23

2025

-

07

Why Choose Quality Ultrafine Nano Calcium Carbonate for Advanced Coating Solutions?

Why Choose Quality Ultrafine Nano Calcium Carbonate for Advanced Coating Solutions? Table of Contents 1. Introduction to Ultrafine Nano Calcium Carbonate 2. Key Properties of Ultrafine Nano Calcium Carbonate 2.1. Particle Size and Distribution 2.2. Purity and Chemical Composition 2.3. Surface Area and Reactivity 3. Applications in

Why Choose Quality Ultrafine Nano Calcium Carbonate for Advanced Coating Solutions?

Table of Contents

- 1. Introduction to Ultrafine Nano Calcium Carbonate

- 2. Key Properties of Ultrafine Nano Calcium Carbonate

- 2.1. Particle Size and Distribution

- 2.2. Purity and Chemical Composition

- 2.3. Surface Area and Reactivity

- 3. Applications in Coatings

- 4. Advantages of Using Quality Ultrafine Nano Calcium Carbonate

- 5. Comparing Nano Calcium Carbonate with Other Fillers

- 6. Importance of Choosing the Right Supplier

- 7. Future Trends in Coating Solutions

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Ultrafine Nano Calcium Carbonate

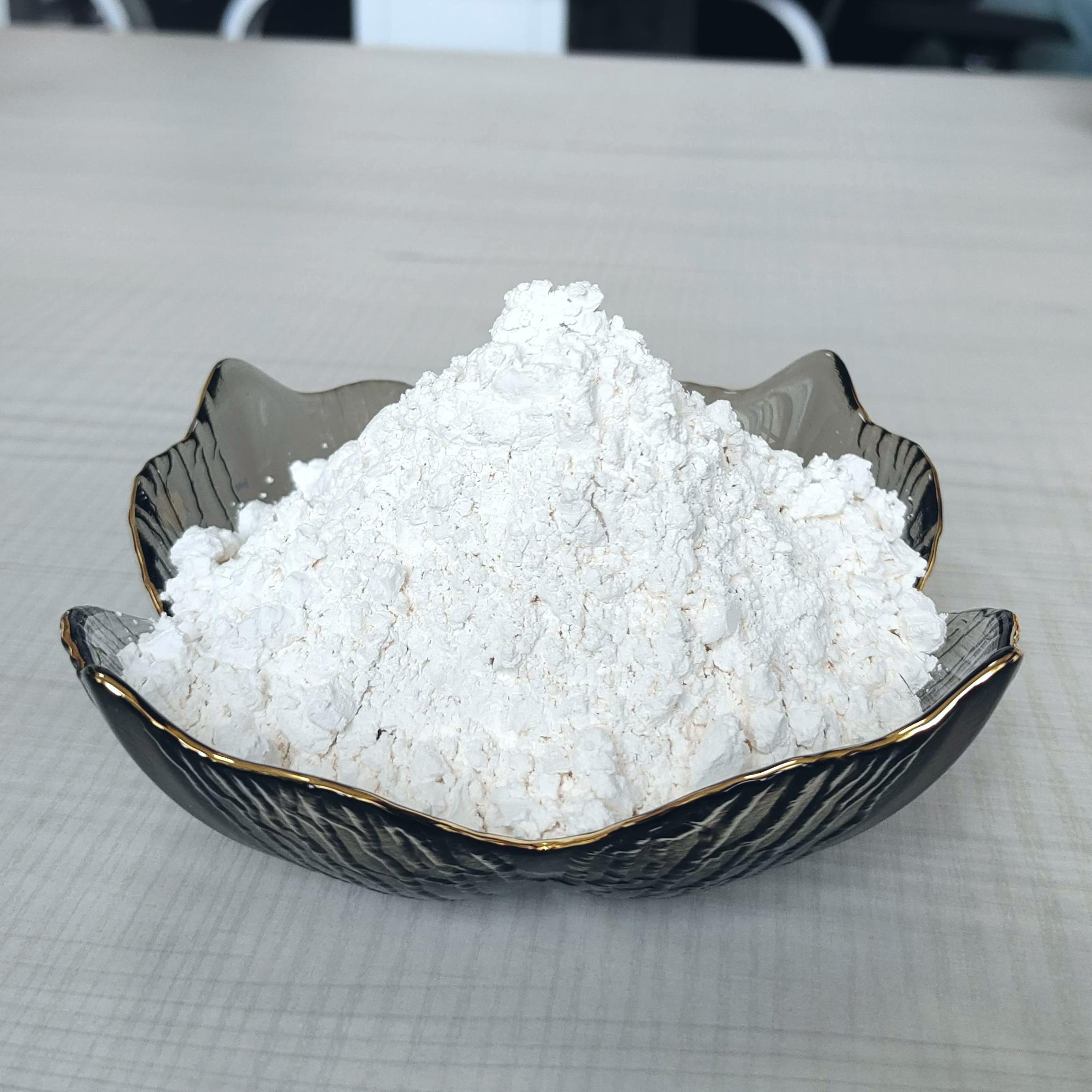

Ultrafine nano calcium carbonate (UCC) is a revolutionary material in the chemical industry, known for its exceptional properties and versatility. It is produced through specialized processes that reduce the particle size to the nanoscale, allowing for a range of unique applications. In the coatings sector, quality UCC is instrumental in enhancing the performance and aesthetic properties of various products.

This article will delve into the reasons why quality ultrafine nano calcium carbonate is the ideal choice for advanced coating solutions, exploring its properties, applications, and advantages in depth.

2. Key Properties of Ultrafine Nano Calcium Carbonate

Understanding the properties of ultrafine nano calcium carbonate is critical in recognizing its value in coating applications. Below are some of the defining characteristics that make it stand out.

2.1. Particle Size and Distribution

One of the most significant attributes of ultrafine nano calcium carbonate is its incredibly small particle size, typically ranging from 1 to 100 nanometers. This small size enhances the material's surface area, allowing for improved interactions with other substances in coatings. The uniformity in particle size distribution ensures consistent performance and optimal results across diverse applications.

