26

2025

-

04

Unlock the Benefits of Customized High-Whiteness Calcium Carbonate for Your Products

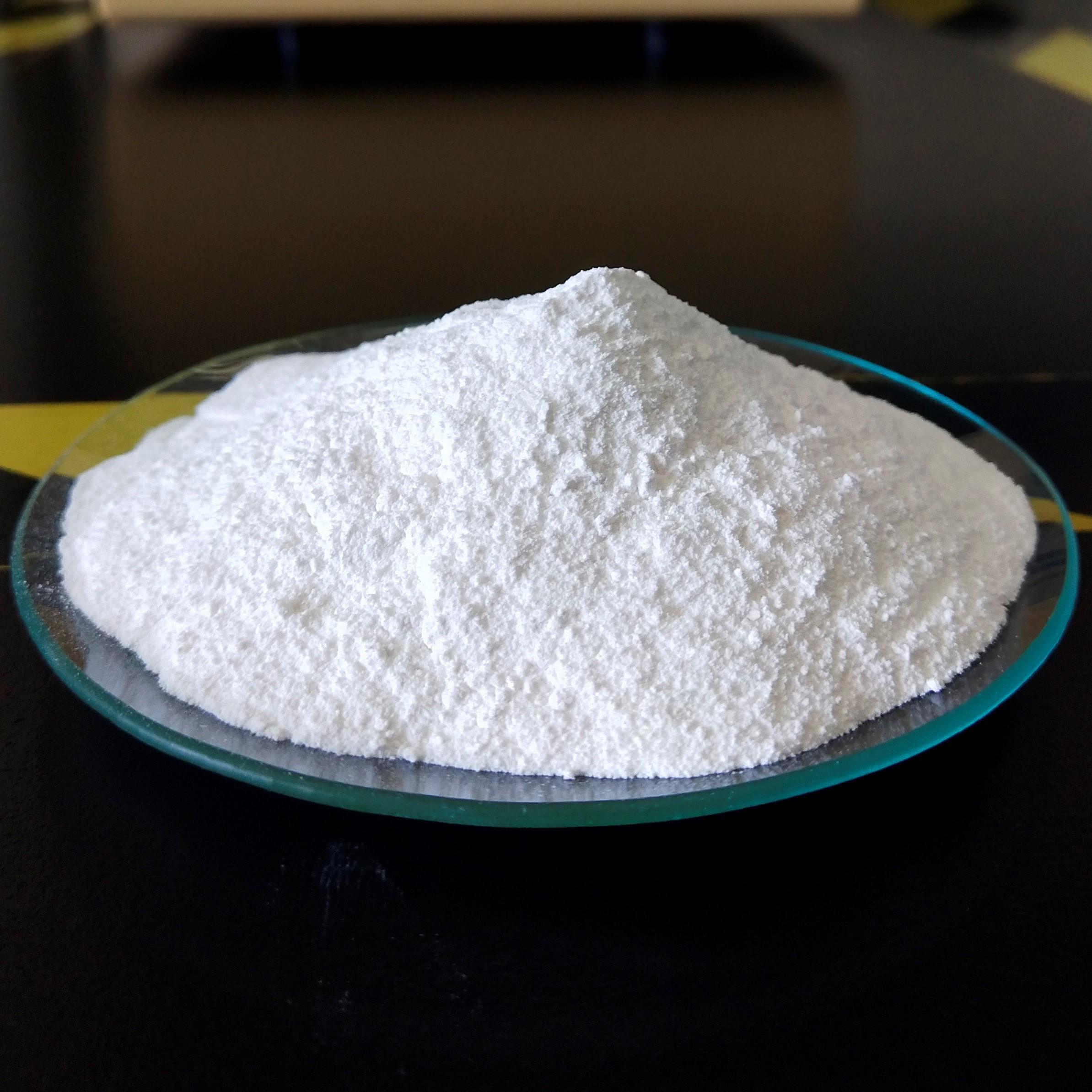

Unlock the Benefits of Customized High-Whiteness Calcium Carbonate for Your Products In today’s competitive marketplace, businesses are constantly searching for innovative materials that can improve product quality, reduce costs, and enhance customer satisfaction. One such compound that has gained significant traction across various industries is **customized high-whiteness calcium carbonate**.

