12

2025

-

04

Unlocking the Benefits of High-Whiteness Calcium Carbonate in Paints

Unlocking the Benefits of High-Whiteness Calcium Carbonate in Paints Introduction: The Role of Calcium Carbonate in Paints In the paint industry, the quest for superior performance and aesthetic qualities drives manufacturers to seek out high-quality raw materials. One such material, **high-whiteness calcium carbonate**, has gained significant attention due to its unique properties and benefit

Unlocking the Benefits of High-Whiteness Calcium Carbonate in Paints

Introduction: The Role of Calcium Carbonate in Paints

In the paint industry, the quest for superior performance and aesthetic qualities drives manufacturers to seek out high-quality raw materials. One such material, **high-whiteness calcium carbonate**, has gained significant attention due to its unique properties and benefits. This article delves into the vital role that calcium carbonate plays in paint formulations, outlining its advantages, applications, and potential for innovation.

Table of Contents

- What is Calcium Carbonate?

- Understanding High-Whiteness Calcium Carbonate

- Key Benefits of High-Whiteness Calcium Carbonate in Paints

- Applications of High-Whiteness Calcium Carbonate in Paint Formulation

- The Impact of High-Whiteness Calcium Carbonate on Paint Quality

- Environmental Considerations and Sustainability

- Choosing the Right Supplier for High-Whiteness Calcium Carbonate

- Frequently Asked Questions

What is Calcium Carbonate?

Calcium carbonate (CaCO3) is a naturally occurring mineral that takes the form of chalk, limestone, and marble. It is widely used in various industries, including construction, pharmaceuticals, and food processing due to its abundance and versatility. In the paint industry, calcium carbonate serves as an important functional filler, offering benefits such as cost-effectiveness, enhanced properties, and improved performance.

