30

2025

-

04

Why High-Whiteness Calcium Carbonate is Essential for Quality Coatings

Why High-Whiteness Calcium Carbonate is Essential for Quality Coatings Table of Contents 1. Introduction to High-Whiteness Calcium Carbonate 2. What is Calcium Carbonate? 2.1 Types of Calcium Carbonate 3. Understanding High-Whiteness Calcium Carbonate 3.1 Key Properties 3.2 Importance in Coatings 4. Benefits o

Why High-Whiteness Calcium Carbonate is Essential for Quality Coatings

Table of Contents

- 1. Introduction to High-Whiteness Calcium Carbonate

- 2. What is Calcium Carbonate?

- 3. Understanding High-Whiteness Calcium Carbonate

- 4. Benefits of Using High-Whiteness Calcium Carbonate in Coatings

- 5. Applications of High-Whiteness Calcium Carbonate in Coatings

- 6. Challenges in Using Calcium Carbonate

- 7. Future Trends in Calcium Carbonate Usage

- 8. Conclusion

- 9. FAQs

1. Introduction to High-Whiteness Calcium Carbonate

High-whiteness calcium carbonate is a vital component in the coatings industry. Its unique properties and benefits significantly enhance product quality, making it a preferred choice among manufacturers. As industries strive for optimal performance and aesthetic appeal, understanding the importance of this compound becomes crucial.

2. What is Calcium Carbonate?

Calcium carbonate (CaCO3) is a naturally occurring mineral composed of calcium, carbon, and oxygen. Commonly found in rocks in the form of limestone, chalk, and marble, it serves various purposes in multiple industries, particularly in manufacturing, construction, and food.

2.1 Types of Calcium Carbonate

Calcium carbonate can be categorized into two main types:

- **Ground Calcium Carbonate (GCC)**: Produced by grinding limestone or marble to a fine powder.

- **Precipitated Calcium Carbonate (PCC)**: Manufactured through a chemical reaction, resulting in a finer and more consistent product.

