12

2025

-

05

Key Properties of Colloidal Nano Calcium Carbonate for Enhanced Material Performance

Key Properties of Colloidal Nano Calcium Carbonate for Enhanced Material Performance Table of Contents 1. Introduction to Colloidal Nano Calcium Carbonate 2. Key Properties of Colloidal Nano Calcium Carbonate 2.1 Nanoscale Dimensions 2.2 High Surface Area 2.3 Excellent Dispersion Stability 2.4 Chemical Stability and Reactivity

Key Properties of Colloidal Nano Calcium Carbonate for Enhanced Material Performance

Table of Contents

- 1. Introduction to Colloidal Nano Calcium Carbonate

- 2. Key Properties of Colloidal Nano Calcium Carbonate

- 2.1 Nanoscale Dimensions

- 2.2 High Surface Area

- 2.3 Excellent Dispersion Stability

- 2.4 Chemical Stability and Reactivity

- 3. Applications of Colloidal Nano Calcium Carbonate

- 3.1 Use in Plastics and Polymers

- 3.2 Role in Paints and Coatings

- 3.3 Paper and Pulp Industry

- 3.4 Applications in Cosmetics

- 4. Benefits of Using Colloidal Nano Calcium Carbonate

- 5. Challenges and Considerations

- 6. Future Trends in Colloidal Nano Calcium Carbonate

- 7. Conclusion

- 8. Frequently Asked Questions

1. Introduction to Colloidal Nano Calcium Carbonate

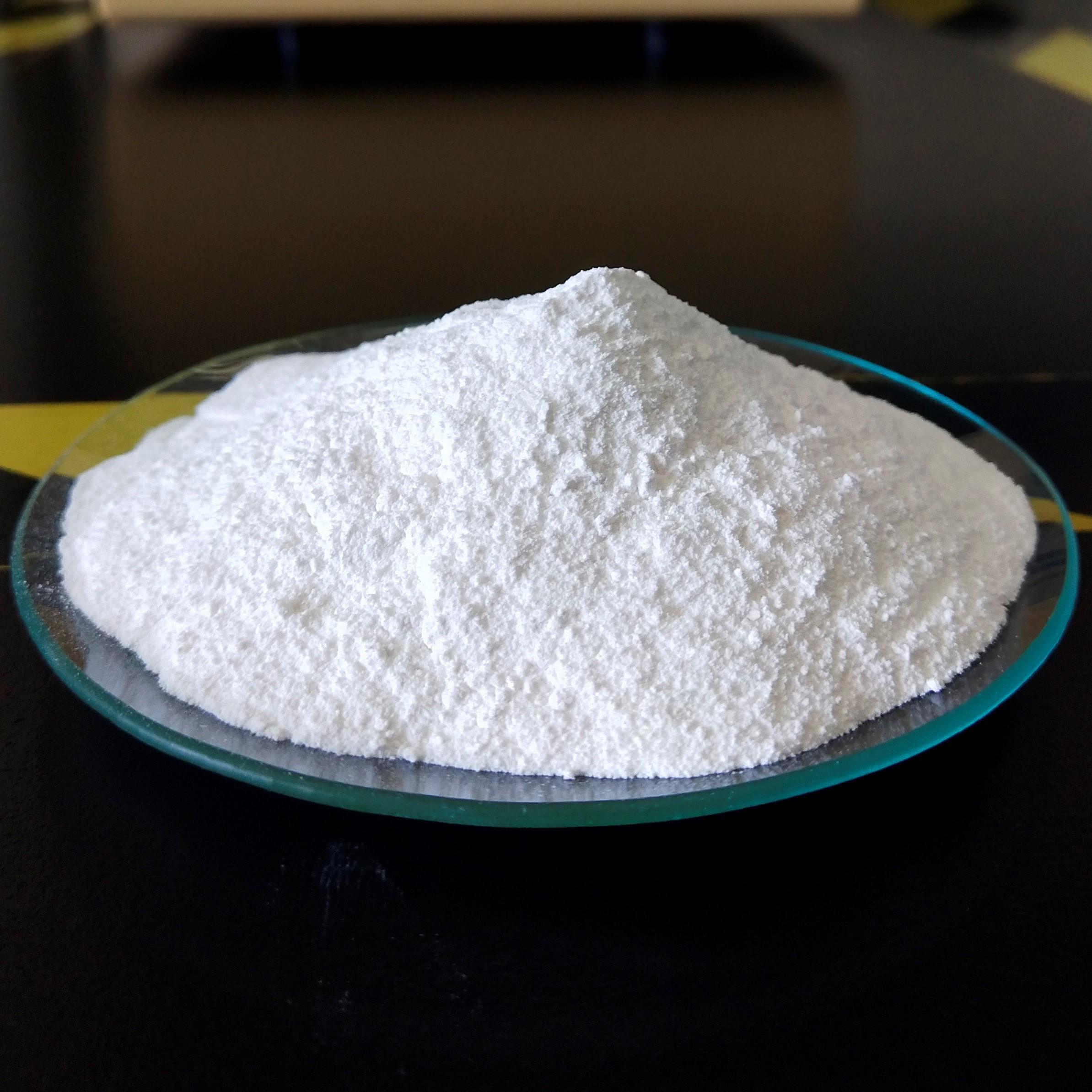

Colloidal nano calcium carbonate (CaCO3) is a fine particulate material, characterized by its extremely small particle size, typically less than 100 nanometers. This innovative form of calcium carbonate combines the traditional benefits of calcium carbonate with enhanced properties brought forth by its nanoscale dimensions. The resultant material is known for its superior performance in a variety of applications, making it a pivotal component in the fields of pigments, coatings, plastics, and more.

The demand for colloidal nano calcium carbonate has surged across industries due to its adaptability and effectiveness. Understanding its key properties is essential for manufacturers aiming to improve product quality and innovate their production processes. In this article, we will explore the properties, applications, benefits, challenges, and future trends associated with colloidal nano calcium carbonate, providing a comprehensive overview for professionals in the chemical and materials sectors.

2. Key Properties of Colloidal Nano Calcium Carbonate

Understanding the defining characteristics of colloidal nano calcium carbonate is crucial for leveraging its potential in various applications. Below, we discuss the primary properties that contribute to its enhanced performance.

2.1 Nanoscale Dimensions

The most significant property of colloidal nano calcium carbonate is its nanoscale dimension. These tiny particles exhibit unique physical and chemical properties, which differentiate them from their larger counterparts. The small size increases the material's surface area relative to its volume, enhancing reactivity and interaction with other materials. This property is particularly beneficial in applications requiring high precision and performance, such as in drug delivery systems and advanced composites.

