22

2025

-

04

Unlocking the Benefits of Ultrafine Calcium Carbonate in Industrial Applications

Unlocking the Benefits of Ultrafine Calcium Carbonate in Industrial Applications Table of Contents 1. Introduction to Ultrafine Calcium Carbonate 2. What is Ultrafine Calcium Carbonate? 3. Production Process of Ultrafine Calcium Carbonate 4. Applications of Ultrafine Calcium Carbonate in Industries 4.1 Ultrafine Calcium Carbonate in Paints and Coatings

Unlocking the Benefits of Ultrafine Calcium Carbonate in Industrial Applications

Table of Contents

- 1. Introduction to Ultrafine Calcium Carbonate

- 2. What is Ultrafine Calcium Carbonate?

- 3. Production Process of Ultrafine Calcium Carbonate

- 4. Applications of Ultrafine Calcium Carbonate in Industries

- 4.1 Ultrafine Calcium Carbonate in Paints and Coatings

- 4.2 Ultrafine Calcium Carbonate in Plastics

- 4.3 Ultrafine Calcium Carbonate in Pharmaceuticals

- 4.4 Ultrafine Calcium Carbonate in Food and Beverages

- 5. Advantages of Ultrafine Calcium Carbonate

- 6. Environmental Impact of Ultrafine Calcium Carbonate

- 7. Future Trends in Ultrafine Calcium Carbonate Usage

- 8. Conclusion

- 9. FAQs

1. Introduction to Ultrafine Calcium Carbonate

Ultrafine calcium carbonate (UCC) has emerged as a transformative material in numerous industrial applications. With its unique properties, UCC contributes significantly to the quality and performance of products across various sectors, including paints, plastics, pharmaceuticals, and food. This article delves into the benefits, production processes, applications, and future trends of UCC, providing a comprehensive understanding of its role in enhancing industrial efficiency and sustainability.

