10

2025

-

04

Unlocking the Benefits of Colloidal Nano Calcium Carbonate in Industrial Applications

Unlocking the Benefits of Colloidal Nano Calcium Carbonate in Industrial Applications Table of Contents 1. Introduction to Colloidal Nano Calcium Carbonate 2. Properties of Colloidal Nano Calcium Carbonate 3. Key Benefits of Using Colloidal Nano Calcium Carbonate 4. Industrial Applications of Colloidal Nano Calcium Carbonate 4.1 Paints and Coatings

Unlocking the Benefits of Colloidal Nano Calcium Carbonate in Industrial Applications

Table of Contents

- 1. Introduction to Colloidal Nano Calcium Carbonate

- 2. Properties of Colloidal Nano Calcium Carbonate

- 3. Key Benefits of Using Colloidal Nano Calcium Carbonate

- 4. Industrial Applications of Colloidal Nano Calcium Carbonate

- 5. Challenges in Using Colloidal Nano Calcium Carbonate

- 6. Future Trends in Colloidal Nano Calcium Carbonate Use

- 7. Conclusion

- 8. Frequently Asked Questions (FAQs)

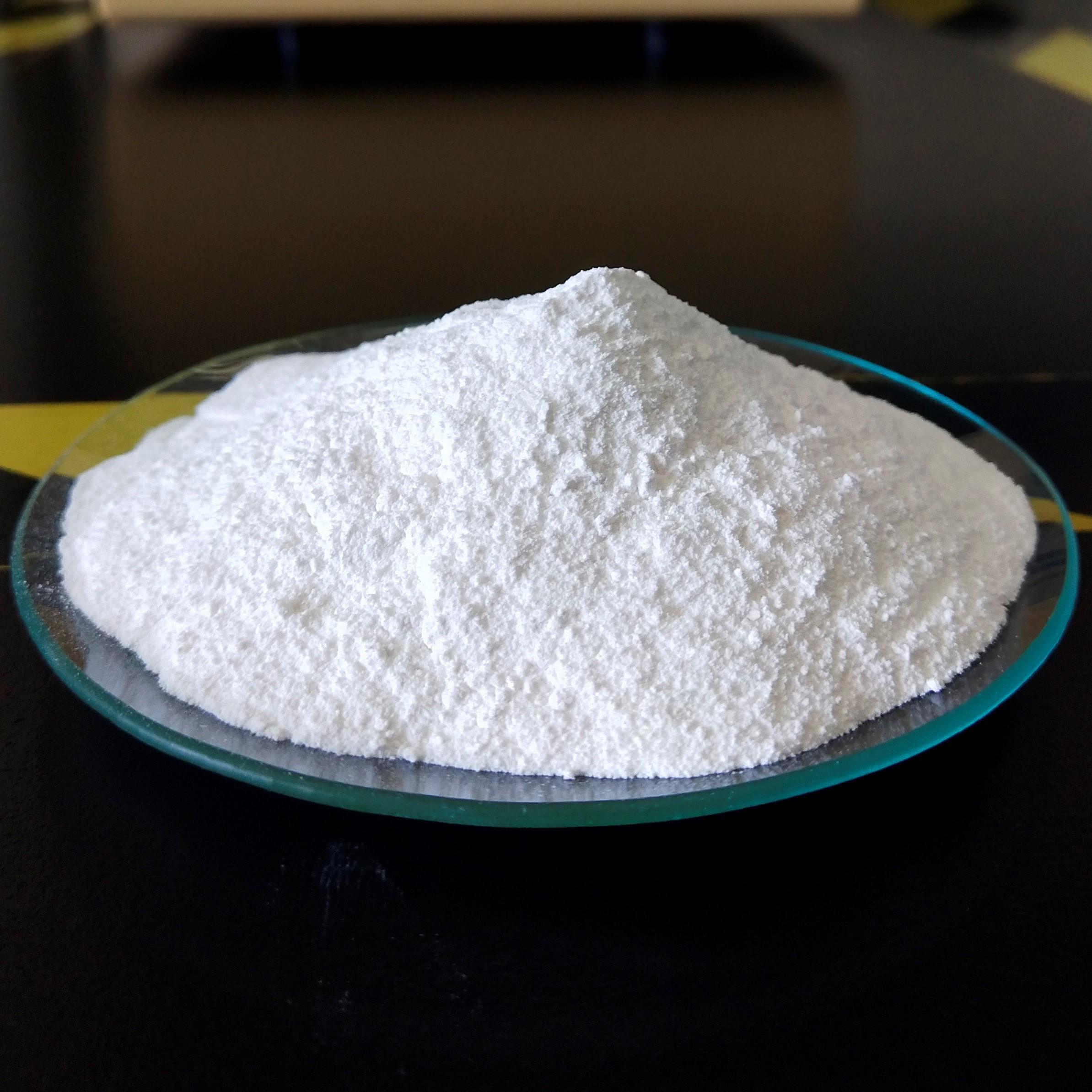

1. Introduction to Colloidal Nano Calcium Carbonate

Colloidal nano calcium carbonate (CaCO3) has emerged as a game-changer in various industrial sectors due to its unique properties and versatility. With its ultra-fine particle size, this form of calcium carbonate offers significant advantages over traditional counterparts. As industries strive for innovation and efficiency, colloidal nano calcium carbonate has positioned itself as a crucial additive that enhances product performance, sustainability, and cost-effectiveness.

In this article, we will delve into the myriad benefits of colloidal nano calcium carbonate, its industrial applications, and the future trends shaping its use in the chemical, paint, plastics, rubber, and paper industries.

2. Properties of Colloidal Nano Calcium Carbonate

Colloidal nano calcium carbonate possesses several distinct properties that set it apart from standard calcium carbonate. These properties include:

2.1 Particle Size and Surface Area

The particle size of colloidal nano calcium carbonate typically ranges from 1 to 100 nanometers. This ultra-fine size results in a remarkably high surface area, allowing for greater interaction with other materials. Such characteristics significantly enhance its effectiveness as a filler and a reinforcing agent in various applications.

2.2 Dispersion Stability

Colloidal nano calcium carbonate exhibits excellent dispersion stability in various solvents and matrices. This stability is crucial in ensuring uniformity in products such as paints, coatings, and plastics, leading to improved performance and appearance.

2.3 Non-toxic and Environmentally Friendly

As a naturally occurring mineral, colloidal nano calcium carbonate is non-toxic and environmentally friendly. Its use aligns with the growing demand for sustainable materials in industrial applications, making it a preferred choice for manufacturers aiming to reduce their ecological footprint.

