24

2025

-

04

Innovative Formulations Utilizing Premium Colloidal Nano Calcium Carbonate

Introduction to Colloidal Nano Calcium Carbonate Colloidal nano calcium carbonate (CNC) has emerged as a groundbreaking material in the field of pigments and dyes. Its unique properties and versatility make it a paramount choice for industries seeking innovative formulations. In this article, we will delve deep into what colloidal nano calcium carbonate is, its benefits, and its various applicatio

Introduction to Colloidal Nano Calcium Carbonate

Colloidal nano calcium carbonate (CNC) has emerged as a groundbreaking material in the field of pigments and dyes. Its unique properties and versatility make it a paramount choice for industries seeking innovative formulations. In this article, we will delve deep into what colloidal nano calcium carbonate is, its benefits, and its various applications across different industries.

Understanding Colloidal Nano Calcium Carbonate

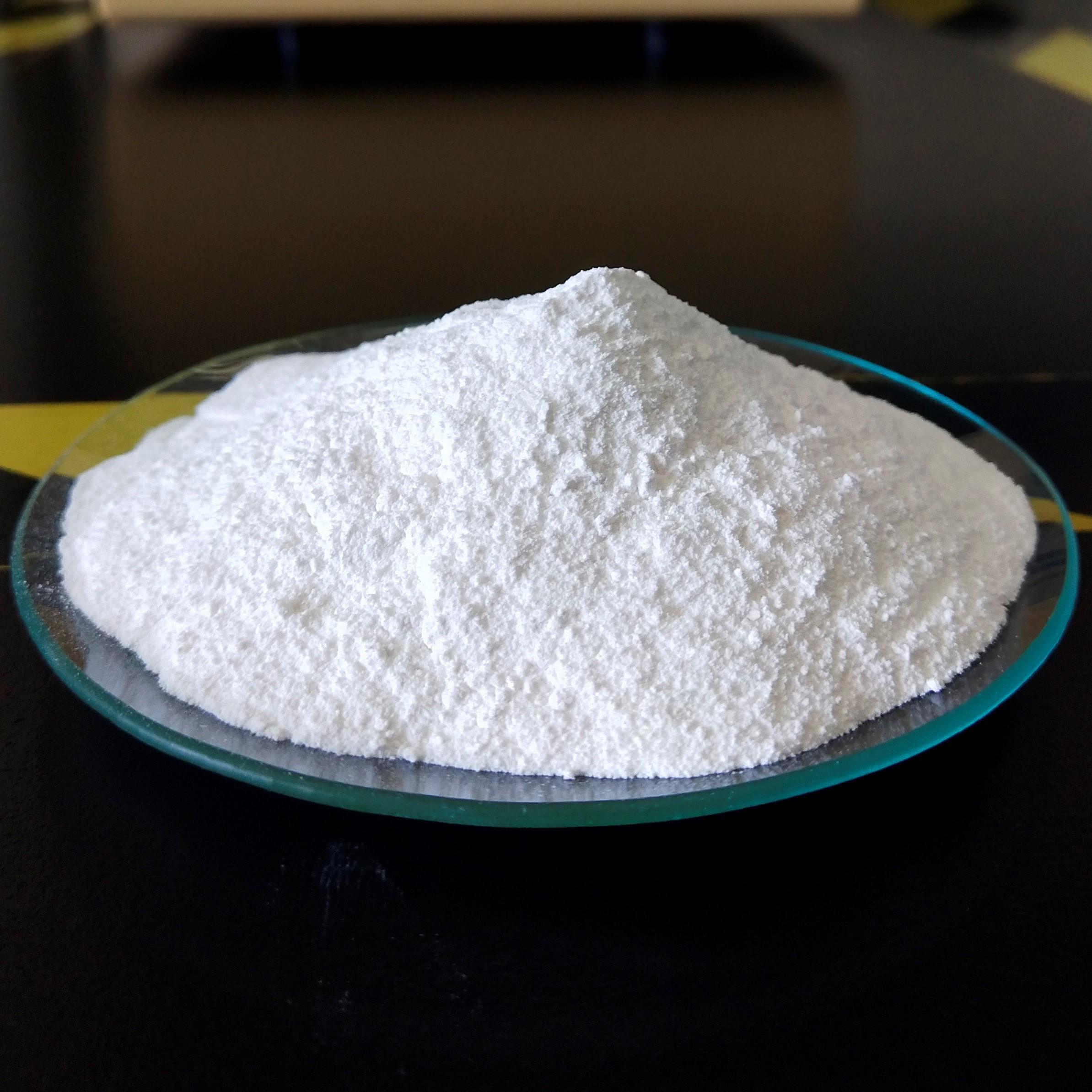

Colloidal nano calcium carbonate is an ultrafine powder that possesses a high surface area and exceptional dispersion characteristics. This compound is synthesized through advanced precipitation techniques, resulting in nanoparticles that can be easily suspended in liquids.

