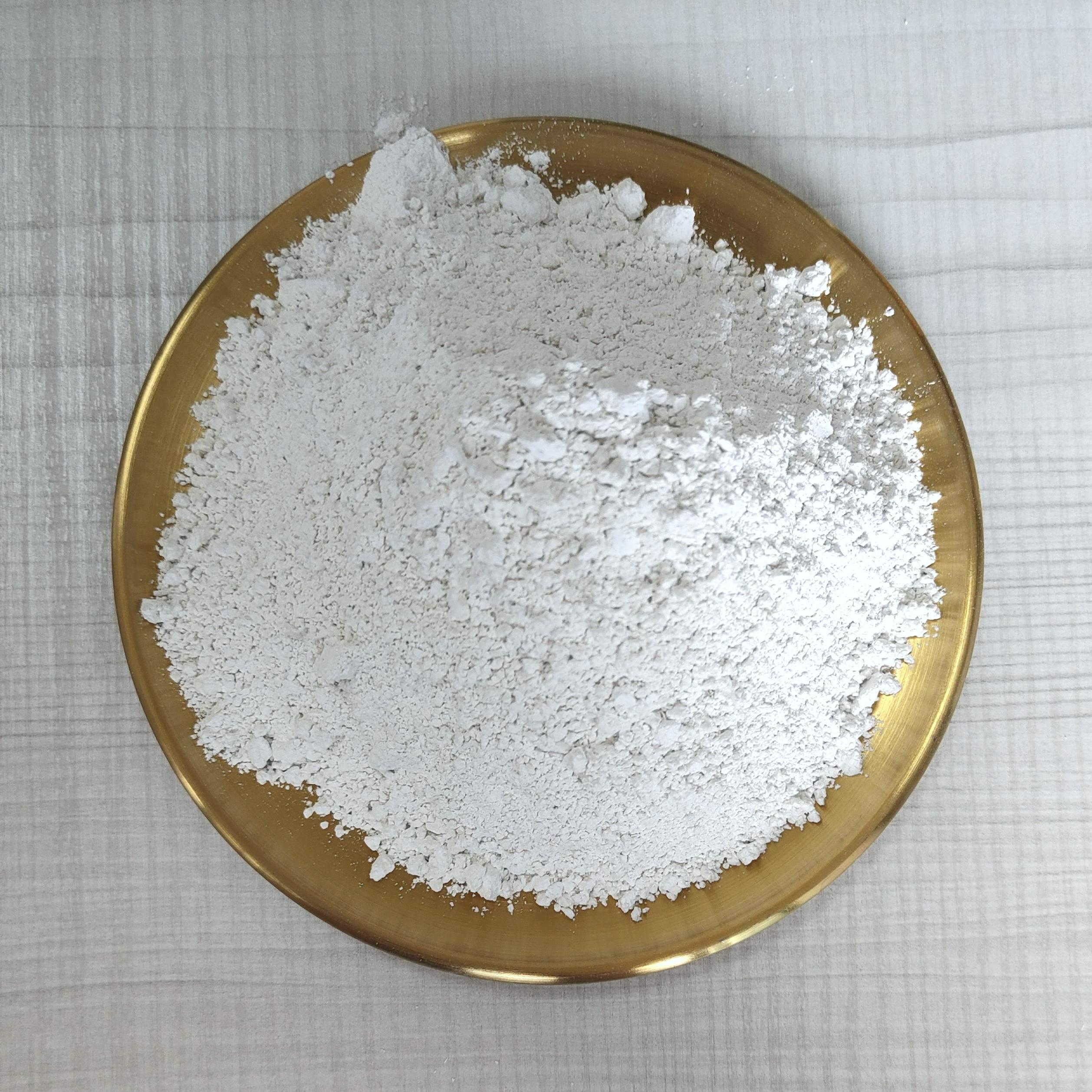

Coated precipitated calcium carbonate is a refined form of calcium carbonate that undergoes a precipitation process, followed by a coating process with substances such as stearic acid. This coating enhances its surface characteristics, improving its compatibility with polymers and other materials. The result is a product that boasts superior dispersion, lower viscosity, and better UV stability, making it an ideal choice for various applications.

3. The Manufacturing Process of Coated PCC

The production of coated PCC involves several critical steps:

1. **Precipitation**: Calcium carbonate is precipitated from a solution containing calcium ions and carbonate ions. This involves the controlled reaction of these ions in a reactor to form fine calcium carbonate particles.

2. **Washing and Filtration**: The precipitated calcium carbonate is then washed to remove impurities and unreacted materials. After washing, it is filtered to obtain a concentrated slurry.

