18

2025

-

04

Exploring the Benefits of Ultrafine Calcium Carbonate in Industrial Applications

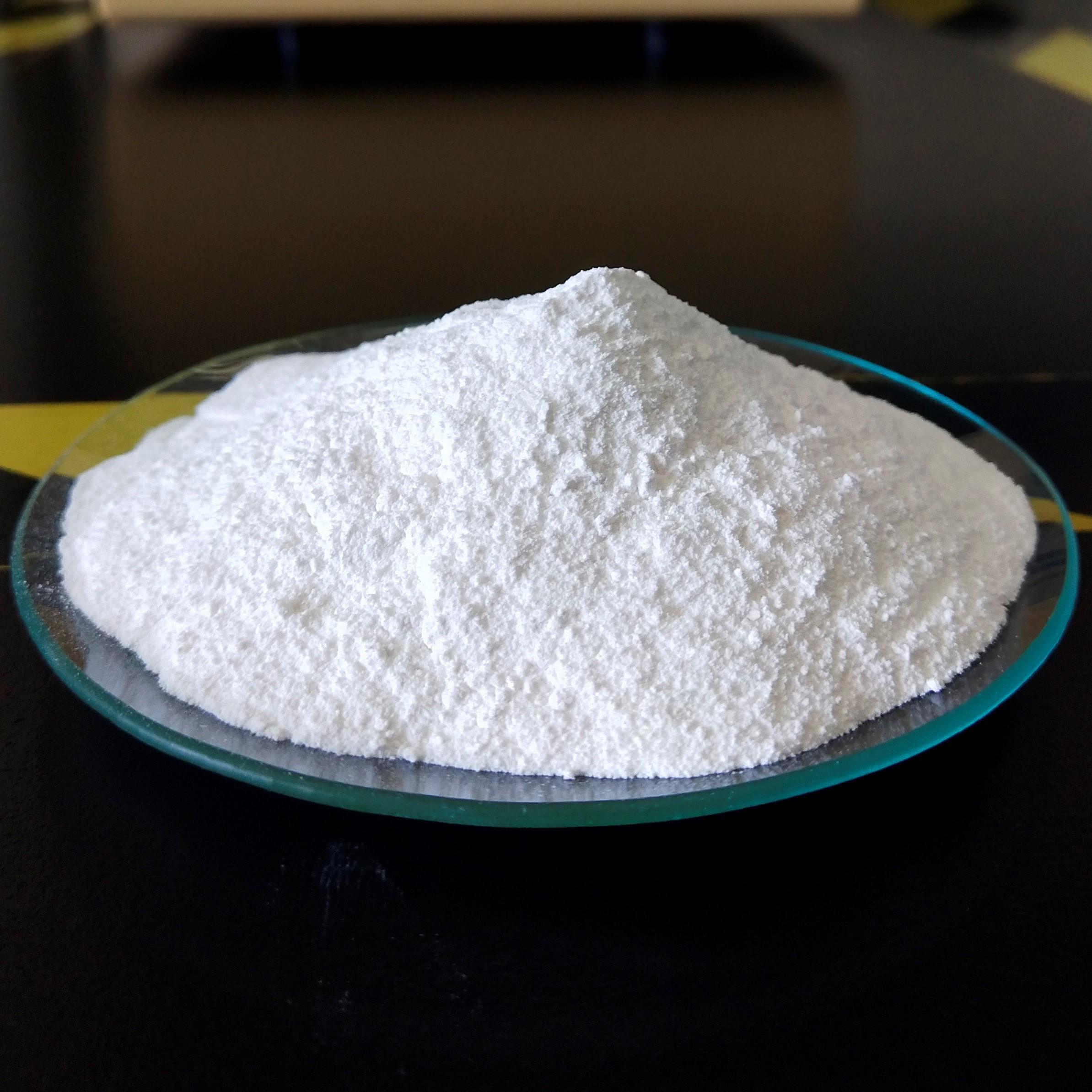

Exploring the Benefits of Ultrafine Calcium Carbonate in Industrial Applications Calcium carbonate, a naturally occurring compound, has been a vital ingredient in various industrial applications for decades. Among its many forms, **ultrafine calcium carbonate (UFCC)** stands out as a game-changer. As industries evolve and seek innovative solutions to enhance product performance, the demand for ult

