16

2025

-

04

Exploring the Benefits of Quality Ultrafine Nano Calcium Carbonate in Coatings

Exploring the Benefits of Quality Ultrafine Nano Calcium Carbonate in Coatings Table of Contents 1. Introduction to Ultrafine Nano Calcium Carbonate 2. Understanding Ultrafine Nano Calcium Carbonate 3. Key Benefits of Ultrafine Nano Calcium Carbonate in Coatings 3.1 Improved Durability 3.2 Enhanced Adhesion 3.3 Better Coverage and Opacity

Exploring the Benefits of Quality Ultrafine Nano Calcium Carbonate in Coatings

Table of Contents

- 1. Introduction to Ultrafine Nano Calcium Carbonate

- 2. Understanding Ultrafine Nano Calcium Carbonate

- 3. Key Benefits of Ultrafine Nano Calcium Carbonate in Coatings

- 3.1 Improved Durability

- 3.2 Enhanced Adhesion

- 3.3 Better Coverage and Opacity

- 3.4 Cost-Effectiveness

- 4. Applications of Ultrafine Nano Calcium Carbonate in Coatings

- 5. Technical Aspects of Ultrafine Nano Calcium Carbonate

- 6. Importance of Quality in Ultrafine Nano Calcium Carbonate

- 7. Sourcing and Manufacturing of Ultrafine Nano Calcium Carbonate

- 8. Future Trends in Coatings with Ultrafine Nano Calcium Carbonate

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Ultrafine Nano Calcium Carbonate

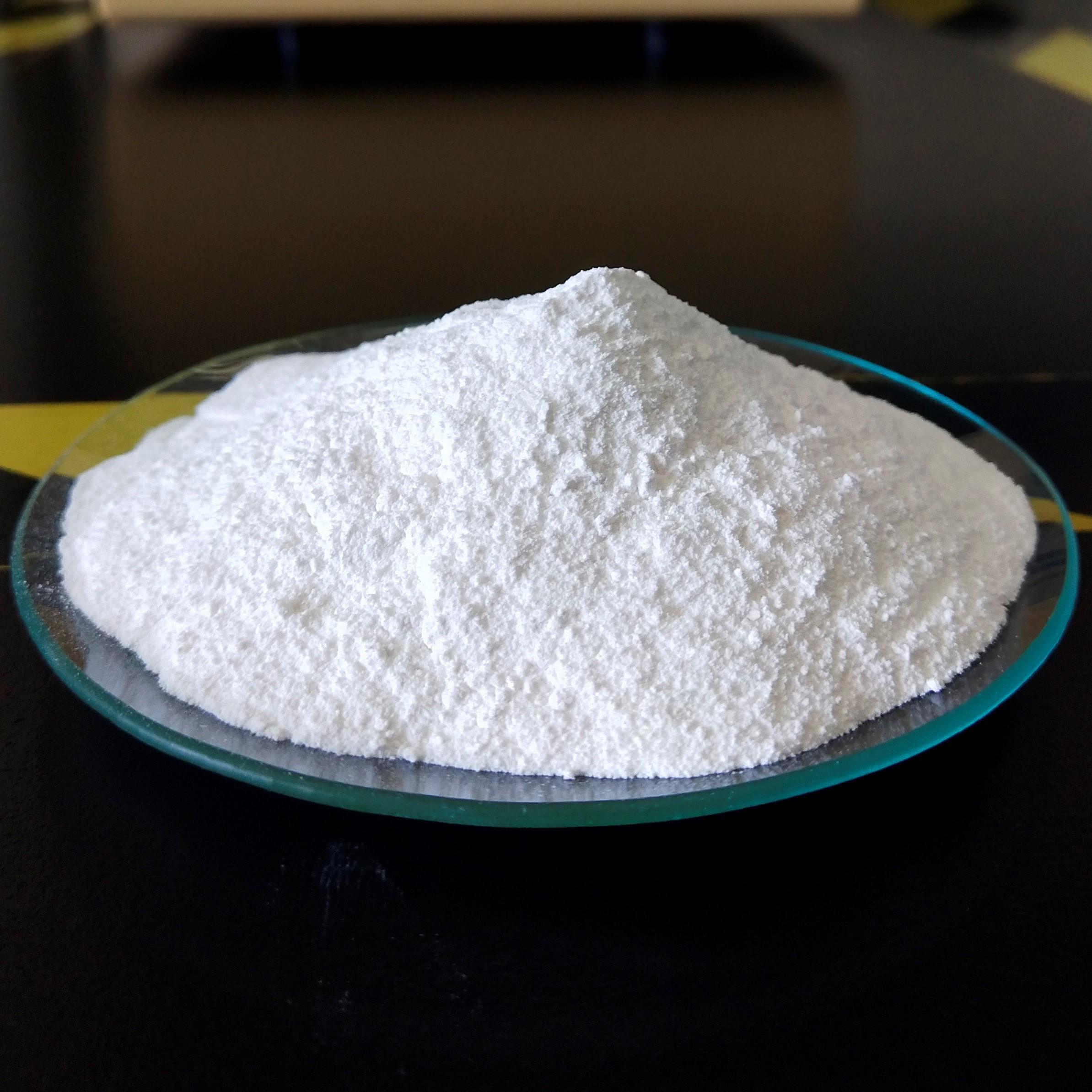

Ultrafine nano calcium carbonate (UCC) has become an essential component in the coatings industry, offering significant advantages over traditional materials. As industries increasingly demand high-performance materials, UCC stands out due to its unique properties. This white powder, with particle sizes in the nanometer range, provides excellent performance characteristics that enhance the quality and longevity of coatings.

