11

2025

-

07

The Science Behind High-Whiteness Calcium Carbonate: Your Ultimate Guide to Applications and Benefits

The Science Behind High-Whiteness Calcium Carbonate: Your Ultimate Guide to Applications and Benefits High-whiteness calcium carbonate is a vital component in several industries, encompassing paint, plastics, paper, and more. It provides not only a brilliant white color but also enhances performance characteristics. In this article, we will explore the science behind high-whiteness calcium carbona

The Science Behind High-Whiteness Calcium Carbonate: Your Ultimate Guide to Applications and Benefits

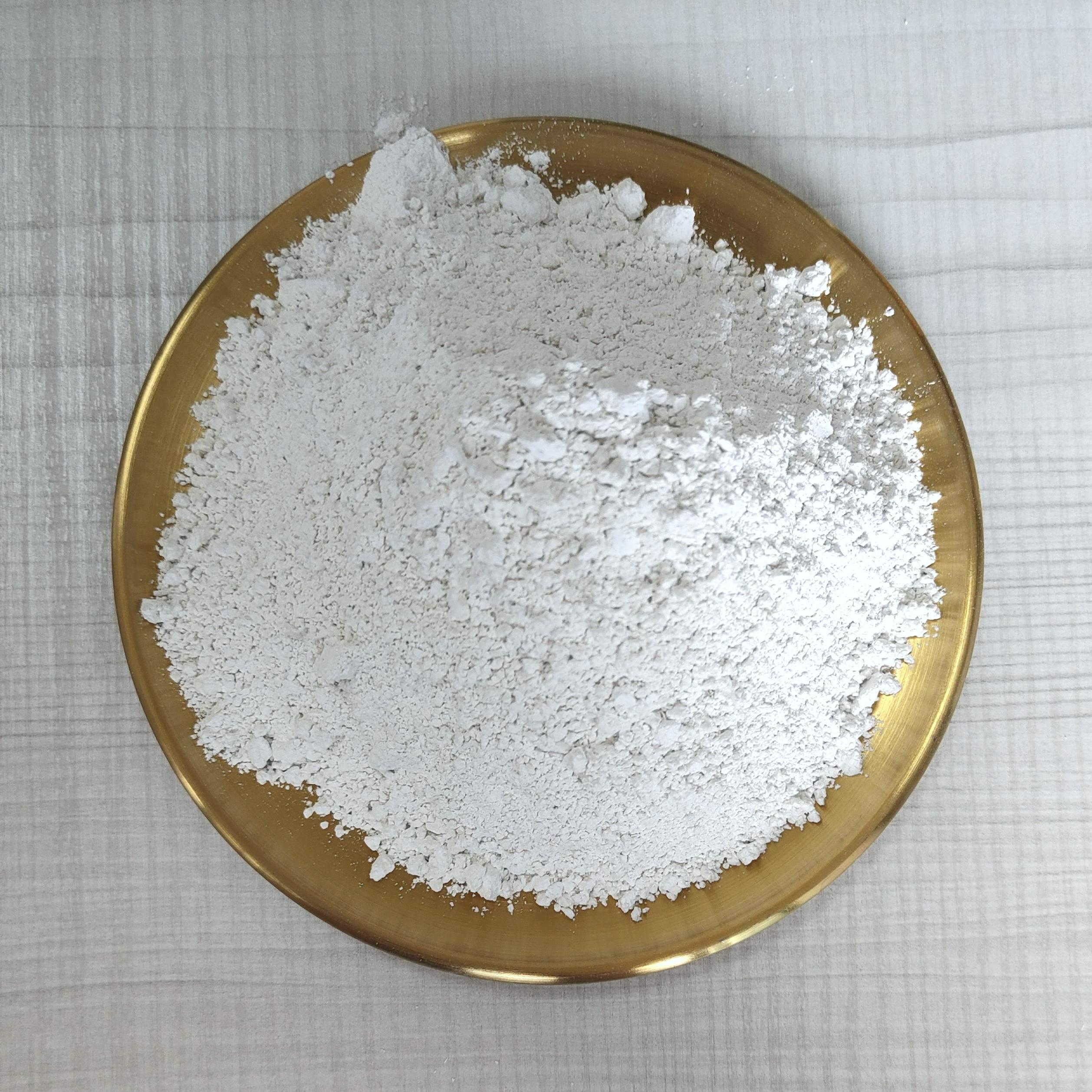

High-whiteness calcium carbonate is a vital component in several industries, encompassing paint, plastics, paper, and more. It provides not only a brilliant white color but also enhances performance characteristics. In this article, we will explore the science behind high-whiteness calcium carbonate, its production methods, applications, benefits, and much more.

Table of Contents

- Understanding Calcium Carbonate

- Properties of High-Whiteness Calcium Carbonate

- The Production Process of High-Whiteness Calcium Carbonate

- Applications in Various Industries

- Benefits of Using High-Whiteness Calcium Carbonate

- Comparison to Other Pigments

- Environmental Impact and Sustainability

- Future Trends in Calcium Carbonate Usage

- Frequently Asked Questions

- Conclusion

Understanding Calcium Carbonate

Calcium carbonate (CaCO3) is a naturally occurring mineral that is abundant in the Earth's crust. It is found in various forms, such as chalk, limestone, and marble. The versatility of calcium carbonate makes it a pivotal material in numerous applications, primarily due to its chemical stability, non-toxicity, and affordability.