Unlock the Benefits of Customized High-Whiteness Calcium Carbonate for Your Products

In today’s competitive marketplace, businesses are constantly searching for innovative materials that can improve product quality, reduce costs, and enhance customer satisfaction. One such compound that has gained significant traction across various industries is **customized high-whiteness calcium carbonate**. This article delves into the numerous advantages of incorporating this versatile mineral into your products, highlighting its unique properties, applications, and the impact it can have on your bottom line.

Table of Contents

- 1. Introduction to High-Whiteness Calcium Carbonate

- 2. Properties of Customized High-Whiteness Calcium Carbonate

- 3. Benefits of Using High-Whiteness Calcium Carbonate

- 4. Applications in Various Industries

- 5. Choosing the Right Customized High-Whiteness Calcium Carbonate

- 6. The Production Process of Customized Calcium Carbonate

- 7. Sustainability Aspects of Calcium Carbonate

- 8. Conclusion

- 9. FAQs

1. Introduction to High-Whiteness Calcium Carbonate

Calcium carbonate (CaCO3) is a naturally occurring mineral found in rocks, shells, and other geological formations. It serves as a fundamental compound in various industries, from construction to food production. **High-whiteness calcium carbonate**, in particular, is specially processed to achieve superior whiteness and purity, making it an ideal choice for applications requiring high aesthetic and functional standards.

What Makes High-Whiteness Calcium Carbonate Different?

The **customized high-whiteness calcium carbonate** is not merely a standard grade of calcium carbonate. It undergoes specific processing techniques that enhance its whiteness, fineness, and purity levels, which can be tailored according to the unique needs of different industries. This ensures that manufacturers can achieve optimal results in their products.

2. Properties of Customized High-Whiteness Calcium Carbonate

Understanding the properties of **customized high-whiteness calcium carbonate** is crucial for businesses looking to leverage its benefits. Here are some of the key attributes:

1. Superior Whiteness

One of the most notable properties of this compound is its **high brightness and whiteness**, which not only enhances product visual appeal but also ensures color consistency across batches.

2. Fine Particle Size

The **fine particle size distribution** allows for better dispersion in various mediums, improving the overall performance of products. This property is particularly advantageous in paint and coating applications.

3. Chemical Purity

Customized high-whiteness calcium carbonate boasts **high chemical purity**, which minimizes impurities that could affect the quality and stability of end products.

4. Low Oil Absorption

Its low oil absorption rate contributes to the cost-effectiveness of formulations, allowing manufacturers to use less resin or binder while maintaining performance.

3. Benefits of Using High-Whiteness Calcium Carbonate

Incorporating **high-whiteness calcium carbonate** into your products can lead to several advantages:

1. Enhanced Aesthetic Qualities

For industries such as paints, coatings, and plastics, the **whiteness** and *brightness* provided by this compound can significantly enhance the visual appeal of products, attracting consumers and ultimately boosting sales.

2. Improved Product Performance

The **fine particle size** and consistency of high-whiteness calcium carbonate contribute to better functionality in various applications, improving durability and performance.

3. Cost Efficiency

By using high-whiteness calcium carbonate as a filler, manufacturers can reduce the amount of more expensive raw materials needed, thus enhancing overall production efficiency and lowering costs.

4. Versatility Across Applications

This compound can be utilized in a wide array of products, making it a versatile choice for manufacturers across different sectors.

4. Applications in Various Industries

The versatility of customized high-whiteness calcium carbonate allows it to be employed in multiple industries:

1. Paints and Coatings

The **high brightness** and *low oil absorption* of calcium carbonate make it an excellent additive for paints and coatings, improving opacity and coverage while maintaining a cost-effective formulation.