2.2. Purity and Chemical Composition

Quality ultrafine nano calcium carbonate boasts high purity levels, often exceeding 99%. This high degree of purity minimizes the risk of contaminants that could negatively impact the performance of coatings. Its chemical composition primarily consists of calcium carbonate (CaCO3), which is non-toxic and environmentally friendly, making it an attractive choice for various applications.

2.3. Surface Area and Reactivity

The large surface area of ultrafine nano calcium carbonate not only enhances its reactivity but also allows for better dispersion in coatings. This improved dispersion leads to enhanced mechanical properties, including increased strength and durability. The reactivity facilitates chemical interactions with polymers and other additives, resulting in superior coating formulations.

3. Applications in Coatings

Ultrafine nano calcium carbonate's unique properties allow it to be utilized in a wide range of coating applications, each benefiting from its remarkable characteristics.

3.1. Aesthetic Qualities

In decorative coatings, ultrafine nano calcium carbonate is often used to improve aesthetic qualities such as gloss and opacity. The fine particles scatter light effectively, providing a bright white finish that enhances color vibrancy. This property is particularly crucial in industries where visual appeal is paramount, such as in automotive and architectural coatings.

3.2. Durability and Protection

Beyond aesthetics, ultrafine nano calcium carbonate significantly enhances the durability of coatings. It acts as a reinforcement agent, improving the mechanical strength of the final product. This increased strength translates to better resistance against wear, impact, and environmental factors, making UCC a desirable choice for exterior coatings, where durability is essential.

3.3. Eco-Friendly Options

As industries increasingly prioritize sustainability, ultrafine nano calcium carbonate presents an eco-friendly alternative to traditional fillers. Its non-toxic nature and ability to reduce the overall material usage in coatings align with modern environmental standards. Utilizing UCC can help companies meet regulatory requirements while enhancing product performance.

