28

2025

-

04

Why Colloidal Nano Calcium Carbonate is the Future of Pigment and Dye Manufacturing

Introduction to Colloidal Nano Calcium Carbonate Colloidal nano calcium carbonate (CNCC) has emerged as a pivotal material in the pigment and dye manufacturing industry. Its unique properties offer innovative solutions to longstanding challenges within this field. In this article, we will explore the significance of CNCC, its advantages over traditional materials, and how it is reshaping the lan

Introduction to Colloidal Nano Calcium Carbonate

Colloidal nano calcium carbonate (CNCC) has emerged as a pivotal material in the pigment and dye manufacturing industry. Its unique properties offer innovative solutions to longstanding challenges within this field. In this article, we will explore the significance of CNCC, its advantages over traditional materials, and how it is reshaping the landscape of pigment and dye production.

Understanding Colloidal Nano Calcium Carbonate

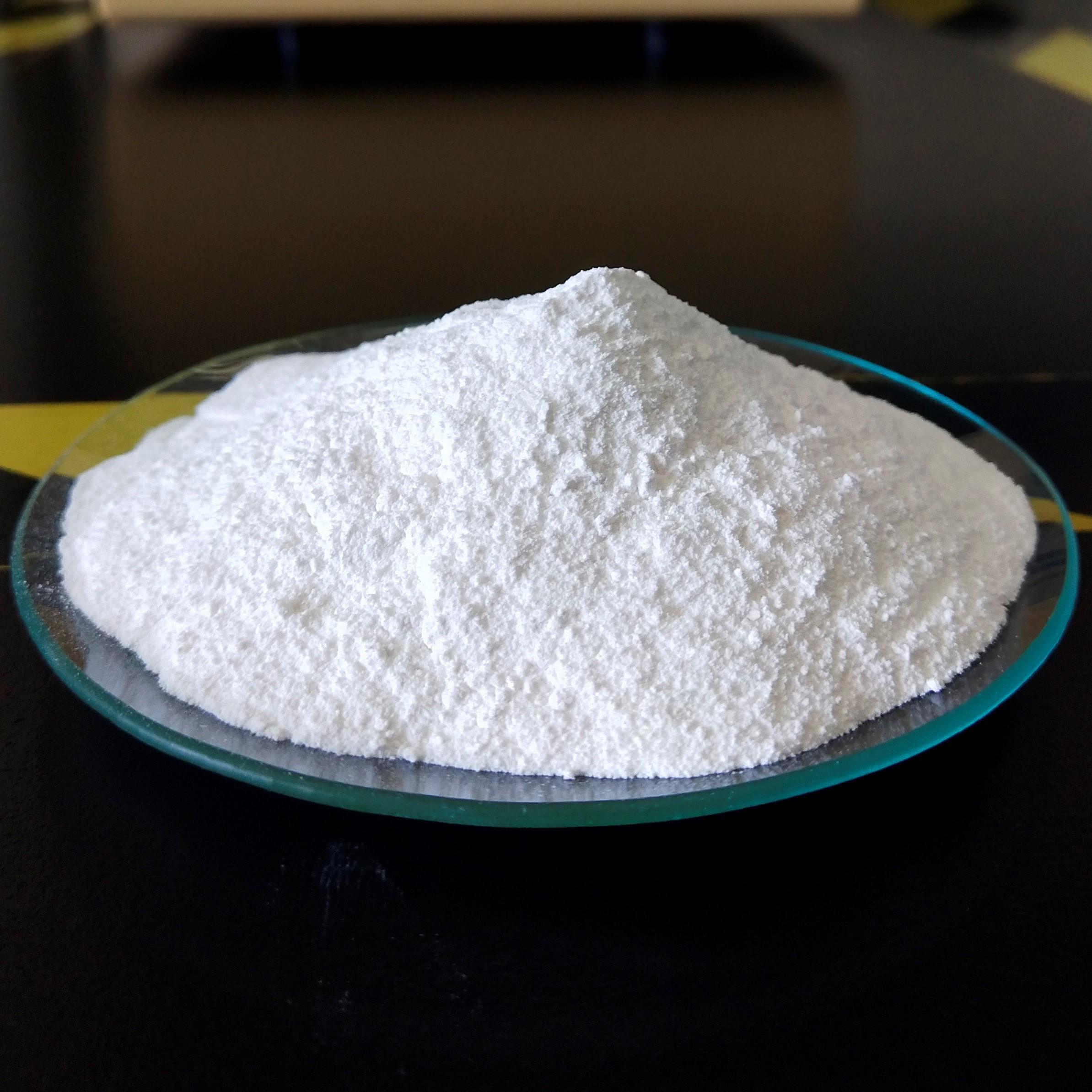

Colloidal nano calcium carbonate is a fine particulate form of calcium carbonate characterized by its nanoscale dimensions. When dispersed in a medium, these nanoparticles create a colloidal solution that can enhance product performance in various applications. The nanoscale size results in an increased surface area, which provides numerous benefits in the formulation of pigments and dyes.

The Composition and Properties of Colloidal Nano Calcium Carbonate

The chemical composition of CNCC is primarily calcium carbonate (CaCO3), a naturally occurring mineral. However, what sets colloidal nano calcium carbonate apart is its particle size, usually ranging from 1 to 100 nanometers. This small size contributes to several key properties, including:

- **High Surface Area**: The increased surface area allows for better interaction with other materials, enhancing dispersion and stability.

- **Improved Stability**: The nano-sized particles improve suspension stability, preventing sedimentation and ensuring uniformity in products.

- **Enhanced Light Scattering**: CNCC can exhibit superior light scattering properties, making it an ideal choice for producing vibrant colors in pigments and dyes.

The Role of Colloidal Nano Calcium Carbonate in Pigment Manufacturing

In pigment manufacturing, the primary goal is to create colors that are not only vibrant but also stable and long-lasting. CNCC plays a crucial role in achieving these objectives. Here are several ways in which colloidal nano calcium carbonate is transforming pigment production:

