11

2025

-

06

Understanding the Manufacturing Process of Ultrafine Nano Calcium Carbonate: A Comprehensive Guide

Understanding the Manufacturing Process of Ultrafine Nano Calcium Carbonate Table of Contents 1. Introduction to Ultrafine Nano Calcium Carbonate 2. Importance of Ultrafine Nano Calcium Carbonate in Modern Industries 3. The Manufacturing Process of Ultrafine Nano Calcium Carbonate 3.1 Raw Materials Used in Production 3.2 Mechanical Methods of Productio

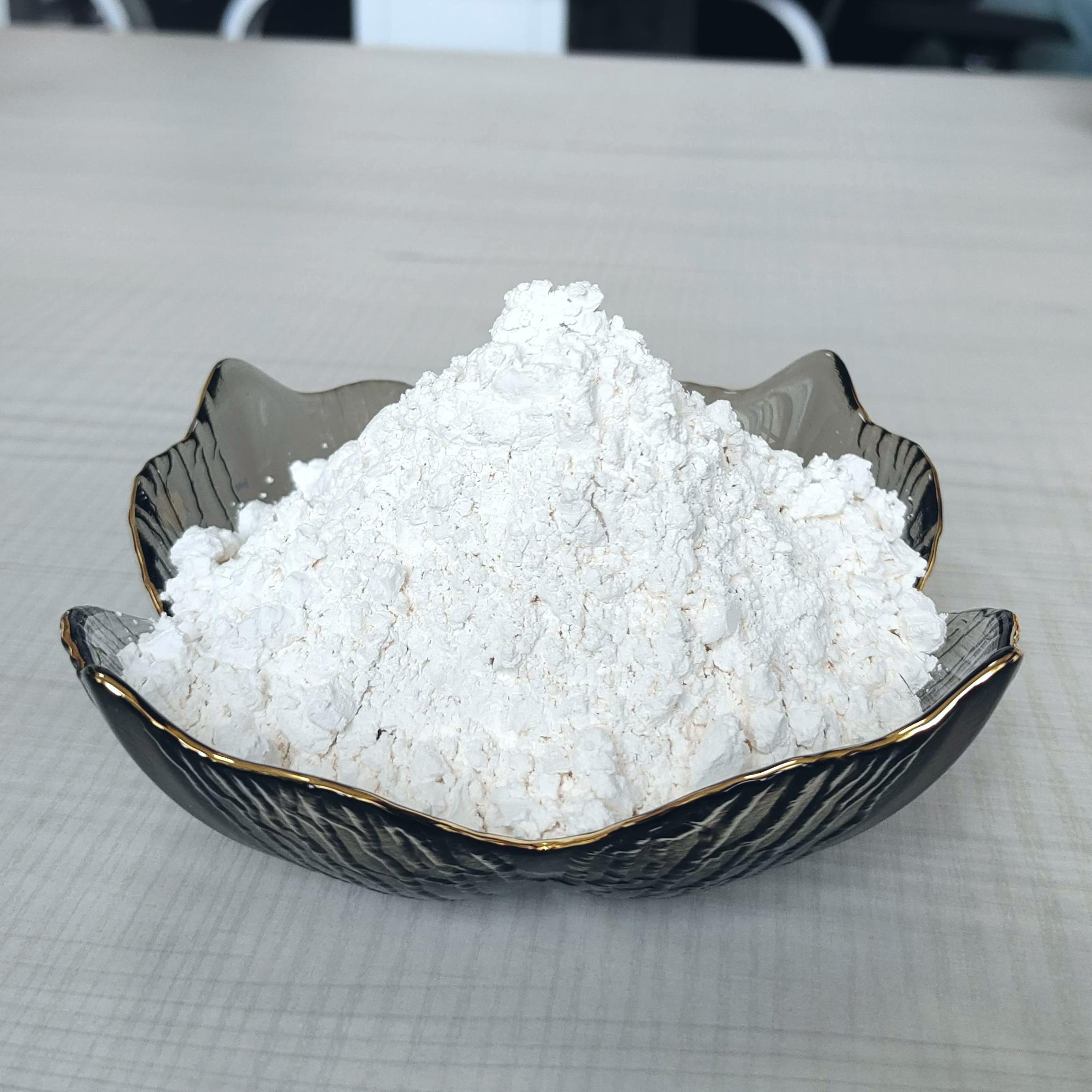

Understanding the Manufacturing Process of Ultrafine Nano Calcium Carbonate

Table of Contents

- 1. Introduction to Ultrafine Nano Calcium Carbonate

- 2. Importance of Ultrafine Nano Calcium Carbonate in Modern Industries

- 3. The Manufacturing Process of Ultrafine Nano Calcium Carbonate

- 3.1 Raw Materials Used in Production

- 3.2 Mechanical Methods of Production

- 3.3 Chemical Methods of Production

- 3.4 Precipitation Method

- 4. Key Characteristics of Ultrafine Nano Calcium Carbonate

- 5. Applications of Ultrafine Nano Calcium Carbonate in Various Industries

- 6. Challenges in the Manufacturing of Ultrafine Nano Calcium Carbonate

- 7. The Future of Ultrafine Nano Calcium Carbonate

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Ultrafine Nano Calcium Carbonate

Ultrafine nano calcium carbonate (NCC) has gained significant attention within the chemical industry due to its unique properties and vast applications. As a versatile mineral filler, NCC serves as an essential component in numerous applications, including paints, coatings, plastics, rubber, and pharmaceuticals. This article seeks to provide a thorough understanding of the manufacturing process of ultrafine nano calcium carbonate, enabling readers to grasp its significance and complexities.

2. Importance of Ultrafine Nano Calcium Carbonate in Modern Industries

The importance of ultrafine nano calcium carbonate in various industries cannot be overstated. Its fine particle size and high specific surface area enhance the performance of materials in which it is incorporated. NCC is praised for its ability to improve mechanical strength, reduce production costs, and enhance the transparency of coatings and plastics. Furthermore, its non-toxic nature makes it an attractive option for applications in food, pharmaceuticals, and cosmetics.