2. What is Ultrafine Calcium Carbonate?

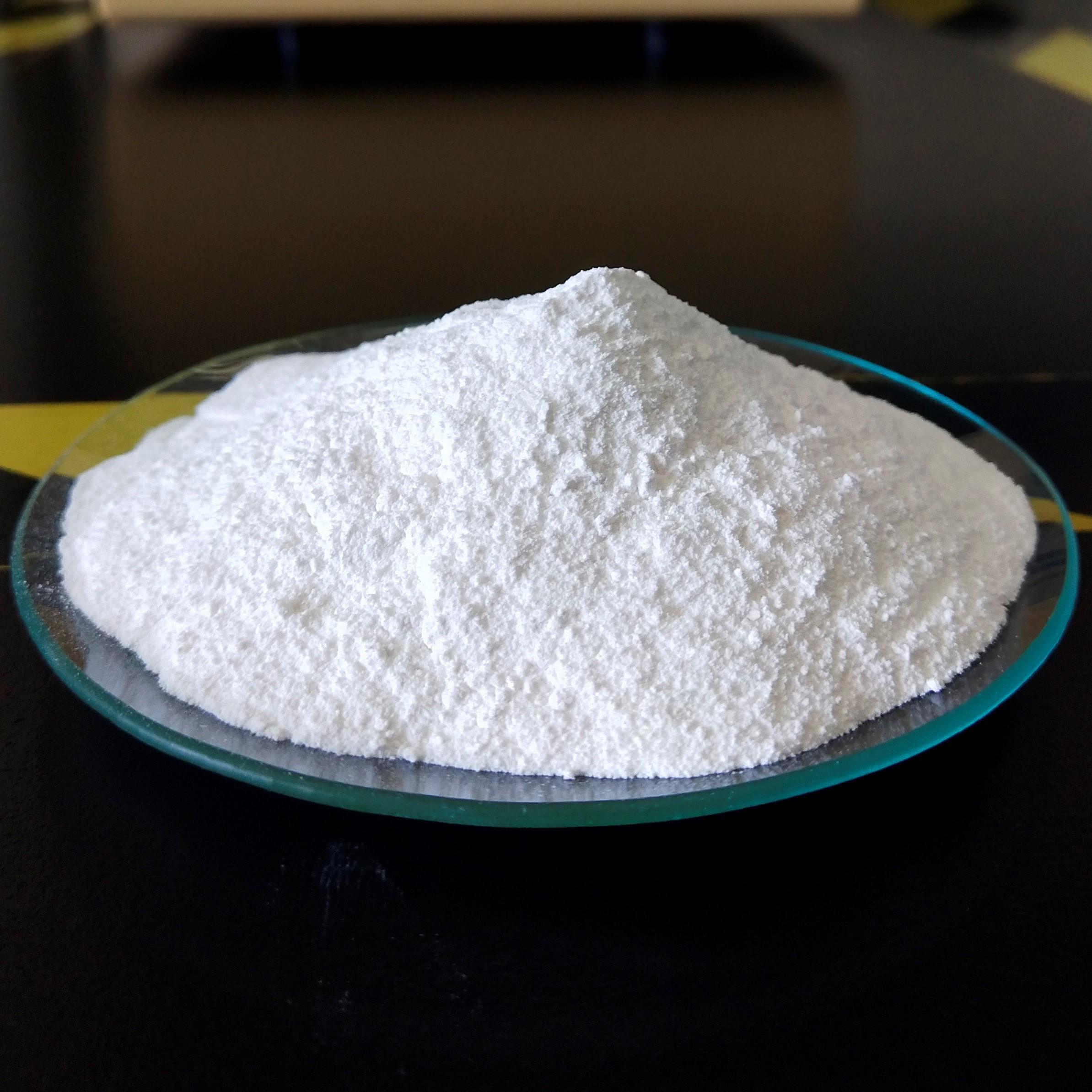

Ultrafine calcium carbonate is a fine-grade calcium carbonate with particle sizes typically ranging from 1 to 5 micrometers. Its ultra-fine nature grants it exceptional surface area, which enhances its reactivity and performance in various applications. UCC is derived from high-purity limestone and is processed to achieve its specified fineness, ensuring that it meets industrial standards.

3. Production Process of Ultrafine Calcium Carbonate

The production of ultrafine calcium carbonate involves several critical steps:

3.1 Mining and Crushing

The process begins with the extraction of high-purity limestone from quarries. The limestone is then crushed into smaller pieces to facilitate further processing.

3.2 Grinding and Milling

The crushed limestone undergoes grinding and milling to achieve the desired particle size. Various milling techniques, such as ball milling, are employed to produce ultrafine particles.

3.3 Classification

Following milling, the particles are classified based on size. This step ensures that only particles within the desired range are selected for further processing.

3.4 Surface Modification

To enhance the properties of UCC, surface modification techniques may be applied. This process increases the compatibility of UCC with other materials in industrial applications.

3.5 Quality Control

Finally, rigorous quality control measures are undertaken to ensure that the UCC meets the required specifications before it is packaged and distributed.

4. Applications of Ultrafine Calcium Carbonate in Industries

Ultrafine calcium carbonate is utilized across various industries due to its versatile properties. Below are some of the key applications:

4.1 Ultrafine Calcium Carbonate in Paints and Coatings

In the paint and coatings industry, UCC serves as a filler and a pigment. Its fine particle size contributes to improved opacity and gloss, enhancing the aesthetic appeal of paints. Additionally, UCC improves the mechanical strength and durability of coatings, making them more resistant to weathering and wear.

4.2 Ultrafine Calcium Carbonate in Plastics

The plastic industry benefits from UCC as a performance enhancer. When incorporated into plastic formulations, UCC improves tensile strength, impact resistance, and thermal stability. It also serves as a cost-effective filler, reducing the overall material costs without compromising product quality.

