02

2025

-

07

The Rise of Ultrafine Calcium Carbonate Manufacturers: Innovations and Applications

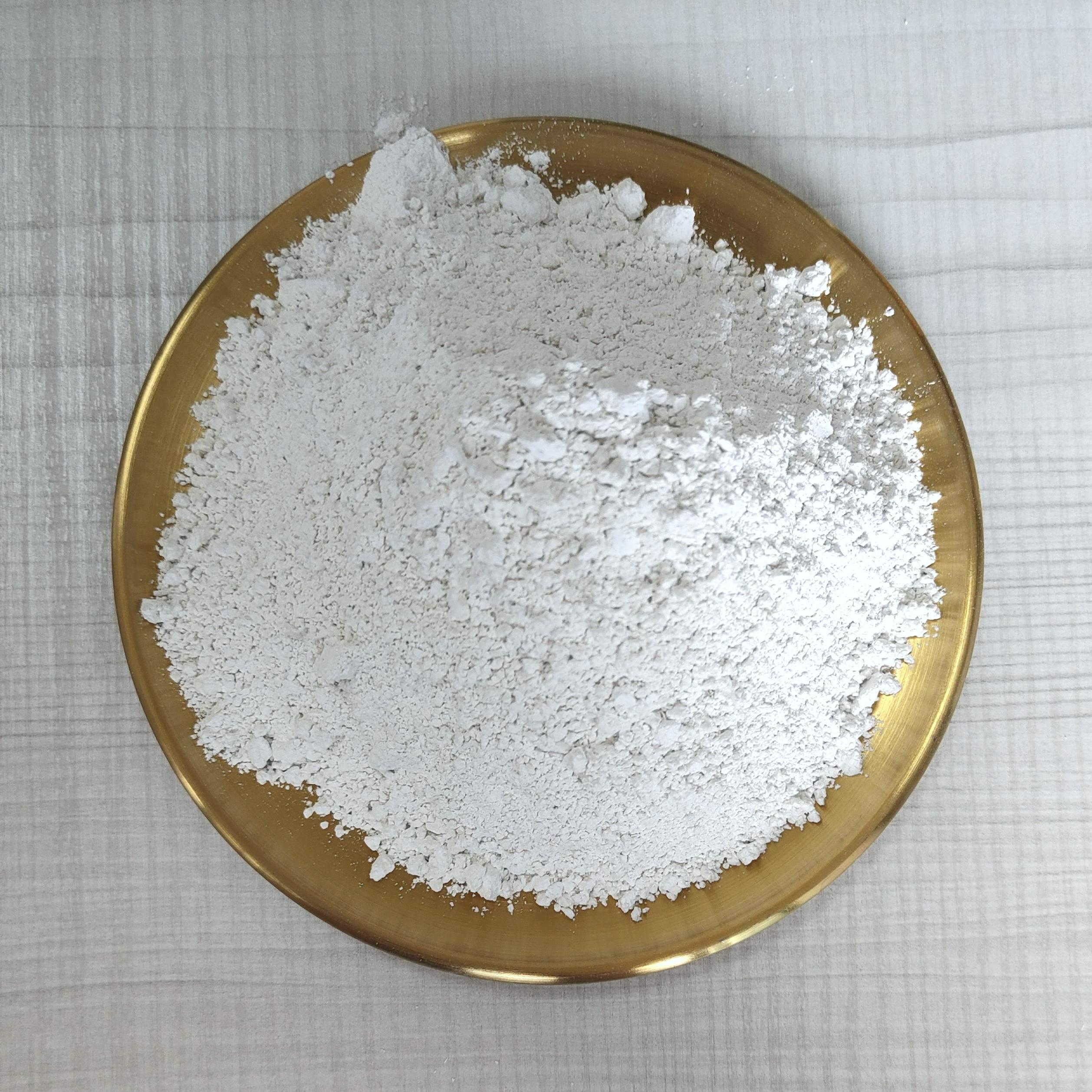

Ultrafine calcium carbonate (UCC) has garnered substantial interest in various industries, particularly in the realm of chemical applications such as pigments and dyes. The unique properties of UCC, including its fineness and purity, make it an essential component in many formulations, contributing to enhanced performance and functionality. Manufacturers of ultrafine calcium carbonate are continua

Manufacturers of ultrafine calcium carbonate are continually innovating to meet the growing demands for high-quality materials. UCC is produced through a process that involves the grinding and classification of natural calcium carbonate to achieve extremely fine particle sizes, often below 2 microns. This fine grading significantly impacts the material’s surface area and reactivity, making it suitable for a variety of applications, including plastics, rubber, paper, paints, and coatings.

One of the primary advantages of using ultrafine calcium carbonate is its ability to improve the mechanical properties of products. For instance, in the coatings industry, UCC can enhance the opacity, brightness, and smoothness of paints, resulting in a superior finish. Additionally, its fine particle size allows for better dispersion in liquid formulations, which is crucial for achieving consistent quality in the final product.

In the plastics sector, ultrafine calcium carbonate is utilized as a cost-effective filler that not only lowers production costs but also improves the stiffness and impact resistance of plastic materials. This dual benefit of performance enhancement and cost reduction makes UCC a preferred choice among manufacturers.

Moreover, the environmental considerations associated with ultrafine calcium carbonate manufacturing cannot be overlooked. Many manufacturers are adopting sustainable practices by utilizing natural resources and minimizing waste. The rising trend of eco-friendly products has prompted companies to focus on producing UCC with a lower environmental footprint, aligning with global sustainability goals.

As the demand for ultrafine calcium carbonate continues to rise, manufacturers are also exploring alternative sources and innovative processing techniques. This includes the exploration of biogenic calcium carbonate from shellfish or other organic sources, which could pave the way for more sustainable production methods.

In summary, ultrafine calcium carbonate manufacturers play a pivotal role in the evolution of materials used across various industries. By focusing on innovation, sustainability, and quality, these manufacturers are not only meeting the immediate demands of the market but also setting the stage for future advancements. As industries continue to evolve, the role of UCC in enhancing product performance while addressing environmental concerns will surely expand, making it an exciting area for ongoing developments and research.

ultrafine calcium carbonate manufacturers

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.