3. The Manufacturing Process of Ultrafine Nano Calcium Carbonate

The production of ultrafine nano calcium carbonate involves several sophisticated methods that cater to the desired particle size, morphology, and purity level. Understanding these methods is crucial for optimizing the manufacturing process and ensuring the quality of the final product.

3.1 Raw Materials Used in Production

The primary raw material for producing ultrafine nano calcium carbonate is naturally occurring limestone, which is predominantly composed of calcium carbonate (CaCO3). High-purity limestone is essential to ensure that the final product is free of impurities that could affect its performance. Additionally, other chemicals such as carbon dioxide (CO2) and water are often used in the production process.

3.2 Mechanical Methods of Production

Mechanical milling techniques are commonly employed to produce ultrafine calcium carbonate. These methods involve grinding limestone into finer particles using various types of mills such as ball mills, jet mills, or impact mills. The mechanical milling process can effectively reduce particle size but often results in a broader particle size distribution.

3.3 Chemical Methods of Production

Chemical methods used for producing ultrafine nano calcium carbonate typically involve precipitation reactions. This process entails dissolving calcium salts in water, followed by the introduction of CO2 gas, which precipitates calcium carbonate. This method allows for better control over the particle size and morphology of the final product.

3.4 Precipitation Method

The precipitation method is a popular choice for manufacturing ultrafine nano calcium carbonate. This process involves the following steps:

1. **Dissolution**: Calcium oxide (CaO) is dissolved in water to produce calcium hydroxide (Ca(OH)2).

2. **Carbonation**: CO2 gas is bubbled into the calcium hydroxide solution, leading to the formation of calcium carbonate precipitate.

3. **Separation**: The formed calcium carbonate is separated from the liquid phase through filtration, centrifugation, or sedimentation.

4. **Washing and Drying**: The precipitate is washed to remove impurities and then dried to achieve the desired moisture content.