2. Plastics and Polymers

In plastic manufacturing, high-whiteness calcium carbonate serves as a filler that enhances properties like rigidity, impact resistance, and thermal stability.

3. Paper Production

Used in the paper industry, this compound improves the **whiteness** and *smoothness* of paper, making it ideal for high-quality printing applications.

4. Rubber Industry

High-whiteness calcium carbonate is also valuable in rubber manufacturing, where it enhances strength and durability without compromising flexibility.

5. Food and Pharmaceuticals

In food and pharmaceutical applications, calcium carbonate serves as a **calcium supplement** and can act as a colorant, ensuring product integrity and safety.

5. Choosing the Right Customized High-Whiteness Calcium Carbonate

Selecting the appropriate grade of customized high-whiteness calcium carbonate involves several considerations:

1. Specifications

Understand the **whiteness**, *purity*, and **particle size** requirements specific to your application. Work closely with suppliers to obtain samples and test their suitability for your needs.

2. Supplier Reliability

Choose suppliers with a proven track record in delivering high-quality products consistently. This can significantly impact your production process and end product quality.

3. Cost-Effectiveness

Evaluate the pricing structure to ensure that you are getting the best value for your investment without compromising on quality.

4. Technical Support

Reliable suppliers often provide technical support and guidance, assisting in the integration of high-whiteness calcium carbonate into your processes.

6. The Production Process of Customized Calcium Carbonate

The production of customized high-whiteness calcium carbonate involves several key steps:

1. Extraction

The process begins with the extraction of raw calcium carbonate from natural sources, followed by a rigorous purification process to achieve the desired levels of purity and whiteness.

2. Milling and Classification

The extracted material is then milled to achieve fine particle size and subsequently classified to ensure uniformity in the final product.

3. Surface Treatment

In many cases, **surface treatment** is applied to enhance the performance characteristics of the calcium carbonate, such as its dispersion in various mediums.

4. Quality Control

Throughout the production process, strict quality control measures are implemented to ensure that the final product meets all specifications and standards.

7. Sustainability Aspects of Calcium Carbonate

As industries increasingly focus on sustainability, high-whiteness calcium carbonate presents an environmentally friendly option:

1. Abundance

Calcium carbonate is abundant and widely available, reducing the environmental impact associated with sourcing and transportation.

2. Biodegradability

As a naturally occurring mineral, calcium carbonate is biodegradable, making it a sustainable choice for various applications.

3. Carbon Sequestration

Utilizing calcium carbonate in industrial processes can contribute to carbon sequestration, aiding in efforts to mitigate climate change.

8. Conclusion

Incorporating **customized high-whiteness calcium carbonate** into your products can unlock a multitude of benefits, enhancing aesthetic qualities, improving performance, and offering cost efficiencies across various industries. By understanding its unique properties and applications, businesses can capitalize on this valuable mineral to stay competitive in today's market. As industries continue to evolve, high-whiteness calcium carbonate will undoubtedly play a pivotal role in driving innovation and sustainability.

9. FAQs

1. What is high-whiteness calcium carbonate?

High-whiteness calcium carbonate is a refined form of calcium carbonate that has undergone processing to enhance its whiteness, purity, and particle size, making it suitable for various industrial applications.

2. How is customized high-whiteness calcium carbonate produced?

The production involves extracting raw calcium carbonate, purifying it, milling it to a fine particle size, and applying surface treatments to enhance its properties.

3. Which industries benefit from high-whiteness calcium carbonate?

Industries such as paints and coatings, plastics, paper, rubber, and food production significantly benefit from using high-whiteness calcium carbonate.

4. Can high-whiteness calcium carbonate improve product performance?

Yes, its fine particle size and chemical purity contribute to enhanced product performance, including durability, opacity, and overall functionality.

5. Is high-whiteness calcium carbonate environmentally friendly?

Yes, it is abundant, biodegradable, and can contribute to carbon sequestration, making it a sustainable choice for various applications.

customized high-whiteness calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.