2.2 High Surface Area

Colloidal nano calcium carbonate boasts an exceptionally high surface area compared to traditional calcium carbonate. This increased surface area facilitates better interactions with other substances, promoting improved adhesion, dispersion, and stability within composite materials. As a result, products containing nano CaCO3 tend to exhibit enhanced mechanical properties, such as increased tensile strength and durability, making it a preferred choice for manufacturers seeking high-performance materials.

2.3 Excellent Dispersion Stability

Another noteworthy property of colloidal nano calcium carbonate is its excellent dispersion stability in various mediums. The enhanced stability arises from the small particle size, which reduces sedimentation and agglomeration. This stability is crucial in applications such as paints and coatings, where uniformity and consistency significantly affect the finished product's quality and appearance. Furthermore, it allows for easier incorporation into different matrices, thereby broadening its application scope.

2.4 Chemical Stability and Reactivity

Colloidal nano calcium carbonate exhibits remarkable chemical stability, which is vital for various applications. Its resistance to degradation under environmental conditions ensures that products maintain their properties over time. Additionally, the material's reactivity can be advantageous in specific processes where chemical interactions are beneficial, such as in the formulation of responsive materials or catalysts.

3. Applications of Colloidal Nano Calcium Carbonate

The versatility of colloidal nano calcium carbonate allows it to be utilized in numerous sectors. Below are some key applications that highlight its importance in enhancing material performance.

3.1 Use in Plastics and Polymers

In the plastics industry, colloidal nano calcium carbonate serves as a filler that improves the mechanical and thermal properties of polymers. Its incorporation leads to enhanced strength, rigidity, and thermal stability in plastic products. Moreover, it can reduce production costs by replacing more expensive fillers without compromising quality. Manufacturers are increasingly turning to nano CaCO3 to create lightweight, durable, and cost-effective plastic products.

3.2 Role in Paints and Coatings

Colloidal nano calcium carbonate plays a crucial role in the formulation of paints and coatings. It acts as a pigment extender, improving opacity, brightness, and whiteness while reducing the quantity of expensive pigments required. Additionally, its excellent dispersion stability ensures uniform application and enhances the durability of coatings. This results in longer-lasting finishes that withstand environmental wear and tear.