4.3 Ultrafine Calcium Carbonate in Pharmaceuticals

In the pharmaceutical sector, UCC is used as an excipient in drug formulations. Its high purity and fine particle size make it an ideal candidate for tablets and powders, aiding in drug delivery and improving bioavailability. UCC also acts as a buffering agent, helping to regulate pH levels in formulations.

4.4 Ultrafine Calcium Carbonate in Food and Beverages

UCC is recognized for its safety and functionality in food applications. It is used as a food additive, acting as a calcium supplement and anti-caking agent. In beverages, UCC helps to stabilize emulsions and improve mouthfeel, enhancing the consumer experience.

5. Advantages of Ultrafine Calcium Carbonate

The incorporation of ultrafine calcium carbonate into industrial processes carries numerous advantages:

5.1 Enhanced Product Performance

UCC improves the mechanical and aesthetic properties of products across various industries, leading to higher customer satisfaction.

5.2 Cost-Effectiveness

By serving as a filler material, UCC reduces the cost of raw materials, helping manufacturers achieve higher profit margins.

5.3 Environmental Sustainability

UCC production can be more environmentally sustainable compared to other materials. Its use in products often leads to lower energy consumption during processing.

5.4 Versatility

The wide range of applications for UCC demonstrates its versatility, making it a valuable material for various industries.

6. Environmental Impact of Ultrafine Calcium Carbonate

The environmental impact of ultrafine calcium carbonate is an important consideration in its production and application.

6.1 Sustainable Sourcing

The sourcing of high-purity limestone for UCC is typically conducted with sustainability in mind. Many manufacturers are adopting environmentally responsible mining practices to minimize ecological disruption.

6.2 Reduced Carbon Footprint

By substituting UCC for more energy-intensive materials, industries can significantly reduce their overall carbon footprint, contributing to global sustainability efforts.

6.3 Recycling and Reusability

UCC can often be recycled and reused in various applications, further enhancing its sustainability profile.

7. Future Trends in Ultrafine Calcium Carbonate Usage

As industries continue to evolve, the role of ultrafine calcium carbonate is expected to expand. Key future trends include:

7.1 Increasing Demand in Green Technologies

With a growing emphasis on sustainability, the demand for UCC in green technologies, such as biodegradable plastics and eco-friendly paints, is on the rise.

7.2 Innovations in Production Techniques

Advancements in production techniques will likely lead to even finer grades of UCC, further enhancing its applications and performance.

7.3 Expanding Applications

New applications in emerging industries, such as renewable energy and advanced materials, will broaden the scope of UCC usage, making it an integral component of future innovations.

8. Conclusion

Ultrafine calcium carbonate stands out as a pivotal material in industrial applications, offering numerous benefits ranging from enhanced product performance to environmental sustainability. As industries continue to explore the capabilities of UCC, its role in improving efficiency and reducing costs will only become more pronounced. By harnessing the advantages of ultrafine calcium carbonate, manufacturers can not only elevate their product quality but also contribute to a more sustainable industrial future.

9. FAQs

What is ultrafine calcium carbonate used for?

Ultrafine calcium carbonate is used in various applications, including paints, plastics, pharmaceuticals, and food, due to its fine particle size and unique properties.

How is ultrafine calcium carbonate produced?

UCC is produced through a series of steps including mining, crushing, grinding, classification, surface modification, and quality control.

What are the benefits of using ultrafine calcium carbonate?

The benefits include enhanced product performance, cost-effectiveness, environmental sustainability, and versatility across various industrial applications.

Is ultrafine calcium carbonate environmentally friendly?

Yes, UCC can be produced sustainably, and its use can help reduce the carbon footprint of various products.

What industries benefit from ultrafine calcium carbonate?

Industries such as paints and coatings, plastics, pharmaceuticals, and food and beverages benefit significantly from the use of ultrafine calcium carbonate.

ultrafine calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.