Types of Calcium Carbonate

Calcium carbonate can be classified into two primary forms: ground calcium carbonate (GCC) and precipitated calcium carbonate (PCC). GCC is produced by grinding limestone or marble, while PCC is manufactured through a chemical process that involves dissolving calcium oxide in water.

Properties of High-Whiteness Calcium Carbonate

The term "high-whiteness" refers to the exceptional brightness and color quality of the calcium carbonate used. This property is critical for its performance in applications where color consistency is essential.

Measuring Whiteness

Whiteness is often quantified using the Hunter Lab Scale and other similar metrics. A high-whiteness calcium carbonate typically scores above 95 on this scale, making it suitable for demanding applications.

Key Physical Properties

- Particle Size Distribution: Fine particle size enhances the opacity and brightness.

- Brightness: High whiteness contributes to superior reflectivity, making it an ideal choice for coatings and plastics.

- Chemical Purity: A low level of impurities ensures consistency in performance across applications.

The Production Process of High-Whiteness Calcium Carbonate

The production of high-whiteness calcium carbonate involves several steps designed to enhance its purity and whiteness. Understanding this process is crucial for manufacturers who wish to ensure quality control in their products.

Extraction and Processing

The initial step involves the extraction of limestone from quarries. The extracted limestone undergoes crushing and grinding to produce a finer material. Subsequently, it is subjected to various treatments to remove impurities and ensure a high brightness level.

Precipitation Process

For precipitated calcium carbonate, the process begins with the reaction of calcium oxide with water to form calcium hydroxide, followed by carbonation to produce PCC. This method allows for precise control over particle size and purity, resulting in superior whiteness.

Applications in Various Industries

High-whiteness calcium carbonate finds applications in multiple sectors, ranging from construction to pharmaceuticals.

1. Paint and Coatings

In the paint industry, high-whiteness calcium carbonate serves as a pigment and filler. Its superior whiteness enhances the opacity of paints, while its fine particle size contributes to a smoother finish.

2. Plastics

In plastics, high-whiteness calcium carbonate is used as a filler to improve mechanical properties and reduce costs. It enhances the brightness and overall visual appeal of plastic products.

3. Paper Manufacturing

In the paper industry, it acts as a filler that enhances brightness while reducing the need for more expensive pigments. This results in better printability and opacity.

4. Pharmaceuticals

High-whiteness calcium carbonate is utilized in pharmaceuticals as a calcium supplement and as an excipient in tablet formulations.

Benefits of Using High-Whiteness Calcium Carbonate

The benefits of incorporating high-whiteness calcium carbonate into products are numerous and varied.

Cost-Effectiveness

High-whiteness calcium carbonate is more affordable compared to alternative pigments, making it an economical choice for manufacturers looking to reduce production costs.

Improved Product Quality

Its ability to enhance brightness and opacity contributes to the overall quality and aesthetics of final products.

Versatility

This compound's adaptability allows for its use in a wide array of applications, catering to diverse industrial needs.

Comparison to Other Pigments

When comparing high-whiteness calcium carbonate to other common pigments like titanium dioxide, it's essential to consider several factors.

Cost Comparison

While titanium dioxide provides excellent whiteness, it comes at a higher price point. High-whiteness calcium carbonate offers an affordable alternative without compromising on essential properties.

Environmental Considerations

Calcium carbonate is generally more environmentally friendly than synthetic pigments, which may contain harmful chemicals. Its natural origin and non-toxic nature make it a preferable choice in many applications.

Environmental Impact and Sustainability

With increasing awareness about sustainability, the environmental impact of materials is a significant concern. High-whiteness calcium carbonate is sourced from natural deposits, making it a more sustainable option compared to synthetic alternatives.

Recycling and Reusability

Calcium carbonate can be recycled and reused in many applications, supporting a circular economy. This characteristic aligns with modern sustainability goals and reduces waste.

Future Trends in Calcium Carbonate Usage

As industries evolve, the demand for high-whiteness calcium carbonate is expected to grow, driven by innovation in production techniques and evolving applications.

Innovation in Production Techniques

Advancements in technology and production methods will likely enhance the purity and efficiency of high-whiteness calcium carbonate, making it even more appealing to manufacturers.

Emerging Applications

New applications are continually being discovered, from its use in biodegradable materials to the food industry, indicating a bright future for high-whiteness calcium carbonate.

Frequently Asked Questions

1. What is high-whiteness calcium carbonate used for?

High-whiteness calcium carbonate is primarily used in paints, plastics, paper, and pharmaceuticals as a pigment and filler.

2. How does high-whiteness calcium carbonate compare to titanium dioxide?

While titanium dioxide offers superior whiteness, high-whiteness calcium carbonate is more cost-effective and environmentally friendly.

3. Is high-whiteness calcium carbonate safe for use in food products?

Yes, high-whiteness calcium carbonate is non-toxic and is utilized as a food additive in some applications.

4. What factors influence the whiteness of calcium carbonate?

Factors include the purity of the source material, production methods, and particle size distribution.

5. Can calcium carbonate be recycled?

Yes, calcium carbonate can be recycled and reused in various applications, supporting sustainability efforts.

Conclusion

High-whiteness calcium carbonate is not just a pigment; it is a multifunctional material that plays an integral role in various industries. Its unique properties, coupled with cost-effectiveness and environmental benefits, make it a preferred choice for manufacturers worldwide. As technology progresses and new applications emerge, we can expect high-whiteness calcium carbonate to remain a staple in the realm of pigments and fillers.

high-whiteness calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.