05

2025

-

07

How Colloidal Nano Calcium Carbonate Enhances Color Stability in Dyes

How Colloidal Nano Calcium Carbonate Enhances Color Stability in Dyes Introduction to Colloidal Nano Calcium Carbonate In the ever-evolving world of the chemical industry, pigments and dyes play a crucial role in various applications, from textiles to coatings. One of the emerging stars in this realm is colloidal nano calcium carbonate (CNC). This innovative material is not just another additive;

How Colloidal Nano Calcium Carbonate Enhances Color Stability in Dyes

Introduction to Colloidal Nano Calcium Carbonate

In the ever-evolving world of the chemical industry, pigments and dyes play a crucial role in various applications, from textiles to coatings. One of the emerging stars in this realm is colloidal nano calcium carbonate (CNC). This innovative material is not just another additive; it serves as a game-changer in improving color stability in dyes. But what exactly is colloidal nano calcium carbonate, and why is it vital for enhancing color stability?

The Science Behind Colloidal Nano Calcium Carbonate

Understanding Nano Calcium Carbonate

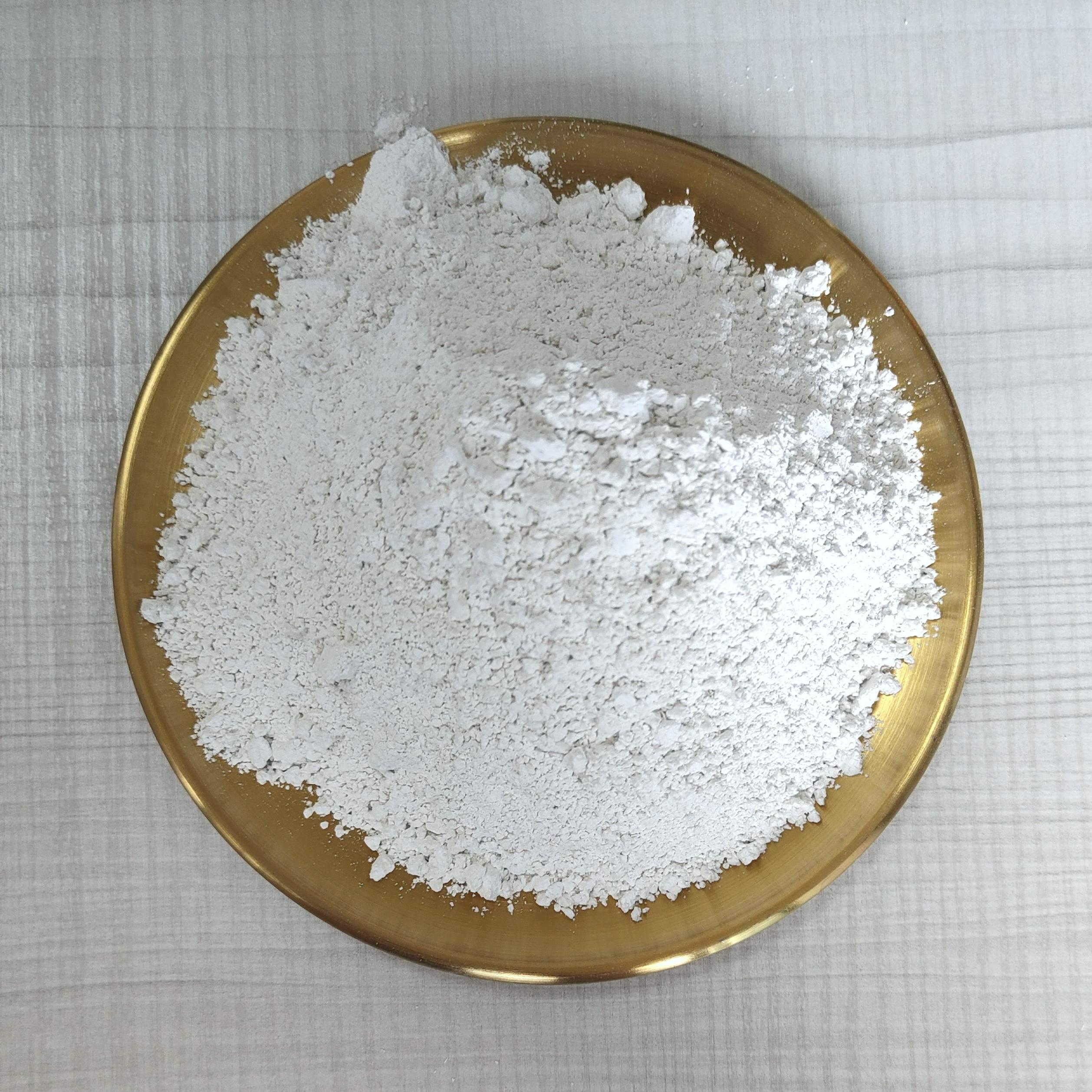

Colloidal nano calcium carbonate refers to ultra-fine particles of calcium carbonate that are suspended in a liquid medium. These particles typically range in size from 1 to 100 nanometers, providing unique properties that bulk calcium carbonate cannot offer. The small size and high surface area of CNC particles lead to remarkable interactions with dyes, making them ideal for improving color stability.

