18

2025

-

05

Exploring the Role of High-Whiteness Calcium Carbonate in Pigment Production

Exploring the Role of High-Whiteness Calcium Carbonate in Pigment Production In the world of pigment production, the quest for superior quality, brightness, and opacity is a constant endeavor. One material that has gained significant attention in this domain is high-whiteness calcium carbonate (CaCO3). This versatile mineral not only acts as a functional filler but also plays a crucial role in imp

Exploring the Role of High-Whiteness Calcium Carbonate in Pigment Production

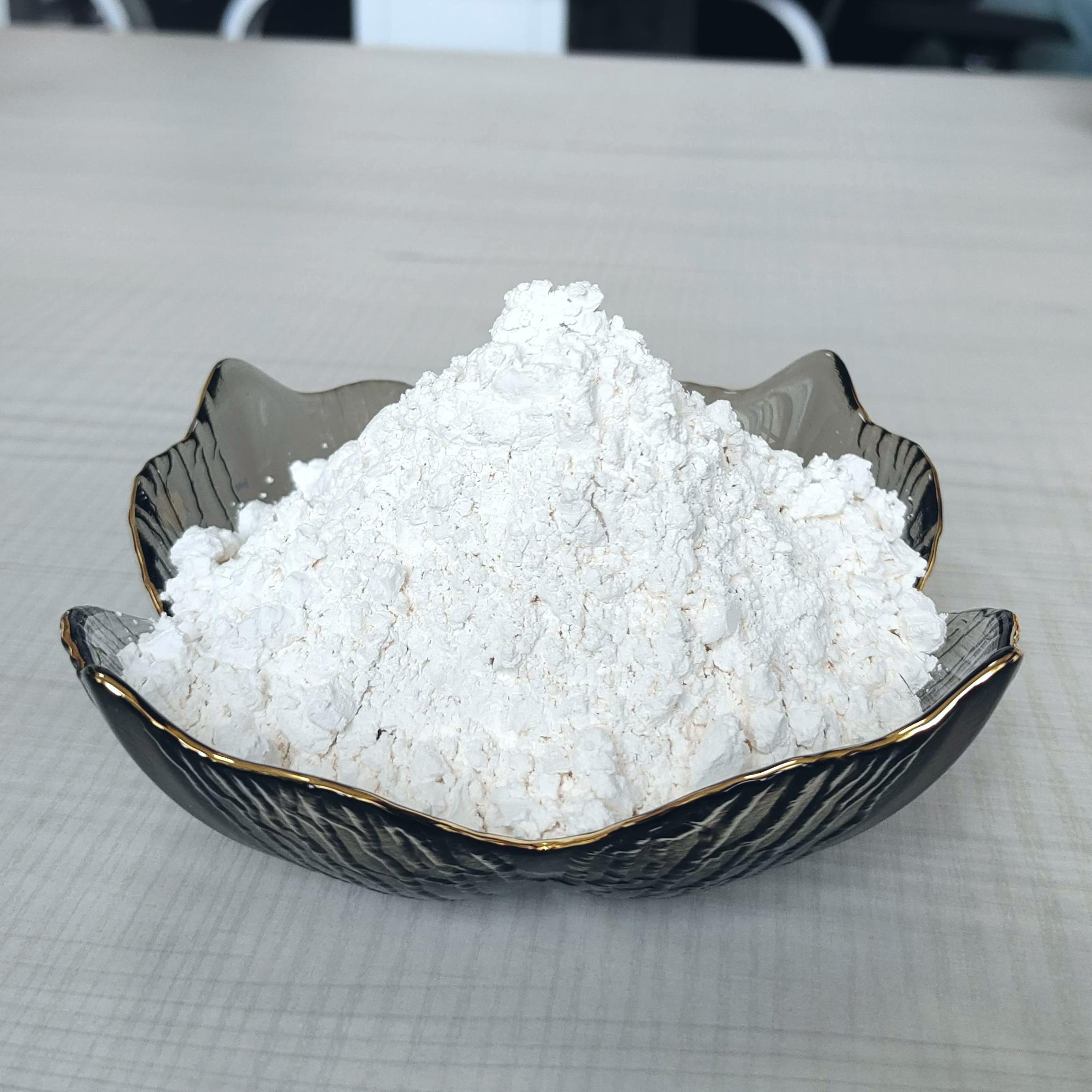

In the world of pigment production, the quest for superior quality, brightness, and opacity is a constant endeavor. One material that has gained significant attention in this domain is high-whiteness calcium carbonate (CaCO3). This versatile mineral not only acts as a functional filler but also plays a crucial role in improving the overall aesthetics and performance of various pigments. In this article, we delve into the characteristics, production processes, and applications of high-whiteness calcium carbonate, shedding light on its importance in the pigment industry.

Table of Contents

- 1. Introduction to High-Whiteness Calcium Carbonate

- 2. Key Properties of High-Whiteness Calcium Carbonate

- 3. Production Process of High-Whiteness Calcium Carbonate

- 4. Applications of High-Whiteness Calcium Carbonate in Pigment Production

- 5. Advantages of Using High-Whiteness Calcium Carbonate

- 6. Environmental Impact and Sustainability

- 7. Future Trends in High-Whiteness Calcium Carbonate Usage

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to High-Whiteness Calcium Carbonate

High-whiteness calcium carbonate is a naturally occurring mineral composed predominantly of CaCO3. Renowned for its exceptional brightness and whiteness, this form of calcium carbonate serves a dual purpose in the pigment production sector: as a functional filler and as a key component that enhances the visual properties of pigments. Since ancient times, calcium carbonate has been utilized in various applications, but modern advancements have led to its refined use in the pigment industry.

Understanding Calcium Carbonate in Pigment Production

Calcium carbonate is pivotal in many industries, particularly in pigments for paints, coatings, plastics, and rubber. Its role extends beyond that of a mere filler; it serves to improve processing, reduce costs, and provide specific performance characteristics that enhance the final product. The high-whiteness variant of calcium carbonate is particularly sought after for its superior light-scattering properties, which contribute to the brightness and opacity of pigments.