1. Enhancing Color Brightness and Opacity

One of the notable advantages of CNCC is its ability to enhance color brightness and opacity. The high refractive index of nano-calcium carbonate allows for better light scattering, resulting in more vibrant and intense colors. This characteristic is particularly valuable in producing high-quality pigments for paints, coatings, and inks.

2. Improving Dispersion and Stability

The unique properties of CNCC facilitate better dispersion in various media, resulting in a more homogeneous product. This enhanced dispersion minimizes issues related to clumping and settling, ensuring that pigments remain evenly distributed throughout the medium. This leads to improved stability and consistency in the final product.

3. Reducing Environmental Impact

As industries move towards more sustainable practices, the use of colloidal nano calcium carbonate aligns with these goals. Its production typically has a lower environmental footprint compared to traditional pigments. Additionally, CNCC can be sourced from sustainable materials, further reducing its impact on the environment.

Case Study: CNCC in Paint Production

In the paint industry, for instance, the incorporation of CNCC has led to significant improvements in product quality. Manufacturers report that using CNCC in their formulations results in paints that not only exhibit superior color vibrancy but also improved durability and weather resistance.

The Impact of Colloidal Nano Calcium Carbonate on Dye Manufacturing

Dye manufacturing also stand to benefit immensely from the innovative properties of CNCC. The following sections will delve into the specific advantages CNCC offers in dye production.

1. Enhanced Color Fastness

Color fastness is a critical property of dyes, determining how well a color retains its hue when subjected to various environmental factors such as light and washing. The incorporation of CNCC can enhance the adherence of dyes to substrates, improving overall color fastness.

2. Improved Solubility and Compatibility

Given the small particle size of colloidal nano calcium carbonate, it can improve the solubility and compatibility of dyes in various applications. This is particularly beneficial in textile dyeing, where uniform color application is crucial for product quality.