This method allows for the production of highly pure ultrafine nano calcium carbonate with controlled particle size and morphology.

4. Key Characteristics of Ultrafine Nano Calcium Carbonate

Ultrafine nano calcium carbonate possesses several key characteristics that distinguish it from conventional calcium carbonate. These characteristics include:

- **Small Particle Size**: Typically ranging from 1 to 100 nanometers, ultrafine NCC exhibits a high specific surface area, which enhances its reactivity and performance in various applications.

- **High Purity**: The chemical properties of nano calcium carbonate are crucial for ensuring the desired performance in end-use applications, making purity a significant consideration during manufacturing.

- **Surface Modifications**: The surface of ultrafine NCC can be modified to enhance compatibility with various polymers and other materials, making it versatile for multiple applications.

5. Applications of Ultrafine Nano Calcium Carbonate in Various Industries

Ultrafine nano calcium carbonate finds applications across a broad spectrum of industries:

- **Paints and Coatings**: It serves as a pigment and filler, enhancing the opacity, brightness, and durability of paints and coatings.

- **Plastics**: Used as a reinforcing agent, it improves the mechanical properties, thermal stability, and processing characteristics of plastic materials.

- **Rubber**: In rubber manufacturing, NCC acts as a filler that enhances strength and reduces production costs.

- **Pharmaceuticals**: Its non-toxic nature makes it suitable as an excipient in drug formulations, helping to improve the flow properties and compressibility of powders.

- **Food Industry**: In food applications, NCC is used as an anti-caking agent and a bulking agent due to its safety profile.

6. Challenges in the Manufacturing of Ultrafine Nano Calcium Carbonate

Despite the numerous advantages, the manufacturing process of ultrafine nano calcium carbonate faces several challenges:

- **Control of Particle Size**: Achieving a consistent and narrow particle size distribution is crucial for ensuring performance consistency across applications.

- **Purity Maintenance**: Maintaining high purity levels is essential to avoid contamination that could hinder the performance of NCC in sensitive applications.

- **Cost of Production**: The production methods employed can be costly, particularly when high purity and fine particle size are required.

7. The Future of Ultrafine Nano Calcium Carbonate

The future of ultrafine nano calcium carbonate is promising, with ongoing research focused on enhancing its properties and applications. As industries increasingly seek sustainable and high-performance materials, the demand for NCC is expected to grow. Innovations in production techniques and surface modifications will further optimize its performance in various applications, paving the way for new market opportunities.

8. Frequently Asked Questions

What is ultrafine nano calcium carbonate?

Ultrafine nano calcium carbonate is a fine particulate form of calcium carbonate, characterized by its small particle size (1-100 nanometers) and high specific surface area.

What are the main applications of ultrafine nano calcium carbonate?

NCC is widely used in paints, coatings, plastics, rubber, pharmaceuticals, and food industries, serving as a filler, pigment, and functional additive.

How is ultrafine nano calcium carbonate produced?

It can be produced using mechanical milling or chemical methods such as precipitation, where calcium salts react with CO2 to form calcium carbonate.

What are the benefits of using ultrafine nano calcium carbonate in products?

NCC enhances mechanical strength, reduces production costs, improves opacity, and provides better flow properties in various materials.

What challenges are associated with manufacturing ultrafine nano calcium carbonate?

Key challenges include maintaining consistent particle size distribution, ensuring high purity, and managing production costs.

9. Conclusion

In conclusion, ultrafine nano calcium carbonate is a vital material in various industries, thanks to its unique characteristics and benefits. Understanding the intricacies of its manufacturing process is essential for optimizing its production and ensuring high-quality outcomes. As demand for sustainable, high-performance materials continues to rise, ultrafine NCC is poised to play an increasingly important role in meeting the needs of modern industries. By addressing the challenges in its production and leveraging advancements in technology, we can unlock the full potential of ultrafine nano calcium carbonate for future applications.

ultrafine nano calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.