2. Key Properties of High-Whiteness Calcium Carbonate

The effectiveness of high-whiteness calcium carbonate in pigment production can be attributed to its unique physical and chemical properties:

Brightness and Whiteness

High-whiteness calcium carbonate boasts remarkable brightness levels, often exceeding 95% reflectance. This quality is crucial for producing bright and vibrant pigments that stand out in end-use applications.

Particle Size Distribution

The particle size distribution is a vital factor affecting the performance of calcium carbonate in pigments. High-whiteness calcium carbonate typically has a controlled particle size, ensuring optimal dispersion in various media, which ultimately leads to better pigment performance.

Surface Area

With a high specific surface area, high-whiteness calcium carbonate enhances the binding properties of pigments, leading to improved adhesion and durability in applications.

Chemical Stability

This mineral exhibits excellent chemical stability, making it resistant to degradation over time. This stability is essential for maintaining the quality and longevity of pigments in various environments.

3. Production Process of High-Whiteness Calcium Carbonate

The production process of high-whiteness calcium carbonate involves several steps, ensuring that the final product meets the stringent quality specifications required for pigment applications.

Mining and Extraction

High-whiteness calcium carbonate is extracted from natural limestone deposits. The quality of the raw material plays a critical role in the final product’s whiteness and purity. Mining operations focus on selecting the highest quality deposits to ensure optimal performance in pigment applications.

Crushing and Grinding

Once extracted, the limestone undergoes crushing and grinding processes to reduce its size. This step is crucial for achieving the desired particle size distribution, which is essential for the effectiveness of the high-whiteness calcium carbonate in pigment formulations.

Classification

After grinding, the material is classified based on particle size. This classification ensures that only the appropriate fractions are used in pigment production, as different applications may require varying particle sizes for optimal performance.

Surface Treatment

To enhance the dispersibility and compatibility of high-whiteness calcium carbonate in various media, surface treatment processes may be employed. These treatments improve the interaction between the filler and the pigment, leading to better performance.