4. Advantages of Using Quality Ultrafine Nano Calcium Carbonate

Quality ultrafine nano calcium carbonate offers several advantages that make it a standout choice for manufacturers.

Firstly, its high purity and fine particle size contribute to superior product performance. This means coatings with UCC exhibit enhanced mechanical properties, improved gloss, and better durability.

Secondly, UCC is versatile and can be used across different types of coatings, including water-based, solvent-based, and powder coatings. Its compatibility with various resins allows for flexible formulation options.

Lastly, the eco-friendly nature of ultrafine nano calcium carbonate positions it as a forward-thinking choice for companies seeking to enhance their sustainability profile while maintaining high-quality standards.

5. Comparing Nano Calcium Carbonate with Other Fillers

When evaluating materials for coatings, it’s essential to compare ultrafine nano calcium carbonate with other traditional fillers.

Compared to conventional fillers like talc or kaolin, UCC offers superior mechanical strength and finer particle size. While talc may provide some advantages in terms of cost, it often lacks the same level of performance enhancements seen with UCC.

Moreover, UCC's eco-friendly profile is a significant advantage over synthetic fillers, which may contain harmful substances. This environmental consideration is increasingly important in today’s market.

6. Importance of Choosing the Right Supplier

The quality of ultrafine nano calcium carbonate is heavily influenced by the supplier's manufacturing processes and quality control measures. Choosing a reputable supplier ensures that the UCC meets stringent quality standards, providing the desired performance in coatings.

We recommend looking for suppliers who provide detailed product specifications, including particle size distribution, purity levels, and reactivity data. Additionally, suppliers should be able to demonstrate their commitment to sustainability and environmental responsibility.

7. Future Trends in Coating Solutions

The coatings industry is continually evolving, with a growing focus on innovation and sustainability. Future trends indicate an increasing demand for low-VOC (Volatile Organic Compounds) and environmentally friendly coatings. Ultrafine nano calcium carbonate fits perfectly into this trend, offering a non-toxic alternative that enhances performance without compromising environmental standards.

Furthermore, advancements in nanotechnology are likely to lead to even more innovative applications for ultrafine nano calcium carbonate, expanding its role in the coatings market.

8. Frequently Asked Questions (FAQs)

1. What is ultrafine nano calcium carbonate?

Ultrafine nano calcium carbonate is a refined form of calcium carbonate with particle sizes in the nanometer range. It is widely used in advanced coating solutions due to its excellent properties.

2. How does ultrafine nano calcium carbonate improve coating performance?

UCC enhances coating performance by providing superior mechanical strength, improved gloss, better dispersion, and environmental friendliness.

3. Can ultrafine nano calcium carbonate be used in all types of coatings?

Yes, ultrafine nano calcium carbonate is compatible with various coatings, including water-based, solvent-based, and powder coatings.

4. Is ultrafine nano calcium carbonate eco-friendly?

Yes, UCC is non-toxic and helps reduce material usage in coatings, making it an environmentally friendly choice.

5. How should I choose a supplier for ultrafine nano calcium carbonate?

Look for suppliers with a strong reputation, strict quality control measures, and a commitment to sustainability. It's also beneficial to request detailed product specifications.

9. Conclusion

In conclusion, quality ultrafine nano calcium carbonate is an indispensable component in advanced coating solutions. Its unique properties, including fine particle size, high purity, and eco-friendliness, make it an optimal choice for manufacturers seeking to enhance product performance and aesthetic appeal. By understanding the benefits and applications of UCC, industries can make informed decisions that lead to superior coatings and sustainable practices. As the coatings market continues to evolve, the role of ultrafine nano calcium carbonate will undoubtedly expand, solidifying its position as a critical material in the chemical industry.

quality ultrafine nano calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.