20

2025

-

07

Unlocking the Potential of Colloidal Nano Calcium Carbonate: A Comprehensive Guide

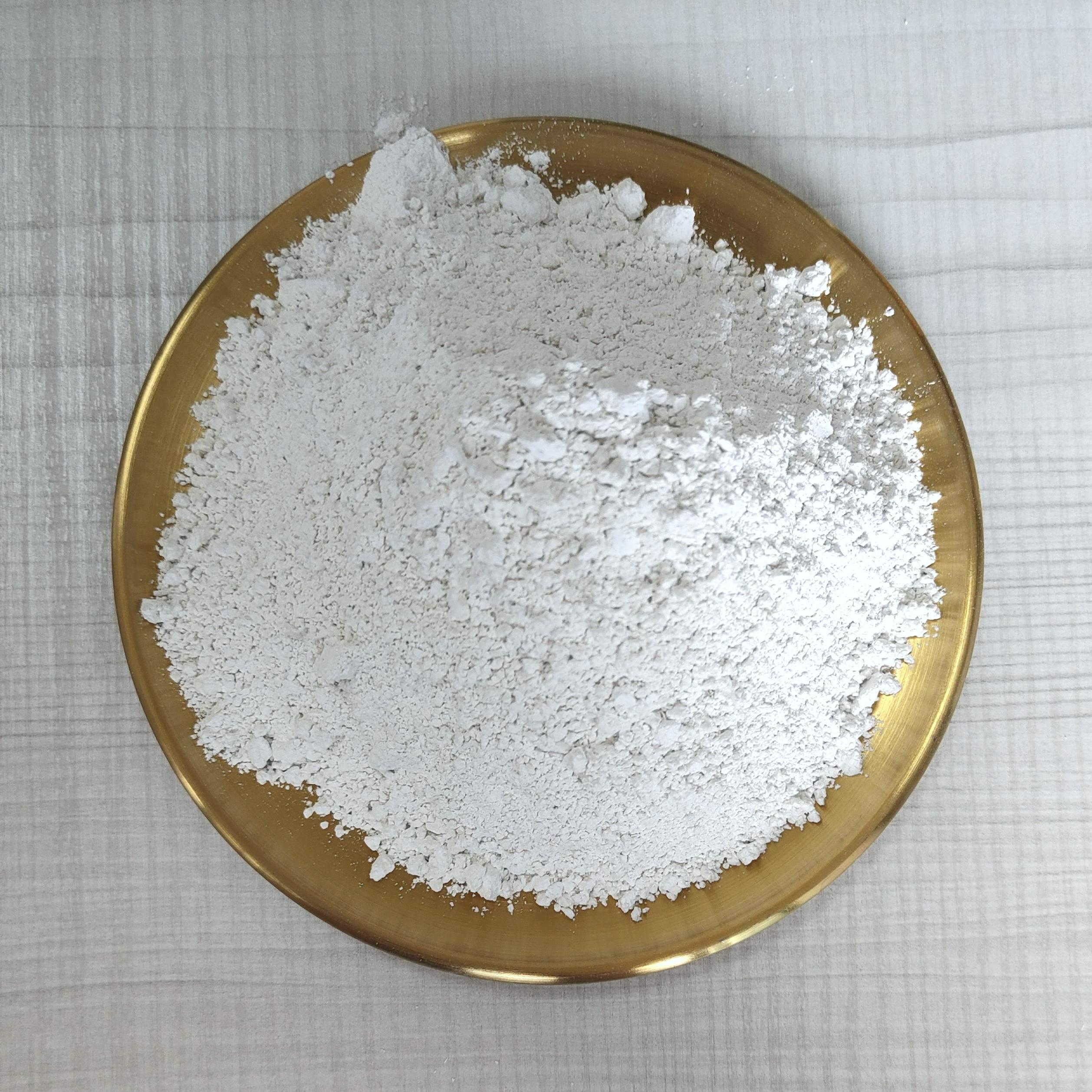

Colloidal nano calcium carbonate (CNC) is gaining significant attention in the chemical industry, particularly within the pigments and dyes sector. This specialized form of calcium carbonate is characterized by its extremely fine particles, typically in the nanometer size range. The small particle size endows colloidal nano calcium carbonate with unique properties that make it an attractive option

One of the most notable attributes of colloidal nano calcium carbonate is its high surface area to volume ratio. This characteristic results in enhanced reactivity and improved dispersion in different mediums, which is particularly beneficial in paint and coating applications. The increased surface area allows for better adhesion and a smoother finish, ultimately leading to improved product performance. As a result, many manufacturers are increasingly integrating CNC into their formulations to achieve superior quality and durability in their products.

Beyond its use in coatings, colloidal nano calcium carbonate is also recognized for its ability to act as a filler and a whitening agent. In the pigment and dye industry, CNC can help in producing vibrant colors and achieving the desired opacity. Its fine particle size allows for a more uniform distribution within the formulation, which can enhance the overall aesthetic appeal of the final product.

Moreover, colloidal nano calcium carbonate is valued for its low toxicity and environmentally friendly profile. As industries move towards sustainable practices and eco-friendly materials, CNC becomes an ideal choice. Its natural origins and minimal environmental impact resonate well with modern consumer preferences for safer and greener products.

Another application of colloidal nano calcium carbonate is in the plastic and polymer industry, where it is used to improve the mechanical properties of materials. The incorporation of CNC can enhance the strength and rigidity of plastics, making them more durable while also reducing the overall weight—a crucial factor in many applications, including automotive and aerospace.

In summary, colloidal nano calcium carbonate stands out as a multifunctional material with diverse applications across various industries. Its unique properties, such as high surface area, low toxicity, and excellent dispersion capabilities, make it a valuable ingredient in the formulation of paints, dyes, and plastics. As research continues to uncover further benefits and applications of CNC, its role in the chemical sector is likely to expand, paving the way for innovative solutions and improved product performance. Understanding the potential of colloidal nano calcium carbonate is essential for anyone involved in the pigments and dyes industry, as it represents a significant advancement in material technology.

best colloidal nano calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.