2. Understanding Ultrafine Nano Calcium Carbonate

Nano calcium carbonate is produced by various methods, including carbonation, precipitation, and milling. The ultrafine particles provide a higher surface area that contributes to improved interaction within the coating matrix. Understanding the fundamental properties of UCC, including its chemical stability, low abrasiveness, and compatibility with other materials, is crucial for optimizing its use in coatings.

3. Key Benefits of Ultrafine Nano Calcium Carbonate in Coatings

Incorporating UCC into coatings offers multiple technical and economic advantages.

3.1 Improved Durability

One of the primary benefits of UCC is its contribution to improved durability. The nano-sized particles enhance the mechanical strength of the coating, making it resistant to wear, scratching, and environmental factors such as UV radiation and moisture. This increased durability extends the lifecycle of coatings, reducing the need for frequent reapplications.

3.2 Enhanced Adhesion

UCC promotes better adhesion between the coating and substrate. Its fine particle size allows for a more extensive interaction with the surface, resulting in a strong bond. This property is particularly beneficial in applications where coatings are subjected to mechanical stress or adverse environmental conditions.

3.3 Better Coverage and Opacity

Ultrafine calcium carbonate improves the opacity of coatings, providing better coverage with less product. This feature is crucial for manufacturers aiming to achieve high-quality finishes while minimizing material costs. UCC’s superior light scattering properties enhance the visual appeal of coatings, making them more aesthetically pleasing.

3.4 Cost-Effectiveness

Incorporating UCC can lead to significant cost savings for manufacturers. The enhanced performance characteristics allow for the reduction of other, more expensive additives, while the high pigment volume concentration (PVC) ensures that less product is needed for effective application. This dual impact of performance and cost reduction makes UCC an attractive option for manufacturers.

4. Applications of Ultrafine Nano Calcium Carbonate in Coatings

UCC finds extensive applications across various sectors, including:

- **Architectural Coatings**: Used in interior and exterior paints for improved durability and finish.

- **Industrial Coatings**: Enhances the performance of coatings used in automotive, machinery, and appliance sectors.

- **Paper Coatings**: Imparts brightness and opacity, improving printability.

Understanding the specific needs of each application allows manufacturers to optimize formulations for superior performance.

5. Technical Aspects of Ultrafine Nano Calcium Carbonate

The technical properties of UCC, such as particle size distribution, surface area, and purity, significantly influence its performance in coatings. High-quality UCC should have a narrow particle size distribution to ensure consistency in performance. Additionally, the surface treatment of UCC can enhance compatibility with various polymer systems, further improving its utility in diverse coating formulations.

6. Importance of Quality in Ultrafine Nano Calcium Carbonate

Quality assurance in UCC production is critical to ensure optimal performance in coatings. Manufacturers must adhere to strict quality control processes to guarantee that the UCC meets industry standards. This includes regular testing for particle size, purity, and other chemical properties to ensure consistency and reliability in end products.

7. Sourcing and Manufacturing of Ultrafine Nano Calcium Carbonate

When sourcing UCC, manufacturers should prioritize suppliers who utilize advanced production techniques and quality control measures. Understanding the lifecycle of UCC, from raw material sourcing to final processing, can help ensure that the final product meets performance expectations. Sustainable practices in production also play a vital role in today’s environmentally conscious market.

8. Future Trends in Coatings with Ultrafine Nano Calcium Carbonate

The future of the coatings industry with UCC looks promising, with trends leaning towards more sustainable and high-performance materials. Innovations in nanotechnology may lead to new formulations that provide enhanced functionality, such as self-cleaning properties and improved resistance to environmental factors. As industries continue to evolve, UCC will likely play a pivotal role in the development of cutting-edge coatings.

9. Frequently Asked Questions

What is ultrafine nano calcium carbonate?

Ultrafine nano calcium carbonate is a highly refined form of calcium carbonate with particle sizes in the nanometer range, improving various properties in coatings.

What are the benefits of using UCC in coatings?

The benefits include improved durability, enhanced adhesion, better coverage, and cost-effectiveness.

How does UCC enhance coating durability?

UCC increases the mechanical strength of coatings, making them more resistant to wear, UV radiation, and moisture.

What industries benefit from UCC in coatings?

Industries such as construction, automotive, industrial manufacturing, and paper production benefit significantly from UCC.

Why is quality assurance important in UCC production?

Quality assurance ensures that UCC meets industry standards, providing manufacturers with reliable materials for high-performance coatings.

10. Conclusion

The integration of **quality ultrafine nano calcium carbonate** into coatings presents numerous advantages that enhance both performance and economic viability. From improved durability and adhesion to better coverage and cost-effectiveness, UCC stands out as a vital component in modern coating formulations. As industries continue to seek innovative solutions, UCC is likely to play an increasingly crucial role in the development of high-performance coatings, ensuring that products meet the demands of both manufacturers and consumers alike. By focusing on quality sourcing and manufacturing practices, companies can harness the full potential of ultrafine nano calcium carbonate, paving the way for advancements in the coatings industry.

quality ultrafine nano calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.