29

2025

-

06

Why Customized High-Whiteness Calcium Carbonate is Essential for Pigment Quality

Why Customized High-Whiteness Calcium Carbonate is Essential for Pigment Quality Table of Contents 1. Introduction 2. What is High-Whiteness Calcium Carbonate? 3. The Importance of Whiteness in Pigments 4. Benefits of Customized High-Whiteness Calcium Carbonate 5. Applications in the Pigment Industry 6. How High-Whiteness Calcium Carbonate Improves Pigment Quality 7. Sourcing an

Why Customized High-Whiteness Calcium Carbonate is Essential for Pigment Quality

Table of Contents

- 1. Introduction

- 2. What is High-Whiteness Calcium Carbonate?

- 3. The Importance of Whiteness in Pigments

- 4. Benefits of Customized High-Whiteness Calcium Carbonate

- 5. Applications in the Pigment Industry

- 6. How High-Whiteness Calcium Carbonate Improves Pigment Quality

- 7. Sourcing and Manufacturing of Customized Calcium Carbonate

- 8. The Future of Calcium Carbonate in Pigment Applications

- 9. Conclusion

- 10. FAQs

1. Introduction

In the world of pigments and dyes, the quest for superior quality is relentless. One of the unsung heroes in achieving this quality is **customized high-whiteness calcium carbonate**. As industries demand greater opacity, brightness, and consistent performance in their pigments, this versatile mineral emerges as a fundamental component. Understanding the significance of customized high-whiteness calcium carbonate can provide manufacturers with a competitive edge, enhancing product quality and meeting rigorous industry standards.

2. What is High-Whiteness Calcium Carbonate?

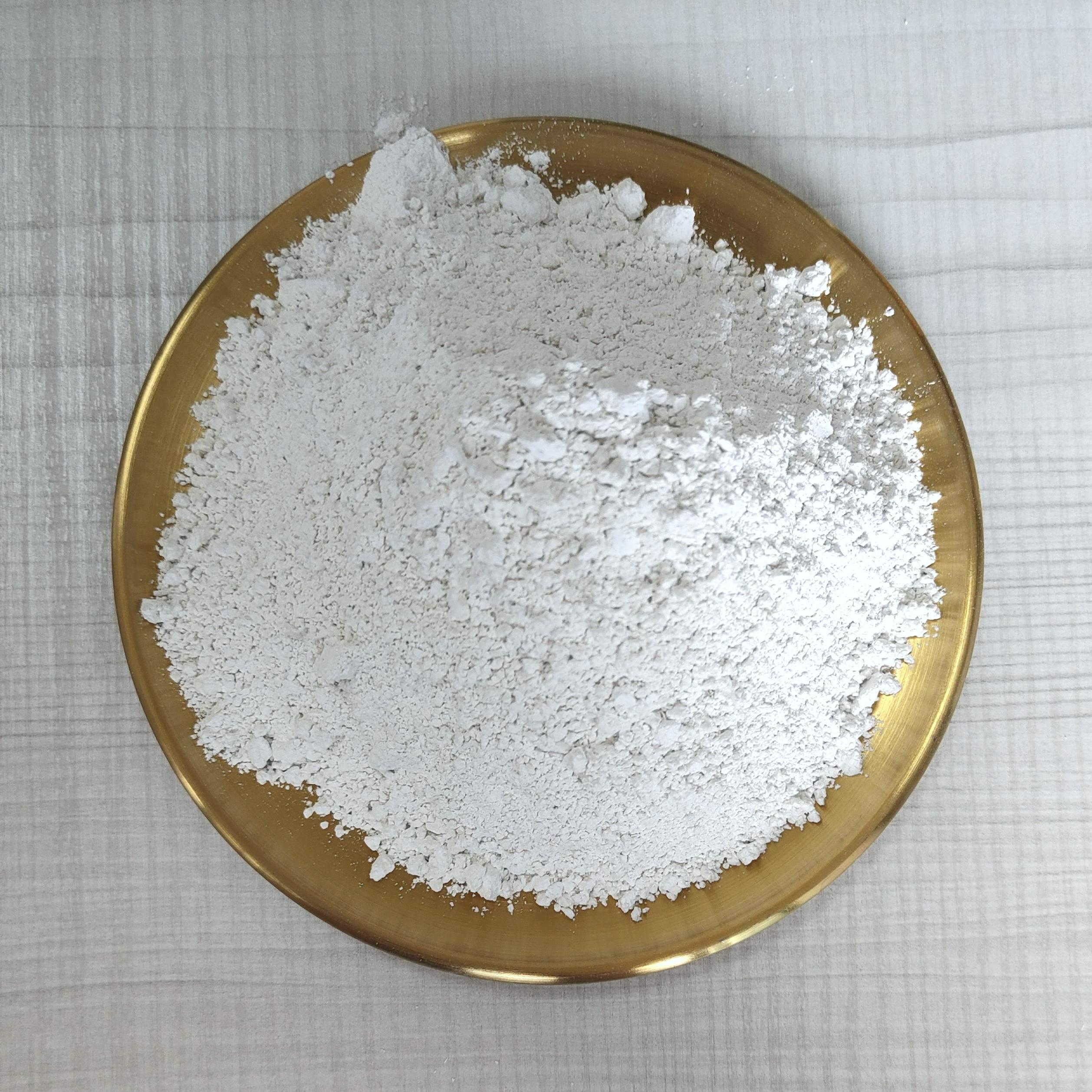

High-whiteness calcium carbonate is a finely-ground mineral derived from limestone or marble, processed to achieve an exceptional level of brightness and purity. Its whiteness is typically measured by the Light Scattering Coefficient (LSC), with customized formulations targeting specific applications in various industries, notably pigments and coatings. This customized approach ensures that manufacturers can tailor the calcium carbonate to meet precise requirements, maximizing its benefits and applications.