2.4 Versatility as a Filler

Colloidal nano calcium carbonate acts as an effective filler in numerous products, enhancing the mechanical properties while potentially reducing production costs. Its versatility allows it to be used across various industries without compromising product quality.

3. Key Benefits of Using Colloidal Nano Calcium Carbonate

The benefits of incorporating colloidal nano calcium carbonate into industrial applications are numerous:

3.1 Enhanced Product Performance

Colloidal nano calcium carbonate improves the mechanical properties of materials, providing better tensile strength, impact resistance, and durability. This enhancement is particularly beneficial in applications such as plastics and rubber, where product longevity is paramount.

3.2 Cost-Effectiveness

The use of colloidal nano calcium carbonate can help manufacturers reduce costs by substituting more expensive materials without sacrificing quality. Its high efficiency as a filler means that less material is needed to achieve the same results, leading to overall savings.

3.3 Improved Aesthetic Qualities

In the paint and coating industries, colloidal nano calcium carbonate contributes to superior gloss, brightness, and color retention. This enhancement not only improves the visual appeal of products but also their marketability.

3.4 Environmentally Sustainable Options

With a growing emphasis on sustainability, colloidal nano calcium carbonate provides an eco-friendly alternative to synthetic fillers. Its natural origin and biodegradability align with modern manufacturing practices that prioritize environmental responsibility.

3.5 Compatibility with Various Materials

Colloidal nano calcium carbonate is compatible with a wide range of polymers and solvents, making it a versatile additive in various industrial formulations. This compatibility expands its applications, further solidifying its position in the marketplace.

4. Industrial Applications of Colloidal Nano Calcium Carbonate

Colloidal nano calcium carbonate finds extensive use across multiple industries:

4.1 Paints and Coatings

In the paints and coatings sector, colloidal nano calcium carbonate serves as a vital ingredient that enhances the product's texture, stability, and coverage. By improving the viscosity and flow properties, manufacturers can achieve better application finishes while utilizing fewer resources.

4.2 Plastics Industry

The plastics industry benefits significantly from colloidal nano calcium carbonate, which acts as a reinforcing agent. It enhances the mechanical properties of plastic materials, improving rigidity and toughness while simultaneously reducing weight. This dual advantage is crucial for producing lightweight yet durable plastic products.