3. **Drying**: The slurry is dried to produce a fine powder of precipitated calcium carbonate.

4. **Coating**: In this step, the dry PCC powder is coated with agents like stearic acid. This process enhances the hydrophobic properties of the carbonate, improving its performance in various applications.

5. **Quality Control**: The final product undergoes rigorous quality control measures to ensure it meets industry standards and specifications.

4. Key Advantages of Coated PCC

Coated precipitated calcium carbonate offers several distinct advantages that make it a preferred choice for many industries.

4.1 Enhanced Performance in Products

The coating applied to PCC significantly enhances its performance. Coated PCC exhibits improved flowability and dispersion characteristics, allowing for better integration into products without clumping. This property is particularly beneficial in applications such as paints and coatings, where uniform distribution is critical for achieving desired aesthetic and functional properties.

4.2 Cost-Effectiveness

Using coated PCC can lead to substantial cost savings for manufacturers. Its ability to replace more expensive materials without compromising quality helps reduce production costs. Additionally, the enhanced performance of coated PCC can lead to increased efficiency in manufacturing processes, further driving down costs.

4.3 Environmental Benefits

Coated PCC is an environmentally friendly alternative to synthetic additives. Its use can reduce the reliance on petroleum-based products, contributing to more sustainable manufacturing practices. Moreover, the natural abundance of calcium carbonate means that it is a renewable resource, making it a more sustainable choice in the long run.

5. Applications of Coated Precipitated Calcium Carbonate

The versatility of coated PCC allows for its application across various industries. Here, we explore some of the primary sectors that benefit from this remarkable material.

5.1 Use in Paints and Coatings

In the paints and coatings industry, coated PCC is invaluable. It serves as a filler that enhances the opacity, brightness, and durability of paints. The fine particle size and controlled surface properties ensure that the coatings have excellent flow and leveling characteristics, resulting in a superior finish.

5.2 Applications in Plastics

Coated PCC is widely used in the plastics industry as a functional filler that improves the mechanical properties of plastic products. It enhances strength, reduces production costs, and improves the overall durability of plastic items. The compatibility of coated PCC with various polymer matrices makes it a go-to choice for manufacturers looking to improve their product performance.

5.3 Significance in the Rubber Industry

In the rubber industry, coated PCC acts as a reinforcing agent that improves elasticity and tensile strength. Its incorporation into rubber compounds results in products that exhibit better wear resistance and flexibility. This has made coated PCC a crucial component in the production of tires, seals, and various rubber goods.

5.4 Role in Food and Pharmaceuticals

Coated PCC finds applications in the food and pharmaceutical industries as an anti-caking agent, bulking agent, and stabilizer. Its inert nature and safety profile make it suitable for use in food products and dietary supplements, where it enhances texture and helps maintain product quality over time.

6. Future Trends in Coated PCC

As industries evolve, the demand for coated precipitated calcium carbonate will likely continue to grow. Future trends include:

- **Innovative Coating Technologies**: Advancements in coating technologies will lead to customized PCC products tailored for specific applications, enhancing performance and functionality.

- **Sustainable Practices**: As industries push for greener practices, the demand for eco-friendly additives like coated PCC will rise, making it a vital component in sustainable manufacturing.

- **Expanding Applications**: Research and development will likely unveil new applications for coated PCC, particularly in emerging sectors such as nanotechnology and smart materials, where its unique properties can be leveraged for innovative solutions.

7. Conclusion

Coated precipitated calcium carbonate stands as a testament to innovation in material science, offering unparalleled benefits across diverse industries. Its enhancements in product performance, cost-effectiveness, and eco-friendliness make it an indispensable additive for manufacturers. As we continue to explore its potential, coated PCC is poised to play a significant role in shaping the future of various industries.

8. Frequently Asked Questions

What is the primary use of coated precipitated calcium carbonate?

Coated precipitated calcium carbonate is primarily used as a functional filler in industries such as paints, plastics, rubber, and food, enhancing product quality and performance.

How does coated PCC improve product performance?

The coating on PCC enhances its surface properties, allowing for better dispersion, lower viscosity, and improved compatibility with other materials, leading to superior product performance.

Is coated PCC environmentally friendly?

Yes, coated PCC is considered environmentally friendly as it is a natural mineral resource that reduces the reliance on synthetic additives, promoting sustainable manufacturing practices.

Can coated PCC be used in food products?

Absolutely! Coated PCC is safe for use in food products and is commonly used as an anti-caking and bulking agent in various food applications.

What future developments can we expect in coated PCC?

Future developments may include advancements in coating technologies, new applications in emerging industries, and a continued focus on sustainable practices, making coated PCC a crucial material for innovation.

coated precipitated calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.