06

2025

-

05

How Ultrafine Calcium Carbonate Manufacturers Are Revolutionizing the Paint Industry

How Ultrafine Calcium Carbonate Manufacturers Are Revolutionizing the Paint Industry Table of Contents Introduction to Ultrafine Calcium Carbonate The Role of Calcium Carbonate in Paint Formulations Benefits of Ultrafine Calcium Carbonate in Paints Manufacturing Process of Ultrafine Calcium Carbonate Applications of Ultrafine Calcium Carbonate in Paints Environmental Impact and Sustai

How Ultrafine Calcium Carbonate Manufacturers Are Revolutionizing the Paint Industry

Table of Contents

- Introduction to Ultrafine Calcium Carbonate

- The Role of Calcium Carbonate in Paint Formulations

- Benefits of Ultrafine Calcium Carbonate in Paints

- Manufacturing Process of Ultrafine Calcium Carbonate

- Applications of Ultrafine Calcium Carbonate in Paints

- Environmental Impact and Sustainability of Ultrafine Calcium Carbonate

- Future Trends in Paint Technology Using Ultrafine Calcium Carbonate

- Conclusion

- FAQs

Introduction to Ultrafine Calcium Carbonate

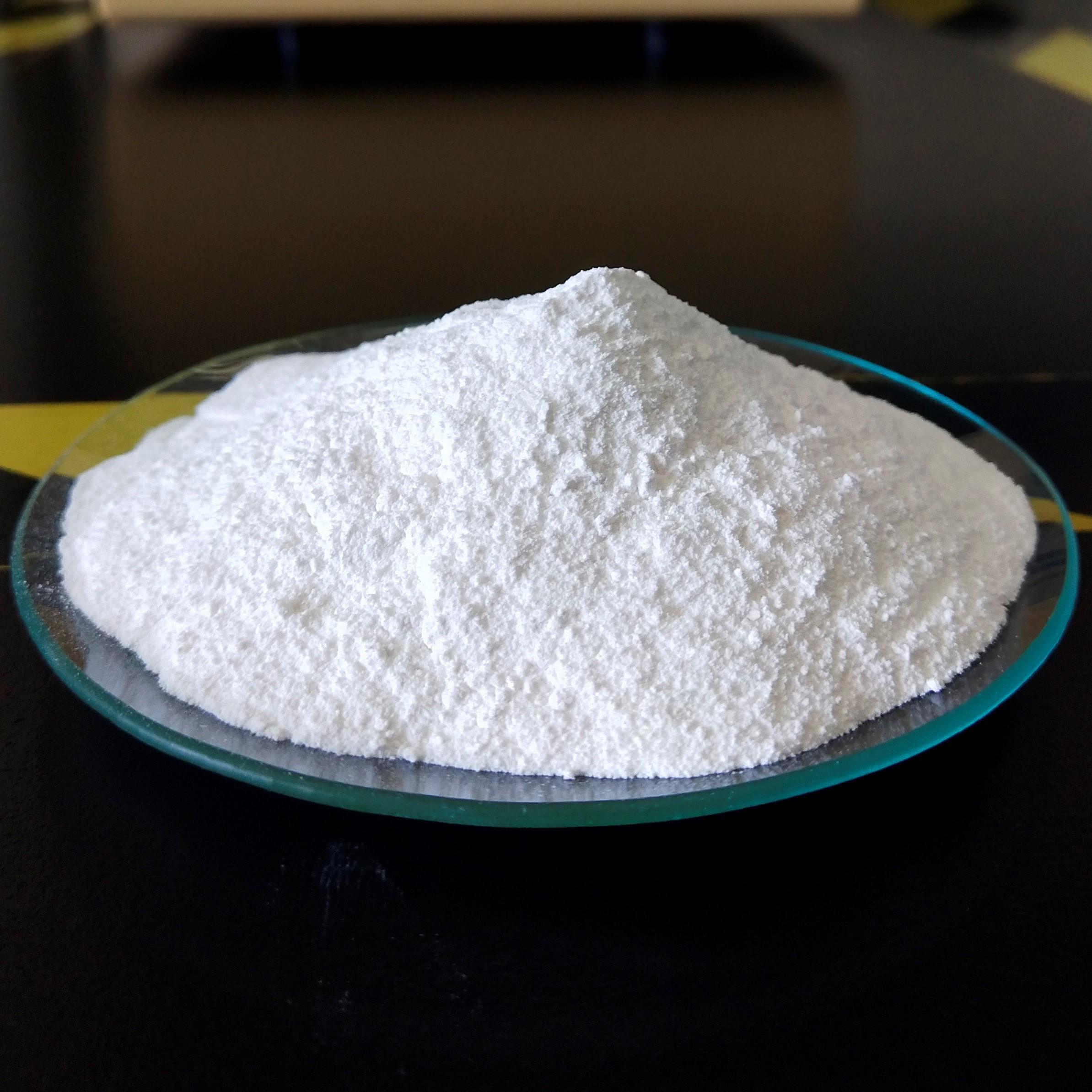

Ultrafine calcium carbonate (UCC) has emerged as a pivotal ingredient in the paint industry, revolutionizing formulations and enhancing product performance. As manufacturers seek to improve the quality and durability of their paints, the introduction of UCC has provided a solution that not only meets but exceeds evolving market demands. This article delves into the multifaceted role of ultrafine calcium carbonate, examining its benefits, manufacturing processes, and applications within the paint sector.

The Role of Calcium Carbonate in Paint Formulations

Calcium carbonate, a naturally occurring mineral, has long been used as a filler in various industries, including construction, plastics, and the paint sector. In paint formulations, calcium carbonate serves multiple purposes:

- **Filler Material**: It provides bulk and texture to paint, ensuring smooth application and improved coverage.

- **Pigment Extender**: UCC assists in enhancing the opacity and brightness of paint, making colors more vibrant.

- **Cost Efficiency**: Using UCC can reduce the overall cost of paint formulations while maintaining quality.