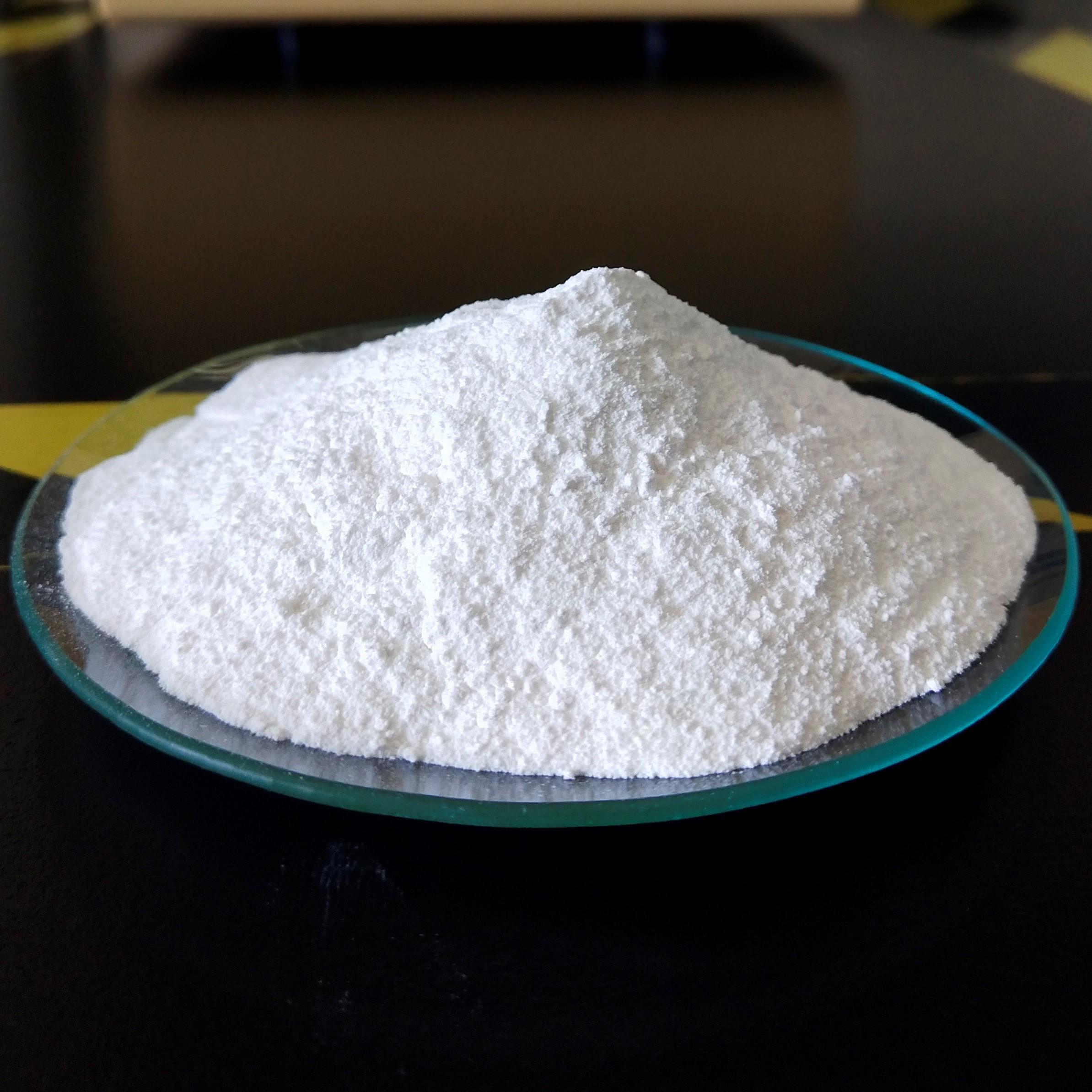

Understanding High-Whiteness Calcium Carbonate

High-whiteness calcium carbonate refers to a specific grade of calcium carbonate that exhibits superior brightness and opacity compared to standard grades. This high whiteness makes it an ideal choice for applications where aesthetic appeal and color fidelity are paramount. Its unique crystalline structure contributes to its light-scattering properties, resulting in excellent coverage and a bright finish in paint formulations.

Production and Processing

The production of high-whiteness calcium carbonate involves meticulous mining and processing techniques. The mineral is extracted from high-purity limestone deposits, followed by careful milling and classification processes to achieve the desired particle size and brightness. This precision ensures that the final product meets industry standards for quality and performance.

Key Benefits of High-Whiteness Calcium Carbonate in Paints

High-whiteness calcium carbonate offers several advantages that enhance paint formulations:

1. Improved Opacity and Coverage

One of the most significant benefits of incorporating high-whiteness calcium carbonate into paint is its ability to improve opacity. Paints formulated with this mineral can cover surfaces more effectively, requiring fewer coats for complete coverage. This not only saves time and labor but also reduces the overall amount of paint needed, making it a cost-effective solution.

2. Enhanced Brightness and Aesthetic Quality

High-whiteness calcium carbonate contributes to the brightness and visual appeal of paints. Its superior light-scattering properties create a vibrant finish, enhancing the colors in the paint and providing a visually striking appearance. This is particularly beneficial in decorative paints where aesthetics play a crucial role.

3. Cost-Effectiveness

By using high-whiteness calcium carbonate as a filler, paint manufacturers can reduce the overall cost of production. This mineral is less expensive than many color pigments and other fillers, allowing for a more economical formulation without compromising quality.

4. Improved Texture and Consistency

High-whiteness calcium carbonate provides a smooth texture to paints, improving their application properties. It helps to achieve a uniform consistency, making the paint easier to spread and apply, whether by brush, roller, or spray gun. This enhances the user experience and results in a more professional finish.

5. Environmental Benefits

As an inorganic mineral, high-whiteness calcium carbonate is non-toxic and environmentally friendly. Its use in paint formulations aligns with the growing demand for sustainable and eco-friendly products. This makes it a favorable choice for manufacturers looking to reduce their environmental footprint while meeting consumer preferences.