3.3 Paper and Pulp Industry

In the paper and pulp industry, colloidal nano calcium carbonate is used to enhance the brightness and opacity of paper products. The fine particles improve the paper's surface quality, leading to better printability and visual appeal. Furthermore, using nano CaCO3 can reduce the amount of wood pulp needed, promoting more sustainable production practices within the industry.

3.4 Applications in Cosmetics

The cosmetic industry is also benefiting from the unique properties of colloidal nano calcium carbonate. Its fine particle size allows it to serve as a bulking agent and a skin-conditioning agent in various formulations. Moreover, it provides a smooth texture and enhances the product's feel, making it an attractive ingredient for manufacturers aiming to create high-quality cosmetic products.

4. Benefits of Using Colloidal Nano Calcium Carbonate

Incorporating colloidal nano calcium carbonate into products offers numerous benefits that can significantly enhance material performance. Some key advantages include:

- **Improved Mechanical Properties**: Enhanced strength and durability due to the high surface area and nanoscale properties.

- **Cost-Effectiveness**: Reduces dependency on expensive fillers, leading to lower production costs.

- **Environmental Sustainability**: Promotes the use of less natural resources in manufacturing processes, aligning with sustainability goals.

- **Versatile Applications**: Adaptability across various industries, allowing manufacturers to innovate and expand their product lines.

These benefits make colloidal nano calcium carbonate a valuable asset for producers seeking to enhance their material performance and operational efficiency.

5. Challenges and Considerations

Despite the advantages, the use of colloidal nano calcium carbonate does come with certain challenges and considerations:

- **Handling and Safety**: Due to its nanoscale size, proper handling procedures must be in place to mitigate inhalation or exposure risks.

- **Regulatory Compliance**: Certain industries may have stringent regulations regarding the use of nanomaterials, requiring thorough documentation and testing.

- **Cost and Sourcing**: While colloidal nano calcium carbonate can reduce overall production costs, the initial investment for high-quality nano CaCO3 may be higher than traditional materials.

Understanding these challenges is vital for manufacturers to ensure safe, compliant, and efficient utilization of colloidal nano calcium carbonate in their products.

6. Future Trends in Colloidal Nano Calcium Carbonate

As technology continues to advance, the future of colloidal nano calcium carbonate appears promising. Emerging trends include:

- **Innovative Formulations**: Increased research into new formulations that incorporate nano CaCO3 for specialized applications, particularly in high-tech industries.

- **Sustainable Practices**: A growing emphasis on eco-friendly materials may drive further development of sustainable sources and production methods for colloidal nano calcium carbonate.

- **Enhanced Functional Properties**: Continued exploration of the unique properties of nano CaCO3 to enhance functionality across diverse applications, including electronics and pharmaceuticals.

These trends indicate that colloidal nano calcium carbonate will play an increasingly significant role in advancing material performance across various industries.

7. Conclusion

In summary, colloidal nano calcium carbonate is a transformative material that offers numerous advantages across various applications. Its unique properties, including nanoscale dimensions, high surface area, excellent dispersion stability, and chemical stability, contribute to enhanced material performance in plastics, coatings, paper, and cosmetics. By incorporating this innovative material, manufacturers can achieve improved mechanical properties, cost-effectiveness, and sustainable practices.

As industries continue to evolve, the demand for colloidal nano calcium carbonate is likely to grow, paving the way for new applications and advancements. By staying informed about the latest trends and challenges, professionals can leverage the benefits of colloidal nano calcium carbonate, ensuring they remain competitive in an ever-changing market.

8. Frequently Asked Questions

1. What is colloidal nano calcium carbonate?

Colloidal nano calcium carbonate is a form of calcium carbonate characterized by its extremely small particle sizes, typically less than 100 nanometers, which enhances its performance in various applications.

2. How does colloidal nano calcium carbonate improve material performance?

Its high surface area, excellent dispersion stability, and unique nanoscale properties contribute to enhanced mechanical strength, durability, and cost-effectiveness in products.

3. What are the primary applications of colloidal nano calcium carbonate?

Colloidal nano calcium carbonate is used in plastics, paints and coatings, the paper and pulp industry, and cosmetics, among others.

4. Are there safety concerns associated with using nanomaterials like colloidal nano calcium carbonate?

Yes, proper handling procedures should be observed to minimize any inhalation or exposure risks, and regulatory compliance is essential in certain industries.

5. What are the future trends for colloidal nano calcium carbonate?

Future trends include innovative formulations, sustainable practices, and enhanced functional properties, which will drive its use across various industries.

colloidal nano calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.