The Unique Properties of Colloidal Nano Calcium Carbonate

1. **High Surface Area**: The nanoscale size of CNC provides an increased surface area that facilitates better interaction with other materials.

2. **Enhanced Dispersion**: Due to its small particle size, CNC can be uniformly dispersed in various media, which is vital for achieving consistent performance in formulations.

3. **Eco-Friendliness**: As a naturally occurring mineral, calcium carbonate is biodegradable and non-toxic, making it an environmentally friendly choice for formulations.

4. **Cost-Effectiveness**: The production of colloidal nano calcium carbonate is relatively low-cost, providing a competitive advantage for manufacturers.

Applications in the Chemical Industry

Colloidal nano calcium carbonate finds extensive use in the chemical industry. Its unique properties enable it to serve various purposes, including as a pigment, filler, and stabilizer.

1. Pigment Applications

In the pigment industry, CNC can enhance the opacity and whiteness of paints and coatings. Its fine particle size allows for a smooth finish, making it ideal for high-quality applications. Additionally, it can improve the durability and weather resistance of coatings, making it a preferred choice for outdoor products.

2. Filler in Plastics and Polymers

CNC serves as an effective filler in plastics and polymers, enhancing their mechanical properties without compromising flexibility. By incorporating colloidal nano calcium carbonate, manufacturers can reduce production costs while improving the overall strength of the final product.

3. Stabilizer in Emulsions

In the formulation of emulsions, colloidal nano calcium carbonate aids in stabilizing the mixture, preventing separation of components. This property is especially beneficial in food products and cosmetics, where consistency is crucial for consumer satisfaction.

Innovative Formulations with Colloidal Nano Calcium Carbonate

The adaptability of colloidal nano calcium carbonate allows for innovative formulations that cater to specific industry needs. Below, we explore some of these formulations in detail.

1. High-Performance Coatings

By incorporating CNC into coatings, manufacturers can achieve superior performance in terms of scratch resistance and color retention. This results in a product that not only looks good but also lasts longer.

2. Sustainable Construction Materials

In the construction industry, colloidal nano calcium carbonate is being used to develop sustainable building materials. Its ability to enhance the mechanical properties of concrete makes it an attractive option for eco-friendly construction practices.

3. Advanced Polymer Composites

Manufacturers are utilizing CNC in the creation of advanced polymer composites. These composites exhibit enhanced strength, durability, and thermal stability, catering to the demands of modern engineering applications.

Environmental Benefits of Colloidal Nano Calcium Carbonate

The use of colloidal nano calcium carbonate is not only beneficial for manufacturers but also for the environment.

1. Reduced Carbon Footprint

Using CNC in formulations can lead to a reduced carbon footprint due to lower energy consumption during production and application.

2. Biodegradability

As a natural miner, CNC is biodegradable and poses minimal environmental hazards compared to synthetic additives. This characteristic aligns with the growing trend toward sustainable and eco-friendly products.

Challenges and Considerations

While colloidal nano calcium carbonate presents numerous advantages, there are challenges that manufacturers must consider.

1. Storage and Handling

Due to its fine particle size, CNC can be prone to clumping and settling if not stored correctly. Proper handling and storage practices are essential to maintain its efficacy.

2. Compatibility with Other Materials

It is crucial to test CNC’s compatibility with other materials in formulations to avoid adverse reactions, which can affect product quality.

FAQs about Colloidal Nano Calcium Carbonate

1. What is colloidal nano calcium carbonate?

Colloidal nano calcium carbonate is an ultrafine powder with unique properties that enhance its performance in various applications, including as a pigment, filler, and stabilizer.

2. How is colloidal nano calcium carbonate produced?

It is produced through advanced precipitation techniques that create nanoparticles with a high surface area, ideal for suspension in liquids.

3. What are the benefits of using colloidal nano calcium carbonate in formulations?

The benefits include enhanced dispersion, increased opacity, improved mechanical properties, and eco-friendliness.

4. In which industries is colloidal nano calcium carbonate commonly used?

It is widely utilized in the coatings, plastics, construction, and cosmetic industries.

5. Are there any environmental concerns associated with colloidal nano calcium carbonate?

No, colloidal nano calcium carbonate is biodegradable and poses minimal environmental risks compared to synthetic additives.

Conclusion

In conclusion, **colloidal nano calcium carbonate** stands out as a transformative material in diverse industries. Its unique properties, such as high surface area, enhanced dispersion, and environmental friendliness, enable innovative formulations that meet the growing demand for high-performance and sustainable products. As industries continue to evolve, the adoption of colloidal nano calcium carbonate will undoubtedly play a pivotal role in shaping the future of formulations, driving innovation, and promoting sustainability. By embracing this remarkable compound, manufacturers can stay ahead in the competitive market while contributing to a greener planet.

best colloidal nano calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.