UCC is a finely milled version of calcium carbonate that offers superior performance. Its smaller particle size results in a higher surface area, leading to improved interactions with other components in the paint.

Benefits of Ultrafine Calcium Carbonate in Paints

The use of ultrafine calcium carbonate in paint formulations has garnered attention due to its myriad benefits, including:

1. Enhanced Gloss and Finish

UCC contributes to a glossier finish, enhancing the aesthetic appeal of paints. Its fine particles help to create a smooth surface, reducing the appearance of imperfections.

2. Improved Coverage and Opacity

Ultrafine calcium carbonate increases the opacity of paint, allowing for better coverage with fewer coats. This not only saves time during application but also reduces overall material costs.

3. Increased Durability

Paints formulated with UCC exhibit improved durability and resistance to cracking, chipping, and fading. This longevity is particularly important in exterior paints exposed to harsh weather conditions.

4. Better Rheological Properties

The addition of UCC enhances the flow and leveling characteristics of paints, leading to easier application and a more uniform finish. This is crucial for both professional painters and DIY enthusiasts.

5. Eco-Friendly Option

As manufacturers increasingly focus on sustainable practices, UCC presents an environmentally friendly alternative. It is derived from abundant natural resources and is non-toxic, making it a safer choice for consumers and the environment.

Manufacturing Process of Ultrafine Calcium Carbonate

The production of ultrafine calcium carbonate involves several key processes that ensure the final product meets high standards of quality and performance.

1. Mining and Crushing

The journey begins with the extraction of limestone, the primary source of calcium carbonate. After mining, the limestone is crushed to create smaller particles, which facilitates further processing.

2. Milling

The crushed limestone undergoes a milling process, where it is ground to achieve ultrafine particle sizes. Advanced milling technologies, such as jet milling and ball milling, are employed to produce UCC with the desired characteristics.