Exploring the Benefits of Ultrafine Calcium Carbonate in Industrial Applications

Calcium carbonate, a naturally occurring compound, has been a vital ingredient in various industrial applications for decades. Among its many forms, **ultrafine calcium carbonate (UFCC)** stands out as a game-changer. As industries evolve and seek innovative solutions to enhance product performance, the demand for ultrafine calcium carbonate continues to grow. This article explores the multiple benefits of ultrafine calcium carbonate, its industrial applications, production methods, and its significant role in enhancing product quality and sustainability.

Table of Contents

1. What is Ultrafine Calcium Carbonate?

2. Key Properties of Ultrafine Calcium Carbonate

3. Industrial Applications of Ultrafine Calcium Carbonate

- 3.1 3.1 Plastics and Polymers

- 3.2 3.2 Paints and Coatings

- 3.3 3.3 Rubber Industry

- 3.4 3.4 Pharmaceuticals and Food Industry

4. Benefits of Ultrafine Calcium Carbonate in Industrial Applications

- 4.1 4.1 Cost-Effectiveness

- 4.2 4.2 Enhanced Performance

- 4.3 4.3 Environmental Benefits

5. Production Methods of Ultrafine Calcium Carbonate

6. The Future of Ultrafine Calcium Carbonate

7. Frequently Asked Questions

8. Conclusion

What is Ultrafine Calcium Carbonate?

Ultrafine calcium carbonate refers to particles of calcium carbonate that have been processed to achieve a very small size, typically under 5 micrometers. This fine-grade material exhibits unique properties that significantly enhance its performance in various applications. The production of ultrafine calcium carbonate involves advanced techniques such as **precipitation, milling, and classification**, ensuring uniform particle size and high purity.

The high surface area and unique particle characteristics of ultrafine calcium carbonate allow it to function effectively as a filler, pigment, and functional additive in numerous industrial products.

Key Properties of Ultrafine Calcium Carbonate

The distinctive properties of ultrafine calcium carbonate make it an invaluable resource across various industries. Some of the key properties include:

- **High Purity**: Ultrafine calcium carbonate is produced with minimal impurities, ensuring it meets stringent quality standards.

- **Particle Size Distribution**: The controlled particle size enhances its performance as a filler, providing improved mechanical and optical properties.

- **Chemical Stability**: It maintains its properties under various environmental conditions, making it suitable for diverse applications.

- **Versatility**: Its ability to blend seamlessly with other materials contributes to its widespread use in numerous formulations.

Industrial Applications of Ultrafine Calcium Carbonate

Ultrafine calcium carbonate has found applications across multiple industries due to its versatility and beneficial properties. Here, we delve into some of the primary sectors where ultrafine calcium carbonate plays a crucial role.

3.1 Plastics and Polymers

In the **plastics and polymers** industry, ultrafine calcium carbonate serves as an effective filler, enhancing the mechanical strength and durability of plastic products. By incorporating ultrafine calcium carbonate, manufacturers can achieve:

- **Improved Dimensional Stability**: It helps minimize shrinkage and warping, ensuring the final product maintains its shape.

- **Cost Reduction**: By replacing more expensive materials, ultrafine calcium carbonate reduces production costs while maintaining quality.

- **Enhanced Surface Finish**: It contributes to a smoother surface texture, improving the aesthetic appeal of plastic products.

3.2 Paints and Coatings

The **paints and coatings** industry benefits significantly from ultrafine calcium carbonate. Its properties enhance the quality and performance of paints, including:

- **Increased Opacity**: Ultrafine calcium carbonate enhances pigmentation, providing better coverage and color retention.

- **Improved Gloss**: It helps achieve a glossy finish while maintaining the desired texture.

- **Better Flow Properties**: The fine particle size ensures optimal flow during application, reducing the likelihood of defects.

3.3 Rubber Industry

In the **rubber industry**, ultrafine calcium carbonate acts as a reinforcing filler, contributing to the performance and durability of rubber products. Key benefits include:

- **Enhanced Mechanical Properties**: It improves tensile strength and tear resistance, making rubber products more robust.