Unique Properties of Colloidal Nano Calcium Carbonate

One of the primary reasons colloidal nano calcium carbonate enhances color stability in dyes is its exceptional surface properties. The high surface area allows for better adsorption of dye molecules. Additionally, CNC has a neutral pH, which means it does not interfere with the dyeing process. Its low density and lightweight nature make it easy to incorporate into various dye formulations without adding significant weight.

Applications of Colloidal Nano Calcium Carbonate in the Dyeing Industry

Textile Dyeing

In the textile industry, color stability is critical. Fabrics that fade quickly lose their appeal and can lead to customer dissatisfaction. By incorporating colloidal nano calcium carbonate into textile dyes, manufacturers can achieve enhanced colorfastness. This means that the vibrant hues of the fabrics remain intact even after exposure to harsh conditions such as sunlight, washing, and abrasion.

Coatings and Paints

The coating industry also benefits significantly from colloidal nano calcium carbonate. Paints that utilize this additive not only exhibit improved color stability but also enhanced opacity and brightness. The CNC particles disperse evenly throughout the paint, preventing settling and ensuring a consistent application. As a result, surfaces painted with such formulations maintain their aesthetic appeal for longer periods.

Cosmetic Dyes

In cosmetics, the vibrancy and longevity of colors are paramount. Colloidal nano calcium carbonate can be employed in various cosmetic formulations, from lipsticks to face powders. By stabilizing the colorants, CNC helps ensure that cosmetic products retain their intended hues throughout their shelf life, providing consumers with reliable, high-quality products.

Mechanisms of Color Stability Enhancement

Improved Adsorption Properties

The small particle size of colloidal nano calcium carbonate allows for increased surface area, leading to enhanced adsorption capabilities. This enables the CNC to hold dye molecules more effectively, reducing the likelihood of color leaching during washing or exposure to environmental factors.

pH Neutral Character

Given its neutral pH, colloidal nano calcium carbonate does not alter the chemical balance of dye formulations. This characteristic is crucial as it ensures that the dyes remain stable and vibrant without the risk of chemical reactions that could lead to color degradation.

Reduction of Light Scattering

The incorporation of CNC into dye formulations can also reduce light scattering. This property enhances the perception of color intensity, making dyes appear more vibrant and true to their original hues. By minimizing light scattering, colloidal nano calcium carbonate contributes to the overall aesthetic quality of the dyed materials.

Challenges and Considerations

Compatibility with Other Additives

While colloidal nano calcium carbonate offers significant advantages, it is essential to consider its compatibility with other additives in dye formulations. Manufacturers must conduct thorough testing to ensure that CNC interacts positively with various dyes, binders, and surfactants.

Cost Implications

As with any advanced material, the cost can be a consideration when incorporating colloidal nano calcium carbonate into dye formulations. However, the benefits of improved color stability and product performance often outweigh the initial investment for manufacturers looking to enhance their offerings.

Future Trends in the Use of Colloidal Nano Calcium Carbonate

As research continues to unveil the potential applications of colloidal nano calcium carbonate, we anticipate further innovations in the dyeing industry. From sustainable practices to new formulations, CNC is likely to play a crucial role in driving advancements in dye technology.

Enhanced Sustainability

The push for more sustainable practices in the chemical industry means that colloidal nano calcium carbonate will likely find its place in eco-friendly dye formulations. Its natural origins and ability to improve product longevity align perfectly with the growing demand for sustainable and environmentally friendly options.

Integration into Smart Textiles

As the textile industry explores the integration of smart technologies, colloidal nano calcium carbonate could be pivotal in creating textiles that not only change color based on environmental stimuli but also maintain their vibrancy over extended periods.

FAQs about Colloidal Nano Calcium Carbonate in Dyes

1. What is colloidal nano calcium carbonate?

Colloidal nano calcium carbonate is a form of calcium carbonate composed of extremely fine particles suspended in a liquid. Its small size and large surface area provide unique properties that enhance dye formulations.

2. How does colloidal nano calcium carbonate enhance color stability?

The high surface area of CNC allows for better adsorption of dye molecules, its neutral pH prevents chemical reactions that could degrade color, and it reduces light scattering, enhancing the vibrancy of dyes.

3. What industries can benefit from using colloidal nano calcium carbonate?

Colloidal nano calcium carbonate is beneficial in various industries, including textile dyeing, coatings and paints, and cosmetics.

4. Are there any challenges in using colloidal nano calcium carbonate?

Yes, compatibility with other additives and cost implications are potential challenges that manufacturers must address when incorporating CNC into dye formulations.

5. What are the future trends for colloidal nano calcium carbonate in dye applications?

Future trends may include enhanced sustainability practices and integration into smart textiles, allowing for innovative applications in the dyeing industry.

Conclusion

In conclusion, colloidal nano calcium carbonate emerges as a powerful ally in the quest for color stability in dyes. Its unique properties, such as improved adsorption, pH neutrality, and reduced light scattering, make it an invaluable addition across various industries, including textiles and cosmetics. As we look to the future, the potential for further innovation with colloidal nano calcium carbonate is immense. Manufacturers who adopt this cutting-edge material can expect to see not only enhanced product quality but also increased customer satisfaction in an ever-competitive market. By integrating colloidal nano calcium carbonate into their formulations, companies can pave the way for a new era of vibrant and enduring color in their products.

colloidal nano calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.