3. Surface Modification

To enhance the performance of UCC in paint applications, manufacturers often modify the surface of the particles. This can include treatments that improve dispersion and compatibility with resin systems used in paints.

4. Quality Control

Quality control is a critical step in the manufacturing process. Rigorous testing ensures that UCC meets specified parameters, such as particle size, purity, and chemical composition.

Applications of Ultrafine Calcium Carbonate in Paints

Ultrafine calcium carbonate finds diverse applications in various types of paints, ranging from decorative to industrial coatings.

1. Architectural Paints

In architectural paints, UCC enhances the aesthetic quality and longevity of coatings, making it a preferred choice for both interior and exterior applications.

2. Industrial Coatings

Industrial coatings benefit from the improved durability and resistance properties imparted by UCC, ensuring that surfaces remain protected from corrosion and wear.

3. Automotive Paints

In the automotive sector, UCC is utilized to achieve high gloss finishes and superior color retention, enhancing the overall visual appeal of vehicles.

4. Specialty Coatings

Specialty coatings, including those used for marine applications, also leverage the benefits of UCC to provide added protection against harsh environmental conditions.

Environmental Impact and Sustainability of Ultrafine Calcium Carbonate

Sustainability is a core consideration in the production and application of ultrafine calcium carbonate.

1. Natural Resource Utilization

UCC is sourced from limestone, a naturally abundant resource. The extraction process is typically less harmful to the environment compared to synthetic alternatives.

2. Non-Toxic and Safe

Being non-toxic, UCC poses minimal health risks to consumers and workers in the paint industry. This safety profile is increasingly important as regulatory pressures around chemical safety continue to grow.

3. Contribution to Sustainable Manufacturing

Integrating UCC into paint formulations can help manufacturers achieve sustainability goals by reducing the carbon footprint associated with conventional paint production.

Future Trends in Paint Technology Using Ultrafine Calcium Carbonate

As the paint industry continues to evolve, several trends are emerging that highlight the role of ultrafine calcium carbonate.

1. Smart Coatings

The development of smart coatings, which can respond to environmental stimuli, is an area of increasing interest. UCC can contribute to the formulation of these advanced materials, enhancing their properties.

2. Biodegradable Paints

With a growing demand for eco-friendly products, the formulation of biodegradable paints using UCC is on the horizon. This would align with consumer preferences for sustainable products.

3. Enhanced Performance Products

Continued research in nanotechnology may yield even finer grades of calcium carbonate, pushing the boundaries of paint performance further and leading to the creation of superior coatings.

Conclusion

Ultrafine calcium carbonate manufacturers are indeed revolutionizing the paint industry by introducing products that enhance performance, reduce costs, and promote sustainability. The unique properties of UCC, along with its diverse applications across various paint types, position it as a vital ingredient for the future of paint formulations. As the industry moves towards eco-friendly practices and advanced technologies, the role of ultrafine calcium carbonate is set to expand, ensuring that manufacturers can meet changing consumer demands while enhancing the quality of their products.

FAQs

1. What is ultrafine calcium carbonate?

Ultrafine calcium carbonate (UCC) is a finely milled form of calcium carbonate that offers superior performance in various applications, including paints.

2. How does UCC improve paint quality?

UCC enhances paint quality by providing better coverage, improved gloss, increased durability, and enhanced application properties.

3. Is ultrafine calcium carbonate environmentally friendly?

Yes, UCC is derived from natural resources and is non-toxic, making it a safer and more sustainable choice for paint formulations.

4. What industries use ultrafine calcium carbonate?

UCC is used in various industries, including construction, plastics, automotive, and coatings, particularly in paint manufacturing.

5. What are the future trends for ultrafine calcium carbonate in the paint industry?

Future trends include the development of smart coatings, biodegradable paints, and enhanced performance products utilizing advancements in nanotechnology.

ultrafine calcium carbonate manufacturers

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.