- **Cost Efficiency**: By partially replacing more expensive fillers, ultrafine calcium carbonate lowers production costs.

- **Processing Improvements**: It facilitates better mixing and processing, resulting in smoother rubber compounds.

3.4 Pharmaceuticals and Food Industry

Ultrafine calcium carbonate also finds applications in the **pharmaceutical and food industry** as a calcium supplement and anticaking agent. Its advantages include:

- **Bioavailability**: It provides an easily absorbed source of calcium, essential for various health applications.

- **Quality Control**: Its purity and consistency make it suitable for use in food and pharmaceutical formulations.

Benefits of Ultrafine Calcium Carbonate in Industrial Applications

Incorporating ultrafine calcium carbonate into industrial processes yields numerous benefits, enhancing product quality, sustainability, and overall performance.

4.1 Cost-Effectiveness

One of the most significant advantages of ultrafine calcium carbonate is its cost-effectiveness. By acting as an alternative to more expensive materials, it helps manufacturers reduce production costs without compromising quality. This makes it an attractive option for businesses looking to optimize their product formulations.

4.2 Enhanced Performance

Ultrafine calcium carbonate enhances the overall performance of various products. Its unique properties contribute to improved mechanical strength, durability, and aesthetic appeal. This enhancement is particularly crucial in competitive markets where product differentiation can lead to increased sales.

4.3 Environmental Benefits

The use of ultrafine calcium carbonate aligns with sustainability goals in various industries. Its natural origin and non-toxic nature make it an environmentally friendly choice. Moreover, by replacing synthetic materials with ultrafine calcium carbonate, companies can reduce their environmental footprint, contributing to a more sustainable manufacturing process.

Production Methods of Ultrafine Calcium Carbonate

The production of ultrafine calcium carbonate involves several advanced methods that ensure high purity and uniform particle size. Common techniques include:

- **Precipitation**: This method involves reacting calcium hydroxide with carbon dioxide to form ultrafine calcium carbonate. The resulting particles are then filtered and dried to achieve the desired size.

- **Mechanical Milling**: Mechanical milling is used to grind larger particles of calcium carbonate into ultrafine sizes, ensuring a consistently fine product.

- **Air Classification**: This technique separates fine particles from coarse ones, allowing for the production of specific particle size distributions.

Each method has its advantages, and the choice often depends on the specific requirements of the end application.

The Future of Ultrafine Calcium Carbonate

As industries continue to evolve, the future of ultrafine calcium carbonate appears promising. With an increasing focus on sustainability and performance enhancement, this versatile material is likely to see expanded applications and innovations. Research and development efforts are underway to explore new formulations and processing techniques, ensuring that ultrafine calcium carbonate remains at the forefront of industrial materials.

Frequently Asked Questions

What industries use ultrafine calcium carbonate?

Ultrafine calcium carbonate is utilized in various industries, including plastics, paints, coatings, rubber, pharmaceuticals, and food production.

How does ultrafine calcium carbonate improve product quality?

It enhances mechanical properties, surface finish, opacity, and overall performance, contributing to higher quality products.

Is ultrafine calcium carbonate environmentally friendly?

Yes, ultrafine calcium carbonate is a natural, non-toxic material that supports sustainability efforts in manufacturing processes.

Can ultrafine calcium carbonate replace other fillers?

Yes, it can effectively replace more expensive fillers while maintaining or enhancing product performance.

What production methods are used for ultrafine calcium carbonate?

Common production methods include precipitation, mechanical milling, and air classification to achieve desired particle sizes and purity.

Conclusion

Ultrafine calcium carbonate is a remarkable material that brings numerous benefits to various industrial applications. Its unique properties, cost-effectiveness, and environmental advantages make it an essential component in the formulations of many products across diverse sectors. As industries continue to innovate and strive for higher quality and sustainability, ultrafine calcium carbonate will undoubtedly play a pivotal role in shaping the future of industrial materials. Whether in plastics, paints, rubber, or pharmaceuticals, the advantages of ultrafine calcium carbonate are clear, making it a valuable asset for manufacturers and formulators alike.

ultrafine calcium carbonate manufacturers

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.