3. The Importance of Whiteness in Pigments

Whiteness is not merely a cosmetic attribute; it plays a crucial role in performance. In the pigment industry, high whiteness translates to better coverage, opacity, and brightness. It enhances the visual appeal of products, making them more attractive to consumers. Furthermore, pigments with higher whiteness are often associated with greater durability and stability, making them ideal for applications in paints, plastics, and inks. Thus, manufacturers must prioritize this characteristic to ensure their products stand out in a competitive marketplace.

4. Benefits of Customized High-Whiteness Calcium Carbonate

The advantages of using customized high-whiteness calcium carbonate are manifold:

4.1 Enhanced Opacity and Brightness

Custom formulations can significantly improve the opacity and brightness of pigments, allowing manufacturers to produce vibrant and striking colors.

4.2 Consistency in Quality

Customized calcium carbonate ensures uniformity in particle size and distribution, leading to consistent results in pigment formulations. This consistency is vital for maintaining quality across batches.

4.3 Improved Dispersion and Stability

High-whiteness calcium carbonate offers excellent dispersion properties, aiding in the stability of pigment formulations. This stability translates to longer-lasting products that perform well over time.

4.4 Cost-Effectiveness

By optimizing the formulation of calcium carbonate, manufacturers can reduce the amount of pigment needed while maintaining high quality, leading to cost savings in production.

5. Applications in the Pigment Industry

Customized high-whiteness calcium carbonate finds its place in numerous applications across the pigment industry:

5.1 Paints and Coatings

In paints and coatings, high-whiteness calcium carbonate is used as a filler and pigment extender, improving opacity and overall visual quality.

5.2 Plastics

In the plastics sector, it enhances the mechanical properties of materials while providing whiteness and opacity essential for consumer products.

5.3 Inks

In ink formulations, it contributes to color brightness and consistency, making prints more vivid and appealing.

6. How High-Whiteness Calcium Carbonate Improves Pigment Quality

The role of high-whiteness calcium carbonate in improving pigment quality can be attributed to several factors:

6.1 Light Reflection and Scattering

Its unique refractive index allows high-whiteness calcium carbonate to reflect and scatter light effectively, enhancing the brightness and vibrancy of pigments.

6.2 Chemical Inertness

The chemical inertness of calcium carbonate ensures that it does not react adversely with other components in pigment formulations, maintaining the integrity of the product.

6.3 Particle Size Optimization

Customized formulations allow for precise control over particle size, optimizing the surface area for better dispersion and performance in various applications.

7. Sourcing and Manufacturing of Customized Calcium Carbonate

The sourcing and manufacturing processes play a critical role in determining the quality of customized high-whiteness calcium carbonate. Key considerations include:

7.1 Quality of Raw Materials

The purity and quality of limestone or marble used as raw materials significantly affect the final product's whiteness and performance.

7.2 Advanced Processing Techniques

Utilizing advanced grinding and classification technologies enables manufacturers to achieve the desired particle size and distribution, enhancing the overall quality of calcium carbonate.

7.3 Strict Quality Control Measures

Implementing stringent quality control measures throughout the manufacturing process is essential to ensure that the final product meets industry specifications and customer expectations.

8. The Future of Calcium Carbonate in Pigment Applications

As the demand for high-performance pigments continues to grow, the role of customized high-whiteness calcium carbonate is likely to expand. Innovations in formulation, processing techniques, and applications will drive its evolution, making it a pivotal component in various industries. Companies that invest in research and development will likely stay ahead of the competition, offering enhanced products that meet the needs of an increasingly discerning market.

9. Conclusion

Customized high-whiteness calcium carbonate stands as a cornerstone in the quest for superior pigment quality. Its ability to enhance opacity, brightness, and consistency makes it indispensable in the pigment industry. By investing in customized solutions, manufacturers can not only improve their product offerings but also gain a competitive advantage in a rapidly evolving market. Embracing the benefits of high-whiteness calcium carbonate is essential for those looking to elevate their pigment formulations and meet the demands of today’s consumers.

10. FAQs

1. What is the main benefit of using high-whiteness calcium carbonate in pigments?

The primary benefit is enhanced opacity and brightness, leading to more vibrant and visually appealing products.

2. How does customized calcium carbonate improve pigment stability?

Customized calcium carbonate offers excellent dispersion properties, ensuring that pigments remain stable and consistent over time.

3. Can high-whiteness calcium carbonate be used in environmentally friendly products?

Yes, many formulations of high-whiteness calcium carbonate are eco-friendly and can be utilized in sustainable product lines.

4. What industries utilize high-whiteness calcium carbonate?

It is widely used in industries such as paints, coatings, plastics, and inks.

5. How can manufacturers source high-quality customized calcium carbonate?

Manufacturers should seek suppliers with rigorous quality control measures, advanced processing technologies, and a commitment to using high-quality raw materials.

customized high-whiteness calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.