3. Understanding High-Whiteness Calcium Carbonate

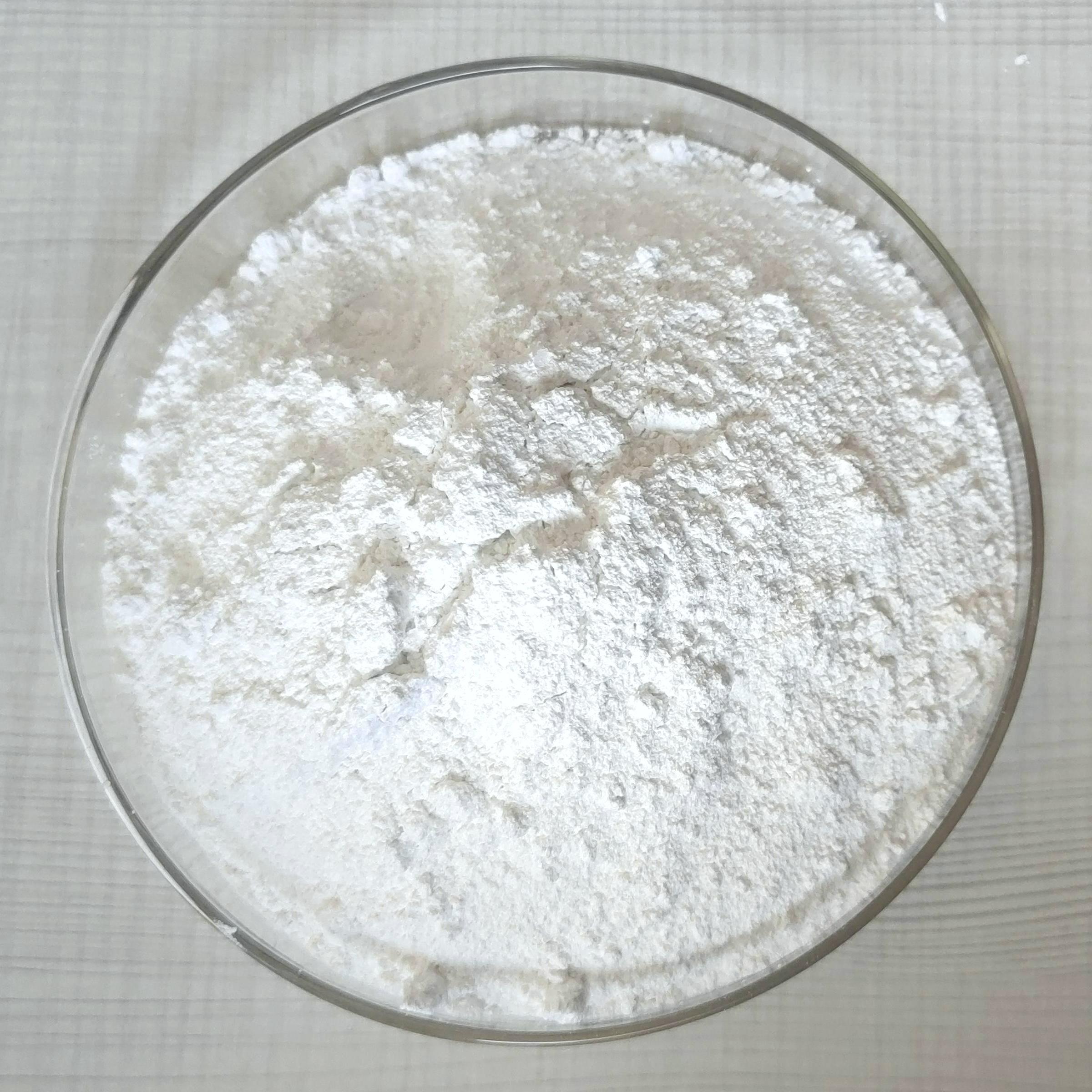

High-whiteness calcium carbonate refers to calcium carbonate with a high degree of whiteness and brightness, making it ideal for use in coatings, especially where aesthetic appearance is paramount.

3.1 Key Properties

The key properties of high-whiteness calcium carbonate include:

- **High Brightness**: Provides excellent opacity and whiteness, enhancing the visual quality of coatings.

- **Fine Particle Size**: Its small particle size improves dispersion in liquid formulations and contributes to a smoother finish.

- **Chemical Stability**: It remains stable under various environmental conditions, ensuring durability in coatings.

3.2 Importance in Coatings

The importance of high-whiteness calcium carbonate in coatings cannot be overstated. Its ability to improve opacity, gloss, and durability directly impacts the overall quality of the final product. As manufacturers seek to meet evolving consumer demands, utilizing high-whiteness calcium carbonate becomes essential.

4. Benefits of Using High-Whiteness Calcium Carbonate in Coatings

Integrating high-whiteness calcium carbonate into coating formulations offers numerous benefits:

4.1 Aesthetic Appeal

The high brightness and opacity of calcium carbonate enhance the visual appeal of paints and coatings, making them look more vibrant and appealing. This is especially important in decorative coatings where aesthetics are a primary concern.

4.2 Performance Enhancement

High-whiteness calcium carbonate improves the performance of coatings by:

- **Increasing Opacity**: Reduces the need for multiple coats, saving time and resources.

- **Enhancing Durability**: Contributes to the toughness and resistance of coatings against wear and environmental factors.

- **Improving Flow and Application**: Offers better workability during application, leading to a smoother finish.

4.3 Cost-Effectiveness

Utilizing high-whiteness calcium carbonate can be a cost-effective solution for manufacturers. By reducing the need for more expensive pigments and fillers, it helps lower production costs while maintaining quality.

5. Applications of High-Whiteness Calcium Carbonate in Coatings

High-whiteness calcium carbonate is widely used in various coating applications, including:

- **Architectural Coatings**: Used in residential and commercial paints to achieve superior finish and durability.

- **Industrial Coatings**: Incorporated in protective coatings to enhance resistance to corrosion.

- **Automotive Paints**: Serves as a filler to improve the finish of automotive coatings.

6. Challenges in Using Calcium Carbonate

Despite its many benefits, the use of high-whiteness calcium carbonate in coatings also presents certain challenges:

- **Quality Variability**: Sourcing high-quality calcium carbonate can be difficult, affecting consistency in coatings.

- **Compatibility Issues**: It may not always blend well with other components in a formulation, necessitating careful formulation work.

7. Future Trends in Calcium Carbonate Usage

As industries evolve, the demand for high-whiteness calcium carbonate is likely to grow. Future trends may include:

- **Innovation in Sourcing**: Enhanced methods for extracting and processing calcium carbonate to improve quality and sustainability.

- **Integration with Eco-Friendly Products**: As sustainability becomes a priority, high-whiteness calcium carbonate is expected to play a role in developing environmentally friendly coatings.

8. Conclusion

High-whiteness calcium carbonate stands as a cornerstone in the coatings industry, crucial for achieving quality, performance, and aesthetic appeal. Its benefits extend beyond mere appearance, enhancing durability and cost-effectiveness in various applications. As manufacturers continue to prioritize quality, understanding and utilizing high-whiteness calcium carbonate will remain essential for producing superior coatings that meet market demands.

9. FAQs

1. What is the primary use of high-whiteness calcium carbonate in coatings?

High-whiteness calcium carbonate is primarily used to enhance opacity, brightness, and durability in various coatings.

2. How does high-whiteness calcium carbonate improve paint performance?

It improves paint performance by increasing opacity, enhancing chemical stability, and allowing for smoother application.

3. Are there any downsides to using high-whiteness calcium carbonate?

Potential downsides include sourcing quality materials and compatibility issues in certain formulations.

4. Can high-whiteness calcium carbonate be used in eco-friendly coatings?

Yes, high-whiteness calcium carbonate is increasingly being used in eco-friendly coatings as manufacturers focus on sustainability.

5. How do manufacturers ensure the quality of high-whiteness calcium carbonate?

Manufacturers ensure quality by sourcing from reputable suppliers and utilizing advanced processing techniques to maintain consistency in particle size and brightness.

high-whiteness calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.