4.3 Rubber Manufacturing

Colloidal nano calcium carbonate is extensively used in rubber manufacturing, where it contributes to improved flexibility, tear resistance, and processing efficiency. Its fine particle size allows for uniform distribution within the rubber matrix, resulting in superior product quality.

4.4 Paper Production

In paper production, colloidal nano calcium carbonate is utilized as a filler to enhance the brightness and opacity of paper products. By improving the printing properties and reducing production costs, it plays a vital role in optimizing paper manufacturing processes.

5. Challenges in Using Colloidal Nano Calcium Carbonate

Despite its numerous benefits, there are challenges associated with the use of colloidal nano calcium carbonate:

5.1 Cost of Production

The production of colloidal nano calcium carbonate can be more expensive than conventional calcium carbonate due to the advanced technology and processes involved. This cost factor can pose challenges for manufacturers seeking to adopt this innovative material.

5.2 Handling and Storage Issues

Due to its ultra-fine particle size, colloidal nano calcium carbonate may present handling and storage difficulties. Ensuring proper dispersion and preventing agglomeration requires careful management during storage and processing.

5.3 Regulation and Compliance

As with any industrial additive, regulatory compliance and safety assessments are crucial. Manufacturers must ensure that colloidal nano calcium carbonate meets industry standards and regulations to ensure safe usage in products.

6. Future Trends in Colloidal Nano Calcium Carbonate Use

The future of colloidal nano calcium carbonate appears promising, driven by ongoing research and technological advancements. Key trends include:

6.1 Innovations in Production Techniques

Advancements in production methods will likely lead to more cost-effective and efficient manufacturing processes for colloidal nano calcium carbonate. This innovation will make it more accessible to a broader range of industries.

6.2 Increased Demand for Sustainable Materials

As sustainability continues to be a priority for manufacturers, the demand for eco-friendly materials like colloidal nano calcium carbonate is expected to rise. Its attributes align well with the growing trend toward sustainable practices across various sectors.

6.3 Expanded Applications

Colloidal nano calcium carbonate is likely to find new applications in emerging industries, such as bioplastics and advanced coatings. As research continues to uncover its potential, the range of uses is expected to broaden significantly.

7. Conclusion

Colloidal nano calcium carbonate stands at the forefront of industrial innovation, offering a multitude of benefits that drive performance and sustainability across various sectors. Its unique properties, cost-effectiveness, and versatility make it an invaluable additive in paints, plastics, rubber, and paper production. As industries continue to prioritize quality and eco-friendliness, colloidal nano calcium carbonate is poised to play a vital role in shaping the future of manufacturing.

8. Frequently Asked Questions (FAQs)

8.1 What is colloidal nano calcium carbonate?

Colloidal nano calcium carbonate is an ultra-fine form of calcium carbonate with particle sizes ranging from 1 to 100 nanometers, known for its high surface area and effective properties as a filler and reinforcing agent.

8.2 How is colloidal nano calcium carbonate produced?

Colloidal nano calcium carbonate is produced through various methods, including precipitation and mechanical milling, which create ultra-fine particles with specific characteristics tailored for industrial applications.

8.3 What industries use colloidal nano calcium carbonate?

Colloidal nano calcium carbonate is used in a variety of industries, including paints and coatings, plastics, rubber manufacturing, and paper production, due to its diverse benefits and properties.

8.4 Is colloidal nano calcium carbonate environmentally friendly?

Yes, colloidal nano calcium carbonate is a naturally occurring mineral that is non-toxic and biodegradable, making it an eco-friendly option for manufacturers seeking sustainable materials.

8.5 What are the challenges of using colloidal nano calcium carbonate?

Challenges include the higher production costs compared to conventional calcium carbonate, handling and storage difficulties due to its fine particle size, and the need for regulatory compliance.

This comprehensive exploration of colloidal nano calcium carbonate underscores its tremendous potential and value in industrial applications. As industries evolve, embracing innovations like colloidal nano calcium carbonate will be key to achieving enhanced performance and sustainability in products and processes.

colloidal nano calcium carbonate

Next page

Get in Touch with Us Today

EZ Chemical is one of the best suppliers of calcium carbonate series products in China.

CONTACT US

E-mail: kevin_song@ezchemical.cn

ADD:Room 2008, Building 8, Jinse Yangguang, Xin'an East Road, Xin'anjiang Street, Jiande City, Zhejiang Province, China.