4. Applications of High-Whiteness Calcium Carbonate in Pigment Production

High-whiteness calcium carbonate finds extensive applications in the pigment industry, particularly in the following areas:

Paints and Coatings

In the paints and coatings sector, high-whiteness calcium carbonate is used to improve the opacity and brightness of formulations. It acts as a filler that enhances the overall durability and performance of the coating while reducing production costs.

Plastics

Plastics benefit from the use of high-whiteness calcium carbonate as a filler that enhances their mechanical properties and visual appeal. It improves the opacity and brightness of plastic products, making them more attractive to consumers.

Paper and Ink

In the paper and ink industries, high-whiteness calcium carbonate serves as a functional filler that enhances brightness and improves printability. It contributes to the overall quality and aesthetic appeal of printed materials.

Cosmetics

High-whiteness calcium carbonate is also employed in cosmetic formulations, where it acts as a pigment and a texturizing agent. Its ability to provide opacity and brightness makes it a valuable ingredient in various beauty products.

5. Advantages of Using High-Whiteness Calcium Carbonate

The incorporation of high-whiteness calcium carbonate in pigment production offers numerous advantages:

Cost-Effectiveness

Utilizing high-whiteness calcium carbonate as a filler can significantly reduce production costs, allowing manufacturers to create high-quality pigments without compromising on quality.

Improved Performance

High-whiteness calcium carbonate enhances the brightness, opacity, and durability of pigments, leading to better overall performance in end-use applications.

Environmental Benefits

Calcium carbonate is a naturally occurring mineral that has a lower environmental impact compared to synthetic fillers. Its use in pigment production aligns with sustainability goals and eco-friendly practices.

6. Environmental Impact and Sustainability

As industries increasingly prioritize sustainability, the use of high-whiteness calcium carbonate presents an environmentally friendly alternative. Its natural source minimizes environmental degradation, and its chemical stability ensures that products using this filler maintain their quality over time.

Recycling Potential

Products containing high-whiteness calcium carbonate can often be recycled or repurposed, further contributing to a circular economy. This potential for recycling aligns with global efforts to reduce waste and promote sustainable practices.

7. Future Trends in High-Whiteness Calcium Carbonate Usage

As the demand for high-quality pigments continues to grow, several trends are emerging in the use of high-whiteness calcium carbonate:

Innovative Formulations

Manufacturers are increasingly exploring innovative formulations that leverage the unique properties of high-whiteness calcium carbonate to create advanced pigment products with superior performance characteristics.

Increased Focus on Sustainability

The shift towards eco-friendly and sustainable practices will drive further research into optimizing the use of natural fillers like high-whiteness calcium carbonate, aligning with industry demands for greener solutions.

8. Frequently Asked Questions (FAQs)

What is high-whiteness calcium carbonate?

High-whiteness calcium carbonate is a naturally occurring mineral known for its exceptional brightness and whiteness, making it a valuable filler in various industries, particularly in pigment production.

What are the key applications of high-whiteness calcium carbonate in pigments?

High-whiteness calcium carbonate is widely used in paints, coatings, plastics, paper, and cosmetics to enhance brightness, opacity, and overall performance.

How does high-whiteness calcium carbonate improve pigment performance?

Its unique properties, such as high brightness, controlled particle size, and chemical stability, contribute to improved brightness, opacity, and durability of pigments in various applications.

What are the environmental benefits of using high-whiteness calcium carbonate?

High-whiteness calcium carbonate is a natural mineral with a lower environmental impact compared to synthetic fillers, supporting sustainability and recycling initiatives.

How is high-whiteness calcium carbonate produced?

The production process involves mining, crushing, grinding, classification, and surface treatment to achieve the desired quality and properties for pigment applications.

9. Conclusion

High-whiteness calcium carbonate stands as a cornerstone in the pigment production industry, offering unmatched brightness, opacity, and cost-effectiveness. Its unique properties and versatility make it an essential component for various applications, from paints to cosmetics. As industries continue to prioritize sustainability and innovation, high-whiteness calcium carbonate is poised to play an even more critical role in shaping the future of pigments. By understanding its importance and applications, manufacturers can leverage this remarkable mineral to enhance product quality while adhering to eco-friendly practices.

high-whiteness calcium carbonate

Previous page

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.