06

2025

-

09

Unlocking the Potential of Coated Calcium Carbonate in Industrial Applications

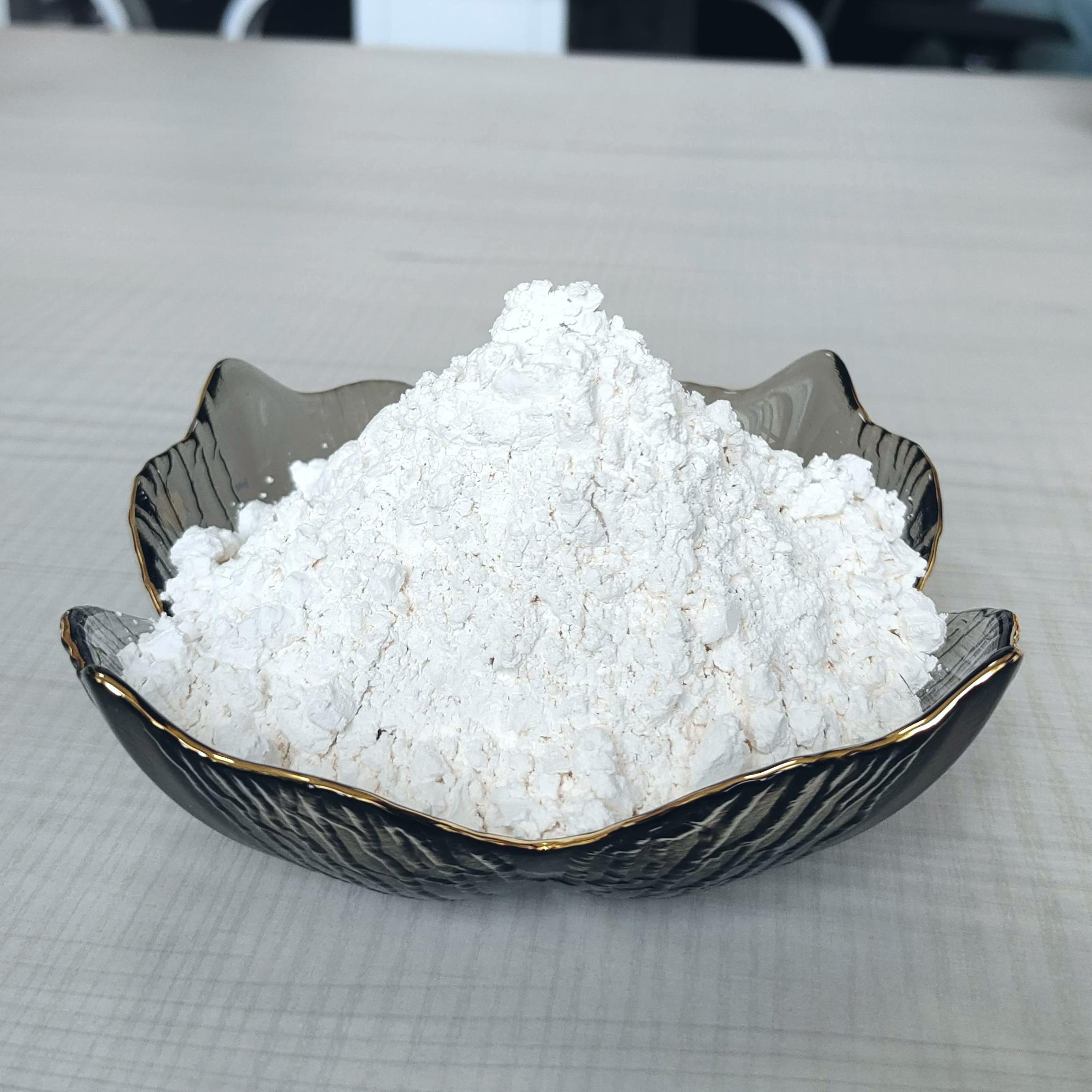

Coated calcium carbonate (CCC) has become increasingly vital in various industrial applications, particularly within the chemical sector. This innovative material is essentially calcium carbonate particles coated with organic or inorganic substances to enhance their properties, making them suitable for a wide range of uses. Its unique characteristics offer significant advantages, particularly in t

One of the primary benefits of coated calcium carbonate is its improved dispersibility. The coating reduces the agglomeration of calcium carbonate particles, allowing for a more uniform distribution in formulations. This uniformity is crucial in applications such as paints, coatings, plastics, and rubber, where consistent quality and performance are paramount. The enhanced dispersibility also leads to better processing characteristics, enabling manufacturers to achieve smoother textures and superior finishes in their end products.

Moreover, the coating can serve to enhance the surface properties of calcium carbonate, such as hydrophobicity or hydrophilicity, depending on the application requirements. For instance, in the plastic industry, modifying the surface properties can improve the compatibility of CCC with various polymers, resulting in improved mechanical strength and thermal stability of the final product. This adaptability makes coated calcium carbonate a versatile additive, tailored to meet the specific needs of different industries.

Another significant advantage of coated calcium carbonate is its ability to act as a functional filler, providing not only bulk but also performance enhancements. In the paper industry, for instance, CCC can improve brightness and opacity, contributing to better print quality and overall aesthetic appeal. In coatings, it helps to enhance opacity and gloss, making it essential for producing high-quality decorative paints.

From an economic perspective, the use of coated calcium carbonate can lead to cost savings through the reduction of raw material requirements, lowering production costs while maintaining product integrity. By substituting more expensive materials with CCC, manufacturers can achieve competitive advantages in pricing while still delivering high-quality products.

Furthermore, environmental considerations play an increasingly important role in industrial processes. Coated calcium carbonate, being derived from natural sources, offers a more sustainable alternative to synthetic fillers. Its use can contribute to reducing the carbon footprint of various products, aligning with global trends toward greener manufacturing practices.

In conclusion, coated calcium carbonate presents a wealth of opportunities for enhancing product performance and efficiency in the chemical industry. Its unique properties make it an essential component across various applications, from coatings to plastics and beyond. By understanding the benefits and potential uses of CCC, professionals in the industry can leverage this material to drive innovation and improve their product offerings. As the market continues to evolve, staying informed about the advancements in coated calcium carbonate will be crucial for maintaining a competitive edge.

coated calcium carbonate

Previous page

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.