Applications of High-Whiteness Calcium Carbonate in Paint Formulation

High-whiteness calcium carbonate finds diverse applications across various types of paints:

1. Architectural Coatings

In architectural coatings, high-whiteness calcium carbonate is utilized to enhance the durability and appearance of exterior and interior paints. Its excellent opacity and brightness contribute to the longevity and visual appeal of buildings, making it a preferred choice among architects and builders.

2. Industrial Coatings

Industrial coatings, such as those used in machinery and equipment, benefit from the abrasion resistance and strength imparted by high-whiteness calcium carbonate. The mineral also helps to reduce production costs, critical in competitive industrial markets.

3. Automotive Paints

In automotive paints, high-whiteness calcium carbonate is used to achieve vibrant colors and enhanced surface finishes. Its contribution to the paint's texture and appearance is vital in the automotive industry, where aesthetics and performance are paramount.

The Impact of High-Whiteness Calcium Carbonate on Paint Quality

The incorporation of high-whiteness calcium carbonate can significantly elevate the overall quality of paint products.

1. Durability and Weather Resistance

Paints formulated with high-whiteness calcium carbonate exhibit improved weather resistance and durability. The mineral enhances the paint's ability to withstand exposure to sunlight, moisture, and varying temperatures, making it ideal for outdoor applications.

2. Enhanced Application Properties

By improving the paint's viscosity and flow properties, high-whiteness calcium carbonate ensures smooth application and prevents issues such as sagging or dripping. This results in a more professional finish and reduces the likelihood of imperfections during application.

Environmental Considerations and Sustainability

Sustainability is becoming increasingly important in the paint industry. High-whiteness calcium carbonate is not only an effective filler but also an environmentally friendly option. Its natural origin and non-toxic properties align with the demand for eco-friendly products, allowing manufacturers to appeal to environmentally conscious consumers.

Choosing the Right Supplier for High-Whiteness Calcium Carbonate

Selecting a reliable supplier of high-whiteness calcium carbonate is crucial for ensuring consistent quality and performance. Consider the following factors when choosing a supplier:

1. Quality Standards

Ensure that the supplier adheres to stringent quality control processes and industry standards. This guarantees that the calcium carbonate meets the specific requirements for your paint formulations.

2. Technical Support

A good supplier should offer technical support and guidance on the best practices for using high-whiteness calcium carbonate in paint formulations. This can help manufacturers optimize their processes and improve product quality.

3. Pricing and Availability

Compare pricing and availability from multiple suppliers to ensure competitive rates and consistent supply. This is essential for maintaining production schedules and managing costs effectively.

Frequently Asked Questions

1. What is the difference between standard and high-whiteness calcium carbonate?

High-whiteness calcium carbonate has superior brightness and opacity compared to standard grades, making it ideal for applications demanding aesthetic quality.

2. How does high-whiteness calcium carbonate improve paint coverage?

Its unique light-scattering properties enhance opacity, allowing for better coverage with fewer layers of paint.

3. Is high-whiteness calcium carbonate environmentally friendly?

Yes, high-whiteness calcium carbonate is non-toxic and derived from natural sources, making it an environmentally safe choice for paint formulations.

4. Can high-whiteness calcium carbonate replace color pigments?

While it can enhance brightness and opacity, it typically serves as a functional filler rather than a direct replacement for color pigments, which provide specific hues.

5. How can I ensure the quality of high-whiteness calcium carbonate?

Choose suppliers who adhere to strict quality control and provide documentation for their products, ensuring they meet industry standards and specifications.

Conclusion

High-whiteness calcium carbonate plays a pivotal role in enhancing the quality, performance, and aesthetic appeal of paints. Its unique properties offer a range of benefits, from improved opacity and cost-effectiveness to environmental sustainability. By understanding the advantages and applications of high-whiteness calcium carbonate, paint manufacturers can unlock its full potential, creating superior products that meet the demands of today’s market. As the industry continues to evolve, the use of high-whiteness calcium carbonate will undoubtedly remain a cornerstone in the formulation of innovative and high-quality paints.

high-whiteness calcium carbonate

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.