3. Tailored Functional Properties

Another advantage of using CNCC in dye manufacturing is the ability to tailor functional properties. By adjusting the formulation and concentration of CNCC, manufacturers can create dyes with specific characteristics, such as altered viscosity or enhanced absorption rates, to meet diverse application needs.

Innovation in Textile Dye Applications

A leading textile manufacturer recently adopted CNCC in their dye formulations, resulting in a product that not only achieved vibrant colors but also offered improved wash and light fastness. This innovation has set a new standard in the textile industry, showcasing the potential of CNCC to enhance dye performance.

Future Trends in Pigment and Dye Manufacturing with Colloidal Nano Calcium Carbonate

As the pigment and dye manufacturing landscape continues to evolve, several trends indicate that colloidal nano calcium carbonate will play a pivotal role in shaping the future of these industries.

1. Increased Demand for Eco-Friendly Solutions

With rising environmental awareness, there is a growing demand for eco-friendly alternatives in the pigment and dye market. CNCC, being derived from natural sources and exhibiting lower toxicity, positions itself as a leading candidate for sustainable production practices.

2. Technological Advancements and Research

Ongoing research into the properties and applications of colloidal nano calcium carbonate is expected to yield innovative formulations and technologies. This could lead to the development of new pigments and dyes that were previously unattainable, expanding the possibilities in color manufacturing.

3. Customization and Specialized Products

As consumer preferences shift towards personalized and specialized products, manufacturers will increasingly seek to customize their pigment and dye formulations. CNCC’s versatility allows for easy adjustments in formulation, enabling manufacturers to create unique colors tailored to specific needs.

Challenges and Considerations in Using Colloidal Nano Calcium Carbonate

Despite its many advantages, the implementation of colloidal nano calcium carbonate in pigment and dye manufacturing does not come without challenges.

1. Cost of Production

The production of CNCC can be more expensive compared to conventional calcium carbonate. Manufacturers need to weigh the benefits against the costs to determine the feasibility of incorporating CNCC into their processes.

2. Potential Regulatory Considerations

As with any new material, there may be regulatory hurdles to overcome. Ensuring compliance with safety and environmental regulations will be essential for manufacturers looking to adopt CNCC in their products.

3. Knowledge and Expertise

The successful integration of CNCC in manufacturing processes requires specialized knowledge. Training and education for staff and stakeholders are necessary to maximize the benefits of this innovative material.

Frequently Asked Questions

1. What is colloidal nano calcium carbonate?

Colloidal nano calcium carbonate is a fine particulate form of calcium carbonate characterized by its nanoscale dimensions, enhancing its properties for various applications, particularly in pigment and dye manufacturing.

2. How does CNCC improve pigment quality?

CNCC enhances pigment quality by increasing color brightness and opacity, improving dispersion and stability, and reducing environmental impact.

3. What role does CNCC play in dye manufacturing?

In dye manufacturing, CNCC improves color fastness, solubility, and allows for tailored functional properties, enhancing overall product performance.

4. Are there any environmental benefits to using CNCC?

Yes, CNCC is often sourced from sustainable materials and has a lower environmental footprint compared to traditional pigments, aligning with eco-friendly manufacturing practices.

5. What challenges are associated with the use of colloidal nano calcium carbonate?

Challenges include the cost of production, potential regulatory considerations, and the need for specialized knowledge to effectively implement CNCC in manufacturing processes.

Conclusion

Colloidal nano calcium carbonate is poised to revolutionize the pigment and dye manufacturing industry through its unique properties and benefits. By enhancing color quality, improving stability, and aligning with sustainability goals, CNCC presents a promising future for manufacturers looking to innovate. With ongoing research and advancements, the full potential of colloidal nano calcium carbonate in this sector is just beginning to unfold, paving the way for more vibrant, sustainable, and high-performance products in